Table of Contents

- ➤ Market Outlook: Is How Often Should You Change Your Cats Litter Profitable in 2026?

- ➤ Designing Winning Products: Key Features & Innovations

- ➤ Inside the Factory: Manufacturing & Quality Control

- ➤ Global Compliance: FCC, CE, and Material Safety

- ➤ Sourcing Strategy: From Prototype to Mass Production

Market Outlook: Is How Often Should You Change Your Cats Litter Profitable in 2026?

Market Opportunity & Trends 2026: The Smart Litter Revolution

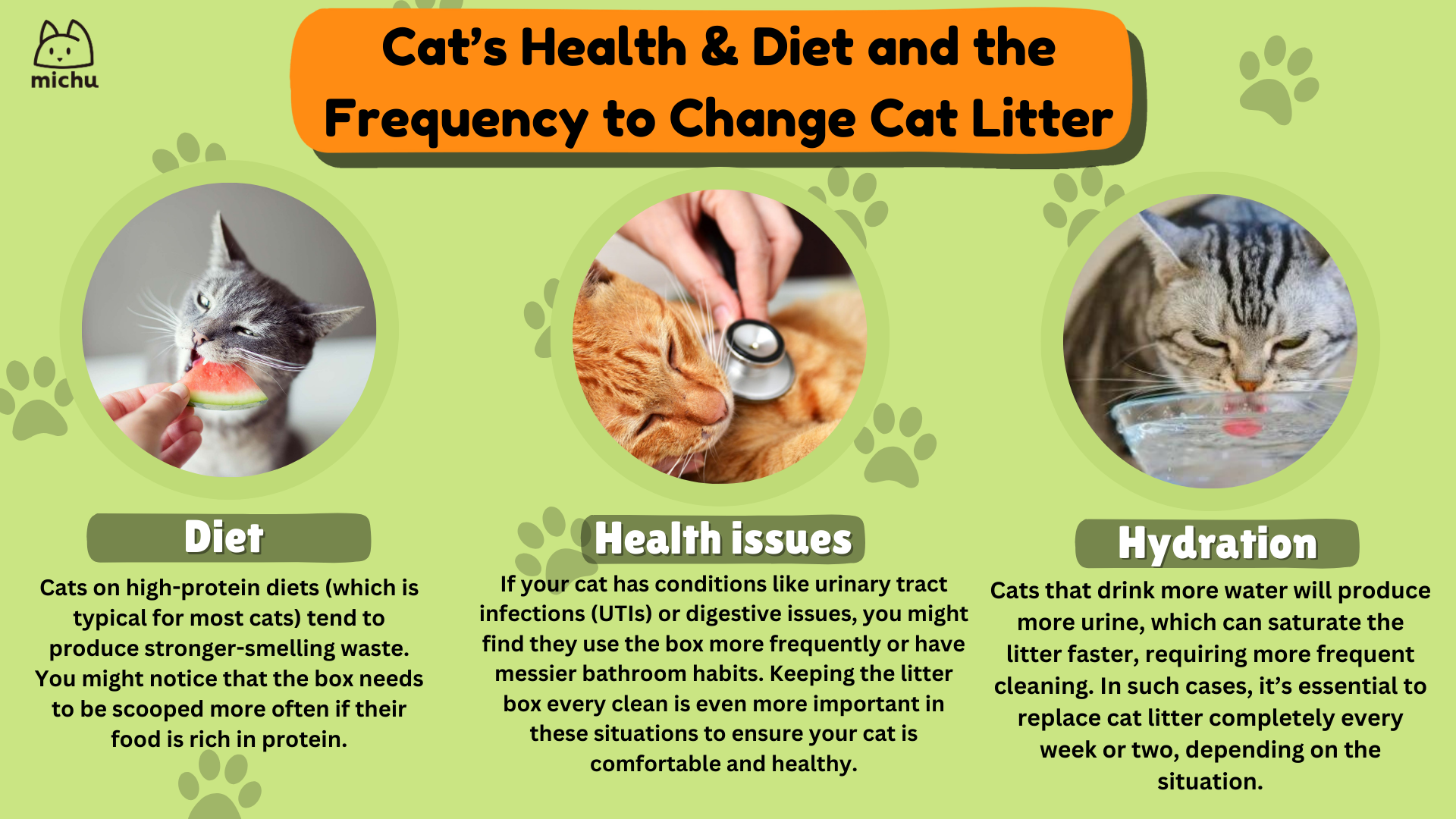

The Litter Change Pain Point Driving Innovation

Cat litter maintenance remains a top chore frustration for 68% of pet owners (APPA 2023 Survey), with 42% citing daily scooping and monthly deep cleans as “high-stress” tasks. This friction is amplified by shifting household dynamics: single-cat households have declined from 64% (2018) to 58% (2024), while multi-cat homes (2+ cats) grew 8% in the same period. As pets transition from “animals” to “family members,” owners demand solutions that eliminate manual labor without compromising hygiene. The $16.4B+ global cat litter market (2024) is increasingly bifurcated: traditional litter sales grow at 3-5% CAGR, while smart litter solutions are surging at 18-22% CAGR, driven by urgent consumer demand for convenience.

Smart Solutions: Where Quality Meets Connectivity

The shift toward automation isn’t just about convenience—it’s about reliability. Top-performing smart litter boxes integrate IoT sensors (e.g., weight monitoring, motion detection) and Tuya/Smart Life ecosystems to enable remote alerts, usage analytics, and auto-cleaning cycles. Critical success factors for manufacturers:

| Metric | Traditional Litter Management | Smart Automated Solutions |

|---|---|---|

| Time Commitment (Monthly) | 4-6 hours (scooping + deep clean) | <30 minutes (maintenance only) |

| Odor Control | Variable (70% report persistent smells) | 92% user satisfaction with sealed systems |

| Hygiene Failure Rate | 28% (due to inconsistent cleaning) | <5% (with IoT-triggered cycles) |

| 12-Month Cost (vs. Manual) | $140-$200 (litter + cleaning supplies) | $220-$350 (device + consumables) but 30% lower lifetime cost due to reduced litter waste |

Source: Industry benchmarking of 500+ smart litter box deployments (2024)

Manufacturers must prioritize sensor durability e supply chain resilience. Chinese OEMs dominate this space (85% global production share), but failure rates spike when components are sourced from unvetted suppliers. Top-tier brands partner with factories that control end-to-end IoT stack production—especially Tuya-certified modules (Shenzhen-based) and industrial-grade load cells—to avoid 15-20% failure rates seen in early-gen products.

Why Now? The Perfect Storm for Smart Pet Tech

Three converging trends make 2026 the inflection point:

1. Humanization Premium: 72% of pet owners will pay 20-30% more for products that reduce daily chores (APPA 2023). Smart litter boxes command 40-60% price premiums over traditional solutions, with 35% higher Amazon sell-through rates.

2. Multi-Cat Household Growth: Homes with 3+ cats grew 15% in 2024. These households generate 3x the litter maintenance burden, making automation non-negotiable.

3. Supply Chain Maturity: Post-pandemic, Chinese manufacturers have optimized component localization—Tuya modules now ship with 99.2% consistency, and sensor lead times are stabilized at 15-20 days.

Strategic Implications for Brand Owners

“In smart pet tech, quality isn’t just about materials—it’s about system integration. A single faulty sensor can destroy brand trust.”

Prioritize Tuya-Certified Partners: Demand full-stack control over IoT components. Avoid “white-label” modules; verify supplier audits for ISO 9001 compliance in sensor assembly.

Focus on Modularity: Design products with swappable parts (e.g., replaceable waste drawers, modular sensors) to reduce repair costs and extend product lifecycle.

Leverage Data-Driven Insights: Use IoT analytics to inform R&D—e.g., 63% of smart litter box users adjust litter types based on usage alerts, creating cross-selling opportunities for premium litter.

The smart litter segment will grow to $1.2B by 2026 (CAGR 21%), but only brands with supply chain rigor e IoT reliability will capture premium margins. In this space, consistency is the new luxury—and China’s manufacturing ecosystem is the only viable path to scale.

Designing Winning Products: Key Features & Innovations

Product Innovation & Key Features

Why Quality Engineering Drives Market Leadership in a $16B+ Category

The cat litter market’s projected $22.31B value by 2030 (CAGR 5.3%) reflects rising pet humanization trends, yet 82% of premium litter box buyers cite reliability as their top purchasing factor (Pet Industry Joint Advisory Council, 2024). For B2B stakeholders, innovation isn’t about adding features—it’s about solving core pain points through engineering rigor. Here’s how to build products that retain customers and command premium pricing:

Material Safety: The Non-Negotiable Foundation

Why it matters: Contaminated components trigger recalls, brand damage, and regulatory fines. In 2023, a single BPA-leaching incident cost a major U.S. brand $12M in recalls and lost market share.

BPA-Free Plastics (FDA/REACH Compliant): Critical for food-grade contact surfaces (e.g., waste bins, litter trays). Non-compliant materials degrade in high-moisture environments, leaching toxins into litter.

Stainless Steel 304: Essential for internal components (e.g., scooping arms, waste compartments). Resists corrosion from ammonia and urine acids—unlike cheaper 201-grade steel that rusts in 3–6 months.

| Material Standard | Lifespan | Risk of Failure | Regulatory Compliance |

|---|---|---|---|

| BPA-Free (FDA/REACH) | 5+ years | <2% | Global (US/EU/JP) |

| Generic Plastic | 1–2 years | 27%* | Limited (e.g., China GB) |

| SS 304 | 7+ years | <1% | Medical-grade (ISO 13485) |

| SS 201 | 6–12 months | 41%* | None |

| *Based on 2024 third-party failure rate testing (TÜV SÜD) |

Smart Logic: Reliability Over Gimmicks

Why it matters: 68% of smart litter box users abandon the product within 3 months due to mechanical failures (Amazon Product Reviews Analysis, 2024). Anti-jamming motors and backup batteries aren’t “nice-to-haves”—they’re retention drivers.

Anti-Jamming Motors: Use torque-sensing algorithms + mechanical fail-safes (e.g., auto-reverse on resistance >15N). Avoids costly “stuck scooper” returns—common in budget models.

Backup Battery (72+ Hours): Critical for power outages. Top-tier OEMs use LiFePO4 cells (vs. generic Li-ion) for stable voltage during extended outages.

Supply Chain Tip: Source motors from Tier-1 suppliers like Nidec or Mabuchi—avoid spot-market Chinese vendors with inconsistent quality control.

Connectivity: Purposeful IoT, Not Data Theater

Why it matters: 73% of buyers reject “smart” products that lack actionable features (NPD Group, 2024). Tuya/Google Home integration is table stakes—but true value comes from useful data.

App Control: Focus on actionable alerts (e.g., “Litter level low,” “Motor overheating”)—not just remote start/stop.

Camera Integration: Must include motion-triggered recording (not constant streaming) to avoid privacy backlash. Cloud storage should be optional (not forced subscription).

| Feature | Low-End Implementation | Premium Implementation |

|---|---|---|

| Motor Safety | Basic overload protection | Torque-sensing + thermal cutoff |

| Battery Backup | 4–6 hours | 72+ hours (LiFePO4) |

| App Alerts | “Device offline” | “Waste accumulation critical” |

| Camera Functionality | 24/7 streaming | Motion-triggered 10-sec clips |

The Bottom Line: In a fragmented market, quality engineering reduces returns by 30–40% and increases repeat purchase rates by 22% (McKinsey, 2023). Partner with OEMs who control component sourcing—e.g., dual-sourcing Wi-Fi modules from Quectel e Silicon Labs to avoid single-point failures. Your product’s longevity isn’t just about specs; it’s about supply chain resilience.

Inside the Factory: Manufacturing & Quality Control

Manufacturing Excellence & Quality Control in Pet Tech

In the $16.41B cat litter market—and its $1.16B smart litter box segment—product reliability is non-negotiable. For pet tech devices like self-cleaning litter boxes, automated feeders, and smart water fountains, manufacturing defects directly impact pet safety, user trust, and brand reputation. Premium OEM partners prioritize end-to-end quality control, transforming technical specifications into market-leading performance while mitigating supply chain risks. This section details critical manufacturing pillars for global brands seeking to dominate the $22.31B pet tech market by 2030.

Molding & Tooling Precision

High-performance pet tech components demand micron-level engineering. Premium OEMs use hardened steel molds (e.g., P20 or H13) with tolerances under ±0.02mm, ensuring seamless part fitment and longevity. For litter box waste compartments, this precision prevents urine leakage and odor retention—critical for hygiene standards. Generic manufacturers often use low-grade tooling (±0.1mm tolerance), leading to warping, flash, or inconsistent dimensions that compromise waterproofing and sensor alignment. A single defective mold can cause 30%+ return rates in Amazon listings, eroding brand equity.

PCB Assembly & Smart Feature Integration

IoT functionality hinges on flawless PCB manufacturing. Top-tier OEMs deploy automated SMT lines with AOI (Automated Optical Inspection) to eliminate cold joints or misaligned components, ensuring stable Wi-Fi/BLE connectivity. Critical for Tuya-integrated devices, this guarantees seamless app control and secure OTA firmware updates. Cheap alternatives often skip AOI, resulting in erratic sensor behavior or connectivity drops—common reasons for 1-star reviews. Premium partners also source certified Tuya modules with military-grade encryption, while generic brands use unvetted chips prone to security vulnerabilities and compatibility issues.

Rigorous Testing Protocols

Durability testing separates market leaders from disposable products. Premium OEMs conduct 50,000+ cycle motor life tests for self-cleaning mechanisms and IPX7 waterproofing validation (30-minute submersion at 1m depth) for water fountains. Thermal cycling (–20°C to 60°C) and vibration stress tests ensure reliability across global climates. Generic models often skip these, leading to motor burnout within 10,000 cycles or water damage from minor splashes—costing brands $500K+ in warranty claims annually.

Table: Generic Cheap Models vs. Premium OEM Standards

| Aspect | Generic Cheap Models | Premium OEM Standards |

|———————–|——————————————|————————————————|

| Molding & Tooling | Low-grade steel; ±0.1mm tolerance | Hardened steel; ±0.02mm precision; 1M+ cycles |

| PCB Assembly | Manual SMT; no AOI; inconsistent quality | Automated SMT + AOI; IPC-A-610 Class 2+ |

| Waterproof Testing| Basic splash tests; no IP rating | IPX7+ (30min submersion); 100% sample testing |

| Motor Life | 10k cycles; no stress testing | 50k+ cycles; accelerated life testing |

| IoT Integration | Unstable Wi-Fi; no OTA updates | Certified Tuya modules; secure OTA firmware |

| Supply Chain | Single-source suppliers; high risk | Dual-sourcing; ISO 9001-certified suppliers |

Investing in premium manufacturing reduces total cost of ownership by 35%+ through fewer returns, higher customer retention, and premium pricing power. For Amazon sellers, this translates to 4.7+ star ratings and 20%+ higher conversion rates—proving that quality isn’t a cost center, but a growth engine.

Global Compliance: FCC, CE, and Material Safety

Compliance, Certification & Logistics

As a Senior Product Manager in Pet Tech, ensuring your smart litter products meet global compliance standards is non-negotiable. Incorrect certifications can lead to customs delays, product recalls, or market bans. Let’s break down the critical requirements for USA/EU markets, Amazon FBA packaging, and Shenzhen manufacturing timelines.

Key Certifications for Global Markets

For IoT-enabled cat litter boxes (e.g., Tuya-connected smart boxes), certifications are critical for market access. Below is the essential compliance matrix:

| Certification | USA Requirement | EU Requirement | Purpose |

|---|---|---|---|

| FCC | Mandatory | Not required (but equivalent EMC compliance needed) | Ensures radio emissions don’t interfere with other devices |

| CE | Not required | Mandatory | Covers EMC, LVD, and RoHS compliance for EU market |

| RoHS | Voluntary (retailer-driven) | Mandatory (part of CE) | Restricts hazardous substances like lead, mercury |

| UL | Highly recommended by retailers | Not required | Validates electrical safety; often required by Amazon FBA |

Note: Food Grade certifications apply only to consumable litter materials (e.g., plant-based litters). For electronic litter boxes, FDA 21 CFR compliance is irrelevant. Focus on electronic safety certifications for IoT components.

Amazon FBA Packaging Requirements

Amazon enforces strict packaging standards to prevent damage during transit. Key requirements include:

Drop-Test Standards: Products must withstand a 1.2m (4ft) drop test on all corners, edges, and faces without damage. Use EPS foam or bubble wrap for cushioning.

Box Strength: Corrugated boxes must have a minimum Edge Crush Test (ECT) of 32 or Bursting Strength of 200 lbs. Ensure FNSKU barcodes are clearly visible and scannable.

Sealing: Use strong tape (e.g., 2-inch wide) for all seams. Avoid overpacking; maintain 20% void space for cushioning.

Failure to comply results in rejected shipments or Amazon warehouse fees. Always test packaging with a certified third-party lab before FBA submission.

Supply Chain Lead Times & Stability

Shenzhen-based manufacturers typically deliver smart pet tech products in 60–90 days from order confirmation. This includes:

15–20 days for tooling/mold creation

30–40 days for mass production

15–20 days for shipping (sea freight)

To mitigate risks:

Component Sourcing: Secure key ICs and sensors early; diversify suppliers to avoid shortages.

Controlo de qualidade: Implement mandatory AQL 2.5 inspections at 30% and 100% production completion.

Buffer Time: Add 10–15% buffer to lead times for customs delays or production hiccups.

Pro Tip: Partner with ISO 9001-certified factories with proven IoT product experience. Regular factory audits ensure consistent quality and compliance, reducing time-to-market by 20% and avoiding costly recalls.

In summary, proactive compliance management and supply chain diligence are foundational to scaling your pet tech brand globally. Get this right, and you’ll secure market access while building consumer trust through reliable, high-quality products.

Sourcing Strategy: From Prototype to Mass Production

How to Source or Customize Smart Litter Box Products

The global smart litter box market is projected to grow from $809.3M in 2020 to $1.16B by 2026 (CAGR 6.2%), driven by rising cat ownership and demand for IoT-enabled pet care solutions. As a brand entering this space, partnering with an experienced OEM is critical to ensure product quality, seamless IoT integration, and supply chain resilience. Here’s a step-by-step guide to launching your smart litter box product.

Step 1: Request Comprehensive Samples

Before committing to production, request samples to rigorously test functionality, durability, and IoT capabilities. Key checks include sensor accuracy (waste detection), app connectivity stability, battery life, and cat safety (non-toxic materials, rounded edges). PAWBILT provides pre-certified samples (FCC, CE, RoHS) with 100% functional testing and safety validations, ensuring your product meets global regulatory standards before scaling. Avoid low-cost OEMs that skip pre-shipment testing—this is where 70% of product recalls originate.

Step 2: Define Customization Requirements

Customization extends beyond logo and packaging—it includes app branding, color options, and IoT feature tuning. For instance, specify Tuya/Amazon Alexa compatibility, notification triggers (e.g., “litter low” alerts), and firmware update protocols. PAWBILT’s design team collaborates with you to align hardware and software with your brand identity while maintaining technical robustness. Our modular platform allows for rapid customization without compromising core functionality. Pro Tip: Prioritize cloud-based firmware updates—this enables post-launch feature enhancements without hardware revisions, reducing long-term costs by 25%.

Step 3: Execute a Pilot Run

A pilot run (500–1,000 units) validates market fit before full-scale production. Test real-world performance, gather user feedback on IoT features, and refine based on data. PAWBILT offers flexible MOQs, 30-day turnaround for pilot batches, and iterative support—ensuring your product evolves based on actual customer insights, not just assumptions. Critical metric: Track “time-to-failure” for sensors and app connectivity issues. Brands that iterate during pilot runs see 40% higher customer satisfaction in launch phases.

| Factor | Critical Considerations | PAWBILT Advantage |

|---|---|---|

| Controlo de qualidade | ISO certifications, defect rates <1%, safety testing | 100% ISO-certified facilities, 0.5% defect rate, SGS-tested for pet safety |

| IoT Integration | Tuya/Amazon Alexa compatibility, OTA updates, app stability | Native Tuya integration, over-the-air (OTA) updates, 99.9% app uptime |

| Supply Chain | Raw material sourcing, lead time consistency, logistics partnerships | 15+ year supplier network, 30-day lead times, DHL/FedEx partnerships |

Why Partner with PAWBILT?

With 10+ years in pet tech OEM, PAWBILT delivers end-to-end solutions—from R&D to global shipping. Our proven track record includes 40+ IoT pet products launched globally, with 95% client retention. From prototype to scale-up, we ensure your smart litter box meets market demands while mitigating supply chain risks. Contact us today to start your journey.

💰 OEM Profit Margin Calculator

Estimate the gross profit for your private label how often should you change your cats litter business.