Introduction: Navigating the Global Market for timer feeder

In today’s competitive landscape, sourcing the right timer feeder can be a daunting task for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying quality products that meet specific operational needs but also in navigating a myriad of suppliers and pricing structures. This comprehensive guide aims to demystify the global market for timer feeders by exploring various types, applications, and essential features, empowering buyers to make informed decisions.

From automatic deer feeders designed to attract wildlife during daylight hours to versatile pet feeders catering to both cats and dogs, the timer feeder market is diverse and expanding. This guide will delve into the nuances of selecting the right equipment, including supplier vetting processes, cost considerations, and installation requirements. With practical insights and actionable strategies, buyers will gain a clearer understanding of how to align their purchasing choices with operational goals.

Our aim is to equip you with the knowledge to confidently navigate the complexities of the timer feeder market, ensuring your investments yield maximum returns. Whether you’re based in Nigeria or Germany, this guide serves as a valuable resource for sourcing reliable, high-quality timer feeders tailored to your specific business needs.

Spis treści

- Top 6 Timer Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for timer feeder

- Understanding timer feeder Types and Variations

- Key Industrial Applications of timer feeder

- 3 Common User Pain Points for ‘timer feeder’ & Their Solutions

- Strategic Material Selection Guide for timer feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for timer feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘timer feeder’

- Comprehensive Cost and Pricing Analysis for timer feeder Sourcing

- Alternatives Analysis: Comparing timer feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for timer feeder

- Navigating Market Dynamics and Sourcing Trends in the timer feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of timer feeder

- Strategic Sourcing Conclusion and Outlook for timer feeder

- Ważne zastrzeżenia i warunki użytkowania

Understanding timer feeder Types and Variations

| Nazwa typu | Kluczowe cechy wyróżniające | Główne aplikacje B2B | Krótkie zalety i wady dla kupujących |

|---|---|---|---|

| Digital Timer Feeders | Programmable settings, multiple feeding times | Hunting, wildlife management | Plusy: Highly customizable; reliable performance. Wady: Higher initial cost; may require technical knowledge for setup. |

| Automatic Pet Feeders | Designed for domestic animals, varying meal portions | Veterinary clinics, pet boarding | Plusy: Convenient for pet care; reduces labor. Wady: Limited to specific animal types; may require frequent refills. |

| Gravity Feeders | Simple design, relies on gravity for feed distribution | Small farms, hobbyist use | Plusy: Low maintenance; cost-effective. Wady: Less control over feeding times; potential for feed waste. |

| Solar-Powered Feeders | Energy-efficient, eco-friendly design | Remote locations, eco-conscious buyers | Plusy: Reduces energy costs; sustainable option. Wady: Dependent on sunlight; may have limited capacity. |

| Timed Deer Feeders | Programmable for specific times, often weather-resistant | Hunting lodges, wildlife reserves | Plusy: Attracts deer effectively; minimizes waste. Wady: Higher price point; may require batteries or power source. |

What Are Digital Timer Feeders and Their Benefits for B2B Buyers?

Digital timer feeders are advanced feeding systems that allow users to program specific feeding schedules and portions. These feeders typically feature multiple feeding times and can be tailored to meet the dietary needs of various wildlife. For B2B buyers in the hunting and wildlife management sectors, these feeders provide a reliable and efficient way to attract game animals, ensuring a consistent supply of food without frequent manual intervention. However, the initial cost may be higher, and some technical knowledge might be necessary for optimal setup.

How Do Automatic Pet Feeders Serve Veterinary Clinics and Pet Boarding?

Automatic pet feeders are designed to dispense food at predetermined times, making them ideal for veterinary clinics and pet boarding facilities. These feeders can manage various meal portions and accommodate both wet and dry food. For B2B buyers, the convenience of automated feeding reduces labor costs and ensures pets receive timely meals, which is vital for their health. However, these feeders may require regular maintenance and refilling, particularly in high-demand environments.

Why Choose Gravity Feeders for Small Farms or Hobbyist Use?

Gravity feeders are straightforward devices that rely on gravity to dispense feed. They are particularly suited for small farms or hobbyist applications where simplicity and low maintenance are key. B2B buyers appreciate the cost-effectiveness and ease of use, but they should consider that gravity feeders offer less control over feeding times and may lead to feed waste if not monitored closely.

What Are the Advantages of Solar-Powered Feeders for Remote Locations?

Solar-powered feeders are an eco-friendly solution that harnesses solar energy to operate, making them ideal for remote locations where electricity may be unavailable. For businesses focused on sustainability, these feeders reduce energy costs and environmental impact. However, B2B buyers should consider their dependence on sunlight and potential limitations in feed capacity, especially in less sunny regions.

How Do Timed Deer Feeders Enhance Hunting Experience?

Timed deer feeders are designed to dispense feed at specific times, attracting deer during daylight hours for hunting purposes. These feeders are often weather-resistant and can hold significant amounts of feed, making them suitable for hunting lodges and wildlife reserves. B2B buyers find them beneficial for increasing hunting success rates, but they come with a higher price point and may require batteries or a power source to operate effectively.

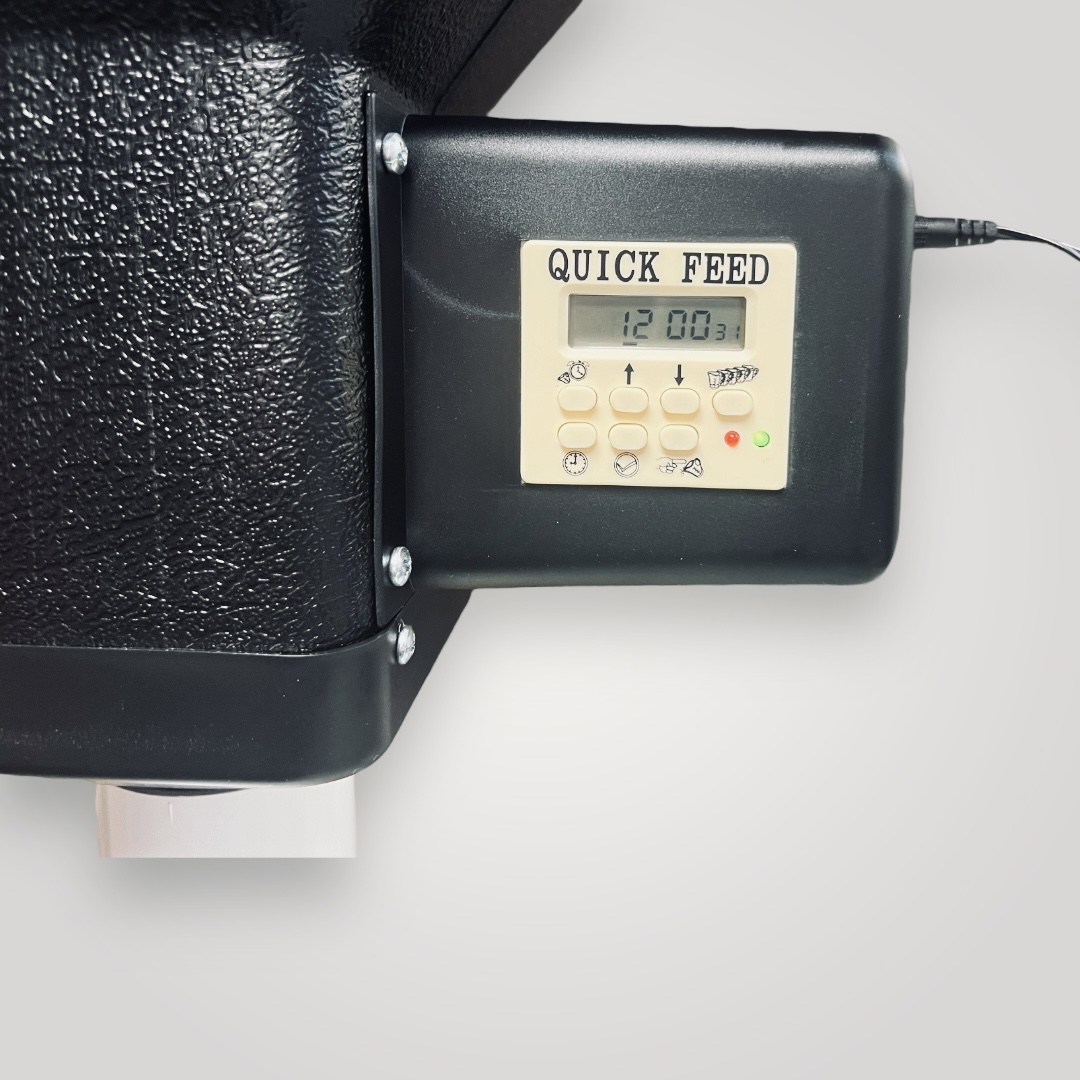

Illustrative image related to timer feeder

Key Industrial Applications of timer feeder

| Przemysł/sektor | Specific Application of Timer Feeder | Wartość/korzyść dla firmy | Kluczowe kwestie związane z zaopatrzeniem dla tej aplikacji |

|---|---|---|---|

| Rolnictwo | Livestock Feeding | Ensures timely and consistent feeding, improving animal health | Durability in harsh climates, battery life, and ease of use |

| Wildlife Management | Game Feeding for Hunting | Attracts wildlife during optimal hours, enhancing hunting success | Weather resistance, feed capacity, and programmability |

| Aquaculture | Fish Feeding | Automates feeding schedules, reducing labor costs | Compatibility with various fish species, feed type, and size |

| Pet Care | Automatic Pet Feeders for Cats and Dogs | Provides precise feeding times, ensuring pet health | Size versatility, food type compatibility, and ease of cleaning |

| Research Institutions | Controlled Feeding for Animal Studies | Facilitates consistent dietary studies, ensuring reliable data | Precision in feeding amounts, programmability, and reliability |

How is Timer Feeder Used in Agriculture for Livestock Feeding?

In agriculture, timer feeders are utilized for livestock feeding to ensure animals receive their feed at designated times. This automation is crucial for maintaining consistent nutrition, which directly affects livestock health and productivity. Buyers in this sector should consider the durability of the feeder, especially in harsh climates typical of regions in Africa or South America, as well as battery life for remote locations where electricity may be unreliable.

What Role Does Timer Feeder Play in Wildlife Management for Game Feeding?

In wildlife management, timer feeders are essential for game feeding, particularly in hunting scenarios. These feeders can be programmed to dispense food at specific times, attracting wildlife during daylight hours, which increases the chances of successful hunts. Buyers should prioritize features such as weather resistance and feed capacity to minimize the frequency of refills, especially in regions like the Middle East where environmental conditions can be extreme.

How is Timer Feeder Beneficial in Aquaculture for Fish Feeding?

In aquaculture, timer feeders automate the feeding process for fish, allowing for precise control over feeding schedules. This automation not only reduces labor costs but also ensures that fish receive the correct amount of feed at the right times, promoting optimal growth. For international buyers, considerations should include the compatibility of feeders with different fish species and the type of feed used, as well as the feeder’s size to accommodate various aquaculture setups.

How Can Timer Feeders Improve Pet Care Operations?

In the pet care industry, timer feeders are widely used to provide automatic feeding for cats and dogs. These devices allow pet owners to set specific meal times, ensuring pets receive their food consistently, which is vital for their health. When sourcing these products, businesses should consider the versatility of sizes and compatibility with different food types, as well as the ease of cleaning and maintenance, particularly for buyers in Europe where pet ownership is high.

Illustrative image related to timer feeder

What is the Importance of Timer Feeders in Research Institutions for Animal Studies?

Research institutions often use timer feeders to control feeding schedules for animals in dietary studies. This precision is critical for obtaining reliable data on animal behavior and health outcomes. Buyers in this sector must focus on the programmability of feeders to ensure accurate portion sizes and feeding times, as well as the overall reliability of the product to withstand frequent use in a laboratory environment.

3 Common User Pain Points for ‘timer feeder’ & Their Solutions

Scenario 1: Difficulty in Setting Up Timer Feeders for Diverse Environments

Problem: B2B buyers often face challenges when installing timer feeders in varying environmental conditions. For instance, a company operating in regions with extreme weather, like heavy rains or intense heat, may find that standard feeders do not perform adequately. This can lead to equipment failure, wasted feed, and ultimately, financial losses. Moreover, the complexity of installation can deter users who may not have the technical expertise, leading to improper use and even safety hazards.

Rozwiązanie: To address these installation challenges, it’s crucial to source timer feeders that are specifically designed for diverse environmental conditions. Look for feeders that feature weather-resistant materials and components that can withstand harsh climates. When purchasing, ensure that the product specifications highlight easy installation features, such as clear instructions and necessary tools included in the package. It may also be beneficial to seek out manufacturers that offer on-site support or installation guides. Additionally, investing in training for staff on how to set up and maintain these feeders can greatly enhance their effectiveness and longevity. This proactive approach can help businesses avoid costly setbacks and ensure that their feeding operations run smoothly.

Scenario 2: Inconsistent Feed Dispensing Leading to Animal Health Issues

Problem: Inconsistent feed dispensing from timer feeders can lead to significant issues, particularly in agricultural settings where animal health is paramount. A B2B buyer may experience situations where the timer feeder malfunctions, resulting in either too much or too little feed being dispensed. This inconsistency can cause malnutrition in livestock or attract unwanted pests, further complicating operations.

Rozwiązanie: To mitigate the risk of inconsistent feed dispensing, buyers should prioritize timers with reliable mechanisms and quality control features. Look for products that include adjustable dispensing schedules and portion control settings. Regular maintenance checks, including battery replacements and software updates, are essential to ensure optimal performance. Furthermore, establishing a monitoring system, such as periodic checks of feed levels and animal behavior, can help identify issues before they escalate. Some manufacturers also offer remote monitoring capabilities, allowing buyers to track dispenser performance in real time, which can provide peace of mind and support proactive decision-making.

Scenario 3: Limited Warranty and Support Services Causing Frustration

Problem: A common pain point for B2B buyers is the lack of robust warranty and customer support services from timer feeder manufacturers. When equipment fails, businesses may find themselves stuck with unresponsive customer service or insufficient warranty coverage, leading to prolonged downtime and lost revenue. This situation is particularly critical for companies that rely on timely feeding schedules for livestock or wildlife management.

Rozwiązanie: To alleviate concerns regarding warranty and support, B2B buyers should conduct thorough research before purchasing timer feeders. Seek out manufacturers known for their customer service reputation and those that provide comprehensive warranties that cover both parts and labor. It’s also beneficial to inquire about the availability of replacement parts and whether the manufacturer has a dedicated customer support line. Establishing a relationship with suppliers who offer training and troubleshooting resources can further enhance support levels. Engaging with online forums or communities can provide additional insights into the reliability of different brands and their support offerings, helping buyers make informed decisions that safeguard their investments.

Strategic Material Selection Guide for timer feeder

What Are the Common Materials Used in Timer Feeders?

When selecting materials for timer feeders, it’s essential to consider their properties, advantages, and limitations. The right material can significantly affect the feeder’s performance, durability, and overall user satisfaction. Here, we analyze four common materials used in timer feeders: plastic, aluminum, stainless steel, and fiberglass.

How Does Plastic Perform in Timer Feeders?

Plastic is a widely used material in timer feeders due to its lightweight and cost-effective nature. Key properties include good corrosion resistance and the ability to withstand a range of temperatures, making it suitable for various climates. However, plastic may not be as durable as metal options and can degrade over time when exposed to UV light.

Plusy: Cost-effective, lightweight, and resistant to corrosion.

Wady: Less durable than metals, potential UV degradation.

Wpływ na aplikację: Suitable for environments with moderate temperature fluctuations but may not hold up in extreme conditions.

For international buyers, particularly in regions like Africa and South America, compliance with local regulations regarding plastic use is crucial. Buyers should also consider the availability of recycled materials, which may align with sustainability goals.

What Are the Advantages of Aluminum in Timer Feeders?

Aluminum is another popular choice for timer feeders, known for its excellent strength-to-weight ratio and corrosion resistance. It can withstand higher temperatures and pressures, making it suitable for various operational environments.

Illustrative image related to timer feeder

Plusy: Lightweight, strong, and highly resistant to corrosion.

Wady: Higher cost compared to plastic and may require additional coatings for UV protection.

Wpływ na aplikację: Ideal for outdoor use where exposure to moisture and temperature variations are common.

International buyers, especially from Europe, should ensure that aluminum products meet relevant standards such as DIN for quality assurance. Additionally, the lightweight nature of aluminum can reduce shipping costs, appealing to buyers in remote areas.

Why Is Stainless Steel a Preferred Material for Timer Feeders?

Stainless steel is often regarded as the premium choice for timer feeders due to its exceptional durability and resistance to corrosion and rust. It can handle extreme temperature variations, making it suitable for diverse climates and applications.

Plusy: Extremely durable, corrosion-resistant, and aesthetically pleasing.

Wady: Higher initial cost and heavier than plastic or aluminum.

Wpływ na aplikację: Excellent for long-term use in harsh environments, reducing the frequency of replacements.

For B2B buyers in the Middle East, where high temperatures and humidity are common, stainless steel’s resilience is a significant advantage. Compliance with international standards like ASTM for stainless steel grades is essential for ensuring product quality.

Illustrative image related to timer feeder

How Does Fiberglass Compare in Timer Feeders?

Fiberglass is a composite material that combines strength and lightweight properties, making it an excellent choice for timer feeders. It offers good resistance to corrosion and can withstand various environmental conditions.

Plusy: Lightweight, strong, and resistant to corrosion.

Wady: Can be more expensive than plastic and may require specialized manufacturing techniques.

Wpływ na aplikację: Suitable for environments where chemical exposure is a concern, such as agricultural settings.

International buyers should consider the manufacturing standards for fiberglass in their regions, as compliance can vary. In Europe, for instance, adherence to EU regulations on composite materials is crucial.

Summary of Material Selection for Timer Feeders

| Materiał | Typical Use Case for timer feeder | Kluczowa zaleta | Kluczowa wada/ograniczenie | Koszt względny (niski/średni/wysoki) |

|---|---|---|---|---|

| Tworzywo sztuczne | Budget-friendly feeders | Cost-effective and lightweight | Less durable than metals | Niski |

| Aluminum | Outdoor feeders | Strong and corrosion-resistant | Higher cost | Średni |

| Stainless Steel | High-end, long-lasting feeders | Extremely durable and aesthetic | Heavy and expensive | Wysoki |

| Fiberglass | Chemical-resistant applications | Lightweight and corrosion-resistant | More expensive | Średni |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for timer feeders, ensuring informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for timer feeder

What Are the Main Stages of Manufacturing a Timer Feeder?

The manufacturing process of a timer feeder is intricate and involves several key stages, each critical to ensuring the final product meets performance and quality standards. Understanding these stages can help B2B buyers assess the reliability and efficiency of potential suppliers.

1. Material Preparation

The first step in manufacturing timer feeders involves selecting and preparing raw materials. Common materials include durable plastics for the housing, metals for the internal components, and electronic circuits for the timer mechanisms. Suppliers often perform a quality check on the materials to ensure they meet specific standards, such as corrosion resistance and durability. This stage may also involve sourcing components from certified vendors, ensuring that all materials comply with international safety and quality regulations.

2. Forming Techniques

Once the materials are prepared, the next step is forming. This includes processes such as injection molding for plastic components and stamping or machining for metal parts. Advanced techniques like CNC machining may be utilized for precision parts, ensuring that all components fit together seamlessly. During this phase, it’s crucial to maintain strict tolerances to avoid issues during assembly.

Illustrative image related to timer feeder

3. Assembly Process

The assembly of timer feeders typically involves both manual and automated processes. Technicians or robots assemble the electronic components, integrate the timer systems, and secure the housing. This stage is vital, as improper assembly can lead to malfunctioning feeders. Some manufacturers employ modular assembly lines, which allow for flexibility and efficiency. Each assembly line should be regularly maintained and assessed to ensure optimal performance.

4. Finishing Touches

After assembly, the timer feeders undergo finishing processes, including painting, coating, and final inspections. These processes not only enhance the aesthetic appeal but also provide additional protection against environmental factors such as moisture and UV exposure. Quality checks during this phase ensure that the timer feeders are free of defects and function as intended.

How Is Quality Assurance Implemented in Timer Feeder Manufacturing?

Quality assurance (QA) is integral to the manufacturing of timer feeders, ensuring that each product adheres to established standards and regulations. International and industry-specific certifications play a significant role in this process.

What International Standards Should B2B Buyers Look For?

Many manufacturers comply with ISO 9001, an internationally recognized standard that focuses on quality management systems. This certification indicates that the manufacturer has a robust framework for ensuring consistent quality and continuous improvement. Additionally, specific certifications like CE for European markets and API for oil and gas applications may apply, depending on the feeder’s intended use.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to maintain product integrity. These checkpoints typically include:

Illustrative image related to timer feeder

- Incoming Quality Control (IQC): This involves inspecting materials and components upon receipt to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process help identify and rectify issues early, minimizing waste and rework.

- Final Quality Control (FQC): Before packaging, each timer feeder undergoes comprehensive testing to verify its functionality, durability, and safety.

What Common Testing Methods Are Used in Timer Feeder QC?

Common testing methods for timer feeders include:

- Functional Testing: Ensures that the timer and feeding mechanisms operate correctly under various conditions.

- Environmental Testing: Assesses the feeder’s performance in extreme temperatures and humidity levels to ensure longevity.

- Safety Testing: Validates that the product meets safety standards, including electrical safety and material toxicity.

W jaki sposób nabywcy B2B mogą weryfikować kontrolę jakości dostawców?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure reliability and compliance with local regulations. Here are several strategies to achieve this:

What Audit Processes Can Be Utilized?

Conducting supplier audits is one of the most effective ways to assess quality control practices. Buyers should consider both initial audits and periodic follow-ups to ensure ongoing compliance. Audits can include:

- On-Site Inspections: Visiting the manufacturing facility to observe processes and evaluate conditions firsthand.

- Document Reviews: Evaluating quality management documentation, including procedures, records, and certifications.

What Reports and Certifications Should Buyers Request?

Buyers should request copies of relevant quality assurance documentation, including:

- Quality Control Plans: Detailed descriptions of the QC processes and checkpoints used by the manufacturer.

- Test Reports: Results from various testing phases that validate product performance and compliance.

- Certifications: Proof of compliance with international standards and regulations.

How Do Quality Control Nuances Affect International Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of regional regulatory nuances. Different countries may have specific requirements regarding product safety, environmental impact, and quality assurance. Buyers should familiarize themselves with local regulations and ensure that their suppliers can meet these demands.

Wnioski

Understanding the manufacturing processes and quality assurance protocols for timer feeders is crucial for B2B buyers looking to make informed purchasing decisions. By evaluating the stages of manufacturing and implementing rigorous quality control measures, suppliers can deliver reliable products that meet international standards. Buyers should leverage audits, documentation, and certifications to verify supplier capabilities, ensuring that they invest in high-quality timer feeders that will perform well in their intended applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘timer feeder’

Introduction

Sourcing a timer feeder for your business requires a strategic approach to ensure that you meet both operational needs and quality standards. This guide provides a step-by-step checklist designed for B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe. By following this checklist, you can streamline your procurement process and make informed decisions that align with your business objectives.

1. Identify Your Specific Needs

Before initiating the sourcing process, clearly define what you need from a timer feeder. Consider factors such as the type of feed, feeding frequency, and capacity requirements. This will help you narrow down your options and ensure that the products you evaluate meet your operational demands.

- Feeding Capacity: Determine how much feed you need the feeder to hold and dispense.

- Feeding Schedule: Decide how many times a day the feeder should dispense food.

2. Research Available Features and Technologies

Understanding the features of various timer feeders is crucial. Look for models that offer programmable settings, battery life, and ease of installation.

- Programmable Timers: Ensure the feeder allows for multiple feeding times and portions.

- Durability: Check if the feeder is weather-resistant and designed for outdoor use.

3. Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. This involves checking their credentials, product offerings, and customer feedback.

- Request Documentation: Ask for company profiles, case studies, and references.

- Assess Product Range: Ensure the supplier offers a variety of models to meet diverse needs.

4. Request Samples for Testing

Once you’ve identified potential suppliers, request samples of the timer feeders. Testing samples allows you to evaluate their performance in real-world conditions.

- Operational Testing: Assess the feeder’s functionality, ease of use, and reliability during testing.

- Compatibility Check: Ensure the feeder works with the feed types you intend to use.

5. Verify Compliance and Certifications

Confirm that the timer feeders comply with relevant industry standards and certifications. This is particularly important for international sourcing, as regulations may vary by region.

- Quality Certifications: Look for ISO or other quality assurance certifications.

- Safety Standards: Ensure the products meet safety regulations applicable in your target market.

6. Negotiate Terms and Conditions

Once you have selected a supplier, negotiate the terms of purchase. This includes pricing, payment terms, delivery schedules, and warranty conditions.

- Bulk Pricing: Inquire about discounts for larger orders.

- Warranty Coverage: Ensure there is adequate warranty coverage for the products.

7. Establish a Support and Maintenance Plan

Finally, discuss support and maintenance options with your supplier. A reliable support plan is crucial for ensuring the longevity of your timer feeders.

- Technical Support: Confirm that the supplier offers technical assistance for installation and troubleshooting.

- Replacement Parts: Ensure the supplier can provide replacement parts and accessories as needed.

By following these steps, B2B buyers can effectively navigate the procurement process for timer feeders, ensuring they select the best products that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for timer feeder Sourcing

What Are the Key Cost Components in Sourcing Timer Feeders?

When evaluating the cost structure for timer feeders, several components contribute to the overall expense. Materiały represent a significant portion, including durable plastics, metals for the housing, and electronic components like timers and motors. These materials need to be sourced from reliable suppliers to ensure quality and longevity, especially given the feeder’s outdoor use.

Labor costs are another critical factor, encompassing the workforce involved in assembly, testing, and quality control (QC). The complexity of the feeder design can influence labor intensity; more intricate systems require skilled labor, which can increase costs.

Manufacturing overhead includes expenses related to factory utilities, equipment maintenance, and administrative costs. Additionally, tooling costs for molds and specialized equipment can be substantial, particularly for custom designs or high-volume production runs.

Logistics costs must also be factored in, including shipping, handling, and warehousing. These can vary significantly based on the shipping method and the distance to the buyer’s location. Lastly, manufacturers typically build in a margin for profit, which can fluctuate based on competitive pressures and market demand.

How Do Price Influencers Impact Timer Feeder Costs?

Several factors influence the pricing of timer feeders in the B2B market. Volume and Minimum Order Quantity (MOQ) are critical; suppliers often offer discounts for larger orders, which can lower the per-unit price. Conversely, small orders may incur higher costs due to lower economies of scale.

Specifications and customization also play a role. Custom-designed feeders tailored to specific customer requirements often come with a higher price tag due to the additional development and manufacturing processes involved.

The quality of materials and any certifications (such as ISO or industry-specific standards) can significantly impact pricing. High-quality, certified components generally lead to higher costs but can result in greater durability and reliability, ultimately reducing the Total Cost of Ownership (TCO).

Supplier factors, including location, reputation, and production capacity, influence pricing as well. Suppliers in regions with lower labor costs may offer more competitive pricing but could compromise on quality.

Finally, understanding Incoterms is essential for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the final landed cost of the product.

What Tips Can International B2B Buyers Use for Cost-Efficiency in Timer Feeder Purchases?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency when sourcing timer feeders. Negotiation is key; engaging in discussions about pricing can yield significant savings, especially for bulk orders.

Understanding the Total Cost of Ownership is crucial. While the initial purchase price is important, buyers should consider long-term factors such as maintenance, durability, and the potential costs of downtime if the feeder fails. Choosing a slightly more expensive, high-quality feeder may result in lower overall costs over its lifespan.

When evaluating options, price nuances for international transactions must be considered. Fluctuations in exchange rates, shipping costs, and customs duties can all affect final pricing. Utilizing local representatives or agents familiar with the market can help navigate these complexities.

Illustrative image related to timer feeder

Lastly, buyers should request indicative pricing from multiple suppliers to benchmark costs effectively. This practice can help identify competitive offers and ensure that the buyer is making an informed decision based on comprehensive market analysis.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing timer feeder With Other Solutions

Introduction to Alternative Solutions for Timer Feeders

In the competitive landscape of feeding solutions for wildlife, particularly in regions like Africa, South America, the Middle East, and Europe, businesses must evaluate various options to optimize their operations. Timer feeders, designed to dispense food at scheduled intervals, are popular for their reliability and ease of use. However, alternatives such as gravity feeders and solar-powered feeders also present unique advantages. This analysis will compare these solutions to help B2B buyers identify the best fit for their specific needs.

Tabela porównawcza

| Aspekt porównawczy | Timer Feeder | Gravity Feeder | Solar-Powered Feeder |

|---|---|---|---|

| Wydajność | Accurate timing for consistent feeding | Passive feeding; reliant on gravity | Automated feeding using solar energy |

| Koszt | Moderate (typically $60-$150) | Lower initial cost (typically $30-$80) | Higher initial cost (typically $150-$300) |

| Łatwość wdrożenia | Easy to install with basic wiring | Simple setup; minimal assembly required | Requires solar panel installation |

| Konserwacja | Regular battery checks; occasional repairs | Minimal; mostly cleaning required | Requires monitoring of solar efficiency |

| Najlepszy przypadek użycia | Controlled feeding for specific wildlife | Ideal for areas with consistent wildlife | Best for remote areas with no electricity |

Detailed Breakdown of Alternatives

Gravity Feeders: What Are Their Strengths and Weaknesses?

Gravity feeders utilize the force of gravity to dispense food, making them a straightforward solution for wildlife feeding. They generally have a lower initial cost, making them accessible for businesses with tight budgets. The ease of maintenance is another advantage, as they require minimal intervention beyond regular cleaning. However, gravity feeders can be less reliable in terms of feeding frequency and may not attract wildlife as effectively as timer feeders, particularly in areas where feeding schedules are crucial for hunting or wildlife management.

Solar-Powered Feeders: Are They Worth the Investment?

Solar-powered feeders represent a modern approach, utilizing renewable energy to automate feeding schedules. Their ability to operate in remote areas without power infrastructure makes them particularly appealing for businesses operating in off-grid locations. However, the initial investment is higher than both timer and gravity feeders, which may be a barrier for some buyers. While they require some setup for solar panel installation, ongoing maintenance is generally low, focusing mainly on ensuring that the solar panels are unobstructed and functional. This option is ideal for businesses prioritizing sustainability and operational efficiency.

Illustrative image related to timer feeder

Conclusion: Choosing the Right Solution for Your Needs

When selecting a feeding solution, B2B buyers must assess their specific operational requirements and environmental conditions. Timer feeders offer precision and control, making them suitable for targeted feeding strategies. In contrast, gravity feeders provide a cost-effective and low-maintenance alternative that may suffice in less demanding scenarios. Meanwhile, solar-powered feeders offer an innovative, eco-friendly solution for remote locations. By weighing the performance, cost, ease of implementation, maintenance, and best use cases, buyers can make informed decisions that align with their strategic goals and resource capabilities.

Essential Technical Properties and Trade Terminology for timer feeder

What Are the Key Technical Properties of Timer Feeders?

1. Feed Capacity

Feed capacity refers to the amount of feed a timer feeder can hold, typically measured in pounds or kilograms. For example, some models may offer a capacity of 350 pounds, allowing for fewer refills and increased operational efficiency. Understanding feed capacity is crucial for B2B buyers as it directly affects the frequency of maintenance and the overall cost-effectiveness of the feeder over time.

2. Power Source

Timer feeders can be powered by batteries or mains electricity. Battery-operated models are beneficial in remote areas where electricity is unavailable. The choice of power source impacts installation flexibility and operational reliability, which are vital considerations for international buyers working in diverse environments across Africa, South America, and the Middle East.

3. Material Grade

The material grade of a timer feeder affects its durability and resistance to environmental elements. Common materials include high-density polyethylene (HDPE) and galvanized steel, which offer weather resistance and longevity. Selecting a feeder with the right material grade ensures that it can withstand local climatic conditions, thus minimizing replacement costs and ensuring consistent performance.

4. Timer Precision and Programming Options

Timer precision determines how accurately the feeder can dispense feed at scheduled intervals. Many advanced models offer programmable timers that allow users to set multiple feeding times throughout the day. This feature is essential for optimizing feeding strategies, particularly in agricultural settings where feeding schedules can significantly impact livestock growth and health.

5. Ease of Installation and Maintenance

A timer feeder should come with clear installation instructions and require minimal tools for setup. Features like a wiring harness and user-friendly interfaces enhance usability. This aspect is especially important for B2B buyers who may not have technical expertise, as it reduces the need for external installation services and lowers operational downtime.

What Are Common Trade Terms Used in the Timer Feeder Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another brand’s name. In the context of timer feeders, understanding OEM relationships can help buyers source high-quality components and ensure reliable supply chains, especially when considering bulk purchases.

Illustrative image related to timer feeder

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers, as it affects purchasing decisions and inventory management. Knowing the MOQ helps in budgeting and planning for stock levels, ensuring that businesses can meet their operational needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests price estimates from suppliers. This term is pivotal in B2B transactions as it allows buyers to compare costs, terms, and services from different manufacturers, facilitating informed decision-making and potentially leading to better pricing agreements.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs, which is crucial for businesses involved in cross-border trade of timer feeders. Familiarity with Incoterms can help mitigate risks and ensure smoother logistics.

5. Warranty and Service Agreements

Warranty terms indicate the duration and scope of coverage for defects or malfunctions in a product. Understanding warranty conditions and available service agreements is essential for B2B buyers to ensure long-term support and reliability of their timer feeders, minimizing potential downtime and repair costs.

By grasping these technical properties and industry terms, B2B buyers can make well-informed decisions when sourcing timer feeders, aligning product specifications with their operational requirements and regional conditions.

Illustrative image related to timer feeder

Navigating Market Dynamics and Sourcing Trends in the timer feeder Sector

What Are the Current Market Dynamics and Key Trends in the Timer Feeder Sector?

The timer feeder sector is currently experiencing robust growth driven by increasing demand for automated feeding solutions in agriculture and wildlife management. Global drivers include the rising need for efficiency in food distribution, particularly in regions with labor shortages or logistical challenges, such as Africa and South America. The integration of smart technology into feeding systems, including IoT-enabled feeders, is emerging as a key trend. This technology allows for remote monitoring and control, enhancing user convenience and operational efficiency.

International B2B buyers, especially from Europe and the Middle East, are increasingly focused on sourcing high-quality, durable products that can withstand diverse environmental conditions. The popularity of solar-powered timer feeders is also on the rise, aligning with the global shift toward renewable energy solutions. In addition, the emergence of e-commerce platforms facilitates easier access to global suppliers, allowing buyers to compare products and prices efficiently.

The competitive landscape is further influenced by evolving consumer preferences for features such as customizable feeding schedules and advanced durability. As buyers become more informed about product options, suppliers are encouraged to innovate and differentiate their offerings, enhancing the overall market dynamics.

Illustrative image related to timer feeder

How Is Sustainability and Ethical Sourcing Influencing the Timer Feeder Market?

Sustainability is increasingly becoming a focal point in the timer feeder sector, with B2B buyers prioritizing products that minimize environmental impact. The use of recyclable materials and energy-efficient components is gaining traction, as companies seek to align with global sustainability goals. Buyers are increasingly seeking suppliers who can demonstrate a commitment to ethical sourcing practices, including fair labor conditions and environmentally responsible manufacturing processes.

Certifications such as ISO 14001 (Environmental Management) and other ‘green’ labels are becoming essential for suppliers looking to capture the attention of conscientious buyers. The demand for products that contribute to sustainable practices, such as feeders designed to reduce feed waste and prevent overfeeding, is also growing. By prioritizing sustainability, companies can enhance their brand reputation and attract a broader customer base.

Moreover, the pressure to adopt sustainable practices extends beyond product offerings. B2B buyers are scrutinizing the entire supply chain, looking for transparency and accountability from manufacturers. This shift towards sustainability is not just a trend but a necessary evolution in the market, as buyers increasingly recognize the long-term benefits of ethical sourcing.

What Is the Brief Evolution of Timer Feeders in the Market?

The timer feeder has evolved significantly over the years, transitioning from simple manual devices to sophisticated automated systems. Initially designed for agricultural use, the concept gained traction in wildlife management as hunters and conservationists recognized the benefits of controlled feeding schedules. Early models were rudimentary, relying on mechanical timers and basic feeding mechanisms.

Illustrative image related to timer feeder

As technology advanced, manufacturers began incorporating digital timers and programmable settings, allowing for more precise feeding intervals. The introduction of solar power and IoT capabilities has further revolutionized the sector, enabling users to monitor and adjust feeding schedules remotely via smartphone applications. This evolution not only enhances user convenience but also reflects the broader trend of integrating technology into traditional agricultural practices, making timer feeders a vital tool in modern wildlife management and farming.

In conclusion, the timer feeder market is at a pivotal point, driven by technological innovation and a growing emphasis on sustainability. International B2B buyers must navigate these dynamics to make informed sourcing decisions that align with their operational needs and ethical values.

Frequently Asked Questions (FAQs) for B2B Buyers of timer feeder

-

How do I solve issues with my timer feeder not dispensing food properly?

To troubleshoot a timer feeder that isn’t dispensing food, first check the power source and ensure the batteries are functioning. Inspect the timer settings to confirm they are programmed correctly for the desired feeding times. Additionally, examine the food compartment for blockages or jams, and make sure the feeder is clean to avoid contamination. If the problem persists, consult the manufacturer’s manual for specific troubleshooting steps or reach out to customer support for assistance. -

What is the best timer feeder for deer hunting?

The best timer feeder for deer hunting will depend on your specific needs, including the size of your feeding area and the frequency of feeding. Look for models that allow multiple feeding times per day, have a large feed capacity, and are weather-resistant. Additionally, consider feeders with features like adjustable feed amounts and a built-in battery indicator. Reviews from other hunters can also provide valuable insights into performance and reliability in real-world conditions. -

What are the minimum order quantities (MOQ) for timer feeders when sourcing from international suppliers?

Minimum order quantities (MOQ) for timer feeders vary by supplier and can range from a few units to several hundred. When sourcing, inquire directly with the supplier about their MOQ, as this can influence your purchasing strategy and inventory management. Some suppliers may offer lower MOQs for first-time buyers or promotional periods, making it beneficial to establish a relationship and negotiate terms that suit your business needs. -

How can I verify the reliability of a supplier for timer feeders?

To verify a supplier’s reliability, conduct thorough research by checking their business history, customer reviews, and ratings on B2B platforms. Request references from previous clients to understand their experiences. Additionally, consider visiting the supplier’s manufacturing facility if feasible, or participating in trade shows to meet them in person. Evaluating their certifications, such as ISO standards or compliance with local regulations, can further assure you of their credibility. -

What payment terms should I expect when sourcing timer feeders internationally?

Payment terms for international sourcing of timer feeders typically include options like advance payment, letters of credit, or payment upon delivery. Standard practice often involves a deposit (e.g., 30-50%) upfront, with the balance due before shipment or upon delivery. Be sure to clarify the payment options available with your supplier, as well as any additional fees for international transactions. Always use secure payment methods to protect your investment. -

What shipping options are available for timer feeders, and how can I choose the best one?

Shipping options for timer feeders generally include air freight, sea freight, and express courier services. The best choice depends on your budget, urgency, and volume of the order. Air freight is faster but more expensive, making it suitable for urgent needs, while sea freight is cost-effective for larger shipments but takes longer. Always discuss shipping terms with your supplier, including delivery times and insurance options, to ensure that your order arrives safely and on time. -

How do I ensure quality assurance (QA) for timer feeders from international suppliers?

To ensure quality assurance for timer feeders, establish clear quality standards and specifications before placing an order. Request samples to evaluate the product’s quality firsthand. It’s also advisable to include quality control measures in your purchase agreement, such as inspections at the factory before shipment. Additionally, consider working with third-party inspection services to verify product quality and compliance with your standards before accepting the delivery. -

Can timer feeders be customized for specific needs or branding?

Many manufacturers offer customization options for timer feeders, including modifications in size, color, and features to meet specific requirements. Branding customization, such as adding your company logo, is also common. When contacting suppliers, clearly communicate your customization needs and inquire about any additional costs or lead times associated with these changes. Customization can enhance your product’s appeal and better serve your target market, making it a worthwhile investment.

Top 6 Timer Feeder Manufacturers & Suppliers List

1. Closer Pets – Automatic Cat Feeders

Domena: closerpets.com

Registered: 2020 (5 years)

Wprowadzenie: Automatic Cat Feeders: 15 products available. Features include scheduling meals, compartments for wet/dry food, and battery-powered operation. Prices range from $17.99 to $247.98. Free shipping on orders over $49. Specific products include: MiBowl Automatic Microchip Pet Feeder (CP500) – $129.99 (regular $199.99), Cat Mate C500 – 5 Meal Digital Automatic Feeder – $45.99 (regular $49.99), Closer Pe…

2. Redneck – Programmable Timed Dispenser for 750 lb Gravity Feeder

Domena: redneckblinds.com

Registered: 2010 (15 years)

Wprowadzenie: Programmable Timed Dispenser for 750 lb Gravity Feeder

– Price: $134.99 (originally $149.99)

– Designed for 750 lb Fiberglass Gravity Deer Feeder

– Mounts onto the frame of the existing feeder

– Programmable controller deposits feed into four gravity tubes (holds approx. 15 lbs of feed each)

– Feeds 1 to 8 times per day

– Run time per feeding: 1 to 30 seconds

– Test run option available

– Programm…

3. Premier Pet – Automatic Timer Pet Feeder – 2 Meal

Domena: premierpet.com

Registered: 2003 (22 years)

Wprowadzenie: {“product_name”: “Automatic Timer Pet Feeder – 2 Meal”, “sku”: “GFD00-17006”, “features”: {“meal_count”: “2 meals within a 24-hour period”, “capacity”: “3 cups total, adjustable portion control up to 1.5 cups per meal”, “food_type”: “dry or semi-moist food”, “design”: “simple-to-use timer design”, “security”: “tamper-resistant lids”, “quiet_function”: “quiet lid function”, “material”: “BPA-free, d…

4. CatMate – Automatic Cat Feeder with Timer

Domena: reddit.com

Registered: 2005 (20 years)

Wprowadzenie: Looking for an auto feeder with a timer for a cat. Desired features include: releases food at a specific time, has a storage compartment, and includes a metal bowl attachment (to avoid cat acne from plastic bowls). The feeder should only work with dry food, as wet food is given for dinner. Bonus points for a beep or chime noise when food is released. Concerns include clogging, size of the opening,…

5. West Texas Feeders – THE TIMER TWO STAGE Game Feeder Control

Domena: elusivewildlife.com

Registered: 2005 (20 years)

Wprowadzenie: {“product_name”: “THE TIMER TWO STAGE Game Feeder Control”, “brand”: “West Texas Feeders”, “price”: “$99.99”, “warranty”: “5 years”, “compatibility”: “Compatible with any 6 Volt or 12 Volt control unit”, “feeding_frequency”: “Can feed up to six times a day”, “features”: [“Fuse protected”, “Two-motor wiring harness”, “Extra pigtails”, “AA batteries included”], “dimensions”: “4in x 3in x 6in”, “weig…

6. Petlibro – Automatic Pet Feeders

Domena: petlibro.com

Registered: 2019 (6 years)

Wprowadzenie: Automatic Pet Feeders for Cats and Dogs – Petlibro offers various models including Polar Smart Wet Food Feeder, Granary Seamless Dry Food Feeders, and Air Smart Feeders. Key features include RFID pet recognition, vacuum sealing technology, app control, and dual food trays. Capacity options range from 2L to 8L. Prices vary from $89.99 to $449.97 with discounts available. Free shipping on orders ove…

Strategic Sourcing Conclusion and Outlook for timer feeder

What Are the Key Benefits of Strategic Sourcing for Timer Feeders?

In conclusion, strategic sourcing of timer feeders presents significant advantages for international B2B buyers. By prioritizing high-quality products, such as the advanced timer systems and durable materials showcased in today’s market, businesses can enhance their operational efficiency and reduce waste. For example, timers that allow for multiple feeding schedules not only optimize feed usage but also improve the overall hunting experience.

Furthermore, engaging with reputable suppliers ensures access to innovative solutions that can adapt to diverse environments, particularly in regions like Africa, South America, the Middle East, and Europe. These markets are increasingly recognizing the importance of sustainability and efficiency in sourcing practices, making it imperative for buyers to invest in reliable products.

How Can International Buyers Prepare for Future Trends in Timer Feeders?

Looking ahead, the demand for technologically advanced timer feeders is expected to grow, driven by a focus on precision feeding and automation. B2B buyers should stay informed about emerging trends, such as smart feeding technology and eco-friendly designs, to remain competitive. By taking proactive steps now to build partnerships with forward-thinking manufacturers, businesses can position themselves at the forefront of this evolving market.

Embrace the opportunity to elevate your operations—invest in strategic sourcing for timer feeders today and set your business up for long-term success.

Ważne zastrzeżenia i warunki użytkowania

⚠️ Ważne zastrzeżenie

Informacje zawarte w niniejszym przewodniku, w tym treści dotyczące producentów, specyfikacji technicznych i analizy rynku, służą wyłącznie celom informacyjnym i edukacyjnym. Nie stanowią one profesjonalnego doradztwa w zakresie zamówień, doradztwa finansowego ani doradztwa prawnego.

Chociaż dołożyliśmy wszelkich starań, aby zapewnić dokładność i aktualność informacji, nie ponosimy odpowiedzialności za jakiekolwiek błędy, pominięcia lub nieaktualne informacje. Warunki rynkowe, szczegóły firmy i standardy techniczne mogą ulec zmianie.

Nabywcy B2B muszą przeprowadzić własną, niezależną i dokładną analizę due diligence przed podjęciem decyzji o zakupie. Obejmuje to bezpośredni kontakt z dostawcami, weryfikację certyfikatów, prośbę o próbki i zasięgnięcie profesjonalnej konsultacji. Ryzyko polegania na jakichkolwiek informacjach zawartych w niniejszym przewodniku ponosi wyłącznie czytelnik.

Illustrative image related to timer feeder