Introduction: Navigating the Global Market for when to change hummingbird feeder

In the dynamic landscape of global bird feeding, understanding when to change hummingbird feeders is a crucial aspect for B2B buyers. With varying climates and seasonal patterns across regions, such as Africa, South America, the Middle East, and Europe, the optimal timing for nectar replacement can significantly impact both the health of the birds and the effectiveness of feeding strategies. This guide delves into the nuances of hummingbird feeder maintenance, offering insights into types of feeders available, their applications across different environments, and essential supplier vetting practices.

As a B2B buyer, your ability to source quality products while ensuring optimal feeder management will directly influence customer satisfaction and sales performance. We will explore the recommended frequency for changing nectar, considerations for different weather conditions, and best practices for keeping feeders clean and effective. Additionally, we will provide a framework for evaluating suppliers, taking into account cost, product quality, and sustainability practices.

By leveraging this comprehensive guide, international buyers will be empowered to make informed purchasing decisions that not only meet regulatory standards but also enhance the overall experience for bird enthusiasts. This strategic approach ensures that your offerings remain competitive and aligned with the needs of diverse markets, ultimately fostering a thriving business in the global hummingbird feeder market.

Table Of Contents

- Top 3 When To Change Hummingbird Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for when to change hummingbird feeder

- Understanding when to change hummingbird feeder Types and Variations

- Key Industrial Applications of when to change hummingbird feeder

- 3 Common User Pain Points for ‘when to change hummingbird feeder’ & Their Solutions

- Strategic Material Selection Guide for when to change hummingbird feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for when to change hummingbird feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘when to change hummingbird feeder’

- Comprehensive Cost and Pricing Analysis for when to change hummingbird feeder Sourcing

- Alternatives Analysis: Comparing when to change hummingbird feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for when to change hummingbird feeder

- Navigating Market Dynamics and Sourcing Trends in the when to change hummingbird feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of when to change hummingbird feeder

- Strategic Sourcing Conclusion and Outlook for when to change hummingbird feeder

- Important Disclaimer & Terms of Use

Understanding when to change hummingbird feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seasonal Change | Adjusts nectar types based on seasonal availability | Bird feeding supply companies, retailers | Pros: Aligns with hummingbird migration patterns. Cons: Requires inventory management for seasonal products. |

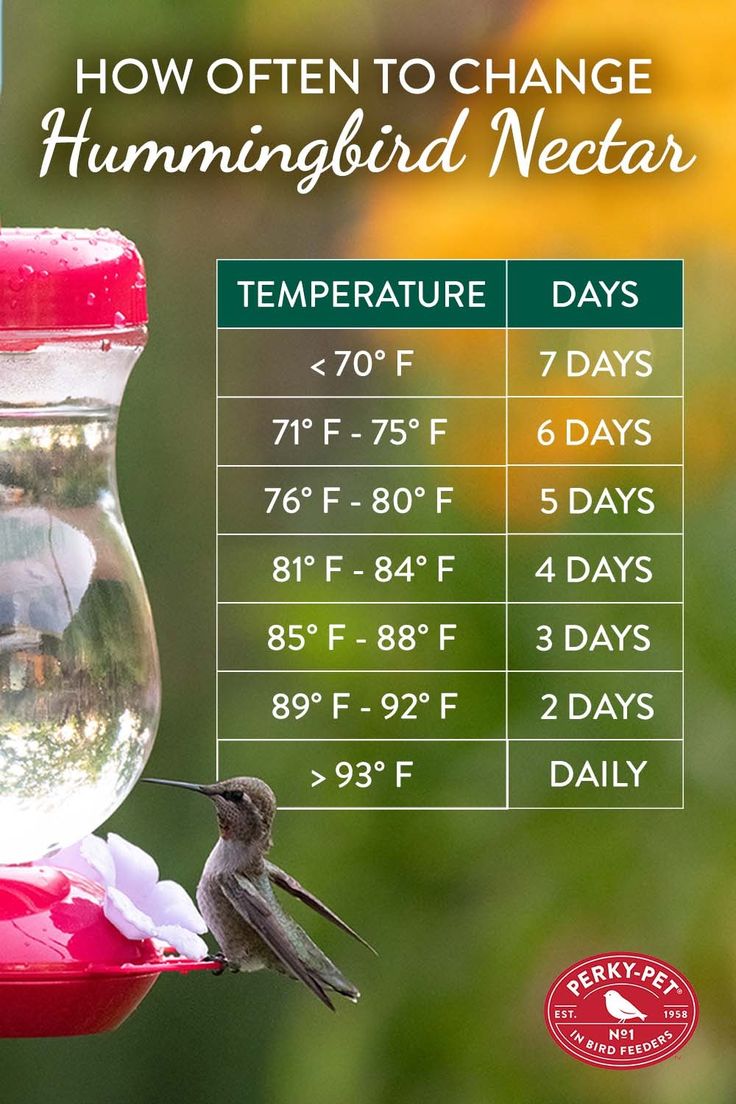

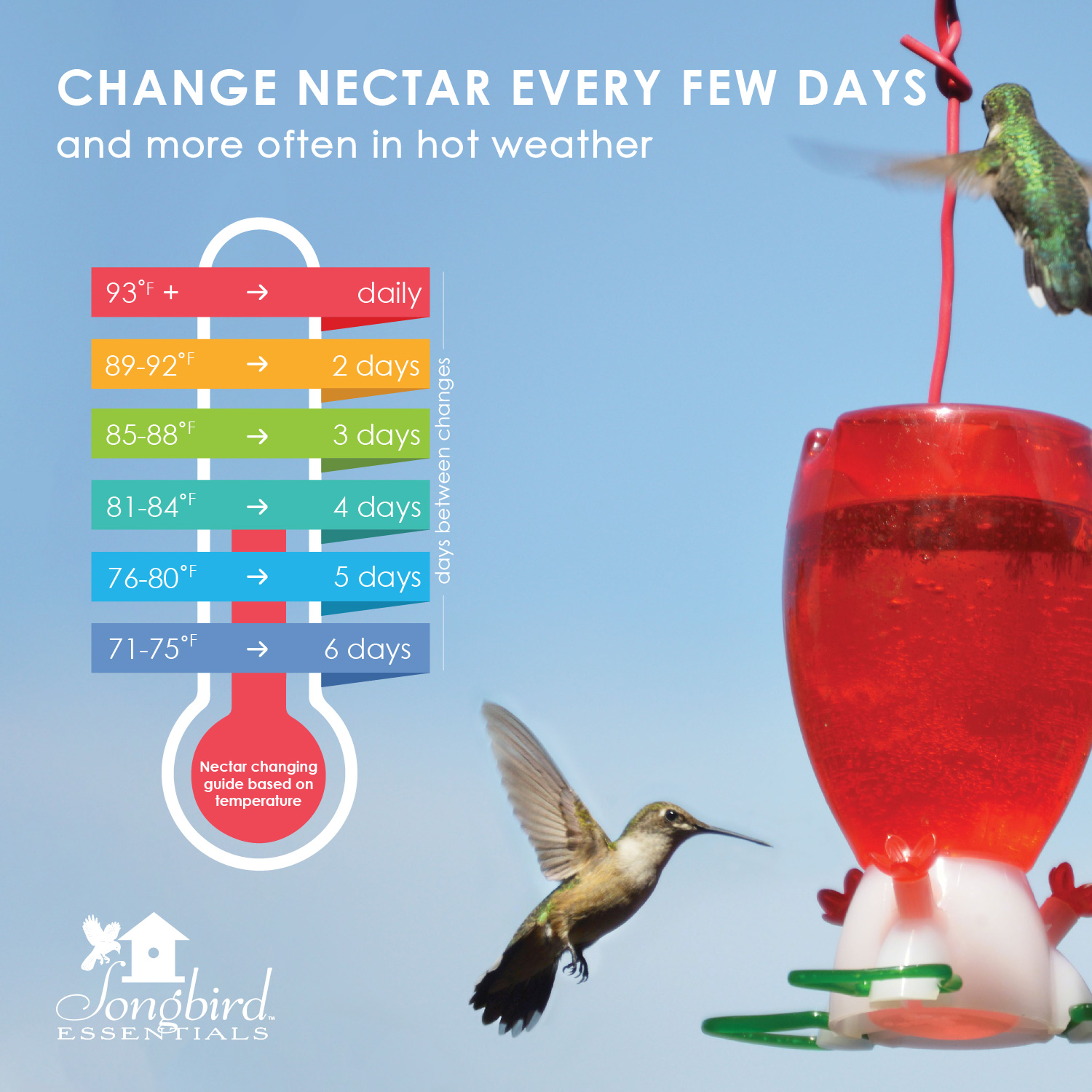

| Temperature-Based Change | Frequency of nectar change dictated by weather | Outdoor gear suppliers, ecological retailers | Pros: Ensures nectar freshness in varying climates. Cons: Increased labor for frequent changes in warm climates. |

| Type of Feeder Variation | Different feeder designs necessitating varied care | Manufacturers of specialized feeders | Pros: Tailored solutions for specific bird species. Cons: Complexity in product offerings for retailers. |

| Nectar Composition Change | Adjusting sugar-water ratios based on flower mimicry | Nectar manufacturers, specialty food suppliers | Pros: Mimics natural food sources for hummingbirds. Cons: Requires education for consumers on proper ratios. |

| Maintenance and Cleaning Cycle | Regular cleaning schedules to prevent mold and spoilage | Bird feeder retailers, cleaning product suppliers | Pros: Enhances bird health and feeder longevity. Cons: May deter some consumers due to perceived maintenance effort. |

What Are the Key Features of Seasonal Change in Hummingbird Feeders?

Seasonal change involves adjusting the nectar type or feeder design based on the seasonal patterns of hummingbird migration. This is particularly relevant for B2B buyers in regions with distinct seasons, such as Europe and North America. Companies that supply bird feeding products can benefit by stocking seasonal items that attract specific hummingbird species during their migration periods. However, this approach requires careful inventory management to ensure that the right products are available at the right times.

How Does Temperature Influence Nectar Change Frequency?

Temperature-based change dictates how often nectar should be refreshed, with warmer climates necessitating more frequent changes to prevent spoilage. B2B buyers in warmer regions, such as parts of Africa and South America, must consider this factor when stocking products. Retailers can capitalize on this need by offering educational resources on nectar management, ensuring that customers understand the importance of freshness for bird health. While this approach ensures optimal feeding conditions, it may also require additional labor for maintenance.

What Are the Implications of Different Feeder Variations?

The type of feeder variation refers to the different designs and functionalities of hummingbird feeders, which can dictate maintenance needs. Suppliers of specialized feeders can offer tailored solutions that meet the unique feeding behaviors of various hummingbird species. However, this complexity can lead to challenges in inventory management, as retailers must stock a diverse range of products to cater to different customer needs. Understanding the nuances of feeder design can enhance customer satisfaction and loyalty.

Why Is Nectar Composition Change Important?

Nectar composition change involves adjusting the sugar-water ratio to mimic the natural sweetness of flowers that hummingbirds rely on. This practice is particularly relevant for B2B suppliers of nectar products, as it allows them to provide high-quality, specialized offerings that attract more birds. Educating consumers about the importance of proper nectar ratios can lead to increased sales, although it may require additional marketing efforts to convey this information effectively.

How Does Maintenance and Cleaning Cycle Affect Retailers?

Establishing a maintenance and cleaning cycle is crucial for ensuring the health of hummingbirds and the longevity of feeders. Retailers can leverage this need by offering cleaning products and guides for proper feeder upkeep. While this can enhance customer loyalty and repeat business, it may also deter some buyers who perceive regular maintenance as a burden. Providing easy-to-use cleaning solutions can mitigate this concern and promote a healthier feeding environment for birds.

Key Industrial Applications of when to change hummingbird feeder

| Industry/Sector | Specific Application of when to change hummingbird feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Ornithology Research | Monitoring nectar freshness for field studies | Ensures accurate data collection on hummingbird behavior | Quality control of nectar ingredients and feeder materials |

| Eco-Tourism | Maintaining feeders in wildlife observation areas | Enhances visitor experience and increases wildlife sightings | Sustainable feeder design and easy maintenance solutions |

| Agriculture | Pollinator support through managed habitats | Promotes biodiversity and crop pollination | Availability of eco-friendly nectar and feeder options |

| Retail and E-commerce | Inventory management for hummingbird feeder products | Improves customer satisfaction and repeat purchases | Supplier reliability and product variety |

| Landscaping Services | Installation of feeders in garden designs | Attracts pollinators, enhancing landscape value | Durable feeder materials suitable for various climates |

How Can Ornithology Research Benefit from Knowing When to Change Hummingbird Feeders?

In ornithology research, maintaining the freshness of nectar is crucial for accurate behavioral studies. Researchers must change the nectar every 2 to 4 days, especially in humid climates, to prevent spoilage that can skew data. This requirement necessitates sourcing high-quality feeder designs that allow for easy cleaning and nectar replacement. For international buyers, ensuring the availability of reliable nectar components and feeder materials is vital for supporting ongoing research initiatives.

What Role Does Eco-Tourism Play in Maintaining Hummingbird Feeders?

In eco-tourism, hummingbird feeders are essential for attracting wildlife, enhancing visitor experiences, and increasing the likelihood of bird sightings. By changing the nectar frequently, operators can ensure that feeders remain appealing to these birds. This not only boosts visitor satisfaction but also encourages repeat business. Tour operators should consider sourcing sustainable feeder designs that are easy to maintain and clean, thus supporting environmental stewardship while providing a unique tourist experience.

How Does Agriculture Benefit from Managed Hummingbird Habitats?

Agricultural sectors can significantly benefit from the introduction of hummingbird feeders in managed habitats. By understanding when to change the nectar, farmers can promote biodiversity and enhance pollination rates for crops. Regular nectar changes help to attract these vital pollinators, which can lead to increased yields. Buyers in this sector should focus on eco-friendly nectar options and durable feeders that can withstand various environmental conditions, particularly in regions like South America and Africa.

Why is Inventory Management Important for Retail and E-commerce?

For retailers and e-commerce businesses specializing in bird feeders, understanding the frequency of nectar changes is critical for inventory management. By ensuring that products are stocked with clear guidance on maintenance, businesses can enhance customer satisfaction and foster loyalty. Key sourcing considerations include partnering with reliable suppliers who offer a variety of feeder designs and nectar options, ensuring that customers have access to high-quality products that meet their needs.

How Can Landscaping Services Leverage Hummingbird Feeders?

Landscaping services can leverage the installation of hummingbird feeders to create visually appealing and ecologically beneficial designs. By regularly changing the nectar, landscapers can attract pollinators, adding value to their projects. This practice not only enhances the aesthetic appeal but also supports local ecosystems. Buyers in this sector should prioritize sourcing durable feeder materials that are effective in diverse climates, particularly in regions with varying weather conditions across Europe and the Middle East.

3 Common User Pain Points for ‘when to change hummingbird feeder’ & Their Solutions

Scenario 1: The Challenge of Nectar Spoilage in Warm Climates

The Problem: B2B buyers, especially those operating in warm climates such as parts of Africa or South America, often face the challenge of nectar spoilage. The high temperatures can lead to rapid fermentation, mold growth, and a decline in nectar quality, which can deter hummingbirds from visiting feeders. This not only affects bird populations but also the buyers’ ability to provide a reliable feeding source, which is crucial for businesses focused on wildlife conservation or bird-watching tourism.

The Solution: To address this issue, it is vital to establish a regular nectar replacement schedule. B2B buyers should implement a protocol of changing the nectar every 1-2 days during hot weather. Investing in high-quality, easy-to-clean feeders can facilitate this process, as they often come with features that minimize residue and mold buildup. Additionally, sourcing commercial nectar solutions that are specifically designed for high-temperature environments can help maintain quality. Educating staff on the importance of nectar freshness and establishing reminders or automated systems for nectar change can ensure that the feeders remain appealing to hummingbirds, thus enhancing the overall customer experience and supporting local ecosystems.

Scenario 2: Attracting Hummingbirds in Competitive Markets

The Problem: In regions where hummingbird feeders are prevalent, such as Europe and parts of the Middle East, businesses often struggle to attract these birds to their feeders due to competition from neighboring feeders. If the nectar is not changed regularly, it can spoil, leading to a decrease in hummingbird visits. This can negatively impact businesses that rely on birdwatching as a revenue stream, as fewer birds mean fewer tourists and less engagement with local wildlife.

The Solution: To stand out in a competitive market, B2B buyers should not only focus on regular nectar changes but also on the feeder’s strategic placement and cleanliness. It’s recommended to change the nectar every 3-4 days during cooler weather but more frequently during warmer periods. Additionally, employing unique feeder designs or colors can attract more hummingbirds. Utilizing technology, such as smart feeders that notify when nectar levels are low or when it needs changing, can streamline maintenance efforts. This proactive approach not only boosts hummingbird traffic but also enhances the experience for birdwatchers, providing a competitive edge.

Scenario 3: Managing Pests Around Hummingbird Feeders

The Problem: Pests, such as bees and wasps, can be a significant issue for B2B buyers who maintain hummingbird feeders. These insects are attracted to the nectar and can drive hummingbirds away, leading to a decline in feeder use. This is particularly problematic for businesses that rely on hummingbird traffic for educational tours or wildlife photography, as the presence of pests can deter customers and diminish the enjoyment of the experience.

The Solution: Effective pest management starts with regular nectar changes, ideally every 1-2 days in warm weather, to prevent spoilage and reduce attractants for pests. Buyers can also consider using bee guards or specialized feeders designed to minimize pest access while allowing hummingbirds to feed comfortably. Educating staff about proper feeder placement—keeping them away from yellow flowers and other attractants—can further mitigate pest problems. Additionally, integrating a pest control strategy, such as using natural deterrents like peppermint oil around the feeder area, can help keep bees at bay. By maintaining a clean feeding environment and implementing these strategies, businesses can ensure that hummingbirds remain the primary visitors to their feeders, enhancing customer satisfaction and promoting wildlife conservation.

Strategic Material Selection Guide for when to change hummingbird feeder

What Are the Key Materials for Hummingbird Feeders?

When selecting materials for hummingbird feeders, it is essential to consider properties that influence performance, durability, and safety. Here, we analyze four common materials used in the construction of hummingbird feeders: plastic, glass, metal, and silicone.

How Does Plastic Perform in Hummingbird Feeders?

Plastic is a widely used material for hummingbird feeders due to its lightweight nature and versatility. Key properties include resistance to corrosion and ease of molding into various shapes. However, plastics can degrade under prolonged exposure to sunlight and extreme temperatures, which may lead to brittleness over time.

Pros: Plastic feeders are generally affordable and available in various designs. They are easy to clean and maintain, making them suitable for frequent nectar changes.

Cons: The primary drawback is their susceptibility to UV degradation and potential leaching of harmful chemicals if not made from food-safe materials.

Illustrative image related to when to change hummingbird feeder

For international buyers, compliance with safety standards such as ASTM for plastics is crucial, especially in regions with strict regulations like Europe.

What Advantages Do Glass Feeders Offer?

Glass feeders are known for their aesthetic appeal and durability. They are resistant to weather elements and do not degrade as quickly as plastic. Key properties include excellent temperature resistance and a non-porous surface that minimizes bacterial growth.

Pros: Glass feeders maintain nectar freshness longer and are easier to clean, which is vital for the health of the hummingbirds. They also provide a premium look that appeals to consumers.

Cons: The main limitation is their weight, which can make them less portable. Additionally, glass can break easily if dropped.

For B2B buyers in markets like South America and Africa, ensuring that glass products meet safety standards is essential, particularly in regions where glass breakage can pose a risk.

Illustrative image related to when to change hummingbird feeder

How Do Metal Feeders Perform in Terms of Durability?

Metal feeders, often made of aluminum or stainless steel, offer exceptional durability and resistance to corrosion. Key properties include high tensile strength and the ability to withstand various weather conditions without degrading.

Pros: Metal feeders are long-lasting and often come with protective coatings that enhance their lifespan. They also provide a unique aesthetic that can attract higher-end consumers.

Cons: The primary drawback is the cost, as metal feeders tend to be more expensive than plastic or glass options. They can also heat up quickly in direct sunlight, potentially harming the nectar.

For international buyers, compliance with standards like DIN in Germany or JIS in Japan is crucial to ensure product quality and safety.

What Role Does Silicone Play in Hummingbird Feeder Design?

Silicone is increasingly being used in hummingbird feeder designs, particularly for seals and gaskets. Its key properties include flexibility, temperature resistance, and excellent adhesion capabilities.

Pros: Silicone is durable and can withstand a wide range of temperatures, making it suitable for various climates. It is also easy to clean and does not leach harmful substances.

Cons: However, silicone components may not be as readily available in all regions, and sourcing high-quality silicone can be a challenge.

For B2B buyers, ensuring that silicone materials meet international standards for food safety is critical, especially in markets that prioritize eco-friendly products.

Summary Table of Material Selection for Hummingbird Feeders

| Material | Typical Use Case for when to change hummingbird feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Lightweight feeders for casual use | Affordable and versatile | Susceptible to UV degradation | Low |

| Glass | Premium feeders for aesthetic appeal | Maintains nectar freshness longer | Breakable and heavier | High |

| Metal | Durable feeders for long-term use | Exceptional durability and weather resistance | Higher cost and heat retention | Med |

| Silicone | Seals and gaskets in feeder designs | Flexible and temperature resistant | Sourcing challenges in some regions | Med |

This detailed analysis provides B2B buyers with actionable insights into material selection for hummingbird feeders, taking into account performance, costs, and international compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for when to change hummingbird feeder

What Are the Key Stages in the Manufacturing Process for Hummingbird Feeders?

The manufacturing of hummingbird feeders involves several critical stages, each designed to ensure that the final product is safe, effective, and appealing to both birds and consumers. Understanding these stages can help B2B buyers make informed decisions when sourcing these products.

1. Material Preparation: What Materials Are Used in Hummingbird Feeder Production?

The first step in the manufacturing process is material preparation. Hummingbird feeders are typically made from a variety of materials, including glass, plastic, and metal. Each material offers distinct advantages:

- Glass: Durable and easy to clean, glass feeders are often favored for their aesthetic appeal.

- Plastic: Lightweight and less breakable, plastic feeders are popular for outdoor use but must be UV-resistant to prevent degradation from sunlight.

- Metal: Often used in components like hanging hooks, metal parts provide additional durability.

During this stage, manufacturers must ensure that all materials meet safety standards, particularly for food contact.

2. Forming: How Are Hummingbird Feeders Shaped and Constructed?

Once materials are prepared, the next phase is forming. This involves shaping the materials into the components of the feeder. Key techniques include:

- Injection Molding: Commonly used for plastic parts, this process allows for the creation of complex shapes and designs, including feeding ports and nectar reservoirs.

- Blowing: Glass feeders often undergo a blowing process to form their shapes, requiring skilled artisans to ensure quality.

- Stamping and Cutting: Metal components are typically stamped or cut to size, ensuring they fit together seamlessly.

Precision during this stage is critical, as any inconsistencies can lead to leaks or difficulty in cleaning.

3. Assembly: How Are Hummingbird Feeders Put Together?

After individual components are formed, they are assembled into the final product. This process may involve:

Illustrative image related to when to change hummingbird feeder

- Adhesives and Fasteners: Depending on the design, manufacturers may use adhesives for glass and plastic parts or screws for metal components.

- Quality Checks: As feeders are assembled, workers conduct preliminary quality checks to identify any defects before the final product is completed.

This stage is vital, as improper assembly can affect the feeder’s functionality and safety.

4. Finishing: What Final Touches Are Applied to Hummingbird Feeders?

The finishing stage involves applying any final touches to the feeders. This may include:

- Surface Treatments: For metal components, manufacturers may apply coatings to prevent rust and corrosion.

- Labeling and Packaging: Clear labeling is essential for informing consumers about proper use and care. Packaging must also be designed to protect the product during transportation.

At this point, feeders undergo a final inspection to ensure they meet aesthetic and functional standards.

What Quality Assurance Practices Are Essential in Hummingbird Feeder Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, especially in meeting international standards and ensuring customer satisfaction. B2B buyers should be aware of the QA practices that manufacturers should implement.

Relevant International Standards: Which Standards Should B2B Buyers Look For?

Manufacturers of hummingbird feeders are often required to comply with international quality standards. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality.

- CE Marking: In Europe, CE marking indicates that the product meets safety and health requirements.

- API Standards: For components that may interact with food, adherence to American Petroleum Institute (API) standards can be essential.

These certifications not only enhance product credibility but also ensure compliance with regional regulations.

QC Checkpoints: What Are the Key Quality Control Checkpoints?

Quality control checkpoints are critical for maintaining high standards throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help catch defects early.

- Final Quality Control (FQC): A comprehensive inspection of the finished product ensures it meets all quality standards before shipping.

B2B buyers should inquire about a manufacturer’s QC processes to ensure that they can trust the quality of the products they purchase.

What Testing Methods Are Commonly Used in Hummingbird Feeder Quality Assurance?

Manufacturers employ various testing methods to ensure that hummingbird feeders are safe and functional. Common testing methods include:

- Leak Testing: Ensures that feeders do not leak nectar, which can attract unwanted pests.

- Durability Testing: Assess the feeder’s ability to withstand environmental conditions, such as UV exposure and temperature fluctuations.

- Food Safety Testing: Verifies that materials used are safe for birds and do not leach harmful substances.

These tests provide B2B buyers with confidence in the product’s safety and longevity.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that manufacturers adhere to quality standards, B2B buyers should consider the following verification methods:

- Supplier Audits: Conducting on-site audits can provide insight into the manufacturer’s processes and adherence to quality standards.

- Quality Reports: Requesting detailed quality assurance reports can help buyers understand the manufacturer’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of a manufacturer’s quality control practices.

By taking these steps, B2B buyers can mitigate risks associated with sourcing hummingbird feeders.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific QC and certification nuances:

- Regional Compliance: Different regions may have unique regulatory requirements for bird feeders. Understanding these requirements is crucial for market entry.

- Cultural Preferences: Certain materials or designs may be more acceptable in specific cultures. Manufacturers should be aware of these preferences to cater to local markets effectively.

- Logistical Considerations: International shipping can affect product quality. Manufacturers must ensure that products are packaged securely to prevent damage during transit.

By understanding these nuances, B2B buyers can navigate the complexities of international sourcing more effectively.

In conclusion, a detailed understanding of the manufacturing processes and quality assurance practices for hummingbird feeders can empower B2B buyers to make informed decisions. By prioritizing quality, compliance, and supplier verification, businesses can ensure they source reliable products that meet customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘when to change hummingbird feeder’

To ensure the optimal care for hummingbirds and maintain the quality of nectar in feeders, it’s essential for B2B buyers to understand the appropriate timing for changing hummingbird feeders. This guide provides actionable steps to help organizations source and implement effective hummingbird feeder management practices.

1. Assess Environmental Conditions

Understanding the local climate is crucial in determining how often to change nectar. Warmer temperatures and humidity levels can accelerate spoilage, necessitating more frequent changes.

– Key Factors: Monitor temperature and humidity; higher temperatures may require changing nectar every 1-2 days.

2. Establish Nectar Change Frequency

Set a clear schedule for changing nectar based on seasonal changes and local weather patterns. Generally, nectar should be replaced every 2-4 days, but in warmer climates, this may need to be adjusted.

– Best Practices: Use a calendar or reminder system to track changes; ensure that all employees involved in feeder maintenance are informed of the schedule.

3. Implement a Cleaning Protocol

Regular cleaning of feeders is essential to prevent mold and bacteria growth. Establish a standard operating procedure for cleaning feeders before refilling them with fresh nectar.

– Cleaning Steps: Use hot water and a brush; avoid harsh chemicals that may harm birds. Rinse thoroughly to ensure no residue remains.

4. Monitor Bird Activity

Observe the frequency and behavior of hummingbirds visiting the feeders. If there’s a noticeable decrease in visits, it may indicate that nectar is spoiled or feeders are not being maintained properly.

– Action Items: Conduct daily checks during peak feeding times (early morning and late afternoon); adjust nectar changes based on bird activity.

5. Source Quality Nectar Ingredients

When preparing nectar, ensure that the ingredients used are of high quality. Avoid commercial nectars with artificial colors or additives, opting instead for a homemade mix of sugar and water.

– Recipe Guidelines: Use a 4:1 water-to-sugar ratio; boil the water to eliminate chlorine and allow it to cool before mixing.

Illustrative image related to when to change hummingbird feeder

6. Evaluate Feeder Design

Select feeders designed to minimize bee and wasp attraction, which can deter hummingbirds. Assess feeder ports and colors, ensuring they are optimized for hummingbird use.

– Design Considerations: Look for feeders with bee guards or those that use red hues rather than yellow to avoid attracting unwanted insects.

7. Train Staff on Best Practices

Educate employees involved in hummingbird feeder maintenance about the importance of these practices. Regular training sessions can help ensure that everyone understands their role in maintaining feeder quality.

– Training Components: Include information on nectar preparation, feeder cleaning, and monitoring bird activity to foster a knowledgeable team.

By following this checklist, B2B buyers can effectively manage hummingbird feeders, ensuring a safe and inviting environment for these birds while also optimizing the feeder’s functionality and maintenance practices.

Illustrative image related to when to change hummingbird feeder

Comprehensive Cost and Pricing Analysis for when to change hummingbird feeder Sourcing

What Are the Key Cost Components in Hummingbird Feeder Sourcing?

When evaluating the cost structure for sourcing hummingbird feeders, several components must be considered to ensure a comprehensive understanding. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly affects costs. Common materials for feeders include glass, plastic, and metal. Glass feeders, while more aesthetically appealing, are often more expensive due to their fragility and manufacturing complexity. In contrast, plastic feeders are lightweight and durable but may not convey the same market value.

-

Labor: Labor costs vary by region and the complexity of production processes. Automated manufacturing can reduce labor costs but may require higher initial investments in machinery. In regions with lower labor costs, such as parts of Africa and South America, manufacturers may achieve significant savings.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. A well-optimized factory setup can reduce overhead costs, making it crucial for manufacturers to evaluate their operational efficiencies continually.

-

Tooling: Initial setup costs for molds and tooling can be substantial, particularly for custom designs. Buyers should consider these costs when negotiating prices, especially if they anticipate high volumes.

-

Controlo de qualidade: Ensuring product quality through rigorous QC processes is essential to prevent defects that could harm brand reputation. This may involve additional costs but is often justified by the reduction in returns and customer dissatisfaction.

-

Logistics: Shipping costs can vary significantly based on distance, mode of transport, and the chosen Incoterms. For international buyers, understanding logistics costs is critical, as these can dramatically impact the total landed cost of the product.

-

Margin: Suppliers typically add a profit margin to cover risks and ensure sustainability. This margin can be influenced by market demand, competition, and the overall economic environment.

How Do Price Influencers Affect Hummingbird Feeders?

Several factors influence pricing in the hummingbird feeder market, impacting both suppliers and buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts. Buyers should negotiate volume pricing, especially if they plan to resell feeders or integrate them into larger product offerings.

-

Specifications and Customization: Custom designs or features can increase costs. Buyers seeking unique feeders should be prepared for higher prices due to increased material and labor demands.

-

Quality Certifications: Products that meet specific quality standards or certifications may command higher prices. Buyers should assess whether these certifications are necessary for their target markets.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions. The chosen terms dictate responsibilities for shipping, insurance, and customs clearance, impacting the overall cost structure.

What Are the Best Buyer Tips for Cost Efficiency?

To maximize cost efficiency when sourcing hummingbird feeders, buyers should consider the following strategies:

Illustrative image related to when to change hummingbird feeder

-

Negotiate Effectively: Engage suppliers in discussions about pricing, particularly regarding bulk orders or long-term contracts. Building strong relationships can lead to better terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the initial purchase price but also ongoing costs such as maintenance, warranty, and potential returns. A slightly higher upfront cost may lead to lower TCO if the product is of higher quality.

-

Research Regional Variations: Understand pricing nuances across different regions. For instance, suppliers in Europe may have different pricing structures compared to those in South America, influenced by local market conditions and regulations.

-

Assess Shipping Options: Explore various shipping methods and routes. Choosing a cost-effective logistics partner can significantly reduce overall expenses, especially for international shipments.

-

Monitor Market Trends: Stay informed about market changes, such as shifts in material costs or consumer preferences. This knowledge can provide leverage in negotiations and strategic planning.

Conclusion

By understanding the cost components and price influencers in the hummingbird feeder market, international B2B buyers can make informed sourcing decisions. Adopting strategic negotiation techniques and evaluating total costs will enhance profitability and competitiveness in this niche market.

Alternatives Analysis: Comparing when to change hummingbird feeder With Other Solutions

Exploring Alternatives to Changing Hummingbird Feeders

In the realm of bird care, particularly when it comes to maintaining hummingbird feeders, the method of changing nectar is crucial for the health of the birds. However, there are alternative solutions and technologies that can offer similar benefits while potentially enhancing efficiency. This section compares the traditional approach of changing hummingbird feeders against alternative methods and technologies that serve the same purpose.

Comparison Table

| Comparison Aspect | When To Change Hummingbird Feeder | Automatic Nectar Dispenser | Solar-Powered Nectar Feeder |

|---|---|---|---|

| Performance | High; prevents spoilage and attracts birds effectively | Moderate; requires reliable power source | High; maintains ideal temperature for nectar |

| Cost | Low; primarily involves sugar and water | Moderate to high; initial investment for technology | Moderate; includes solar tech and materials |

| Ease of Implementation | Simple; requires basic knowledge of nectar preparation | Moderate; installation and calibration needed | Moderate; setup of solar components required |

| Maintenance | Regular; needs frequent cleaning and nectar changes | Low; minimal maintenance once set up | Moderate; requires cleaning and solar panel upkeep |

| Best Use Case | General use for backyard birders | Commercial setups or high-traffic areas | Eco-friendly solutions in sunny regions |

Detailed Breakdown of Alternatives

Automatic Nectar Dispenser

Automatic nectar dispensers are designed to regulate the flow of nectar and can be programmed to dispense fresh nectar at set intervals. The primary advantage is the reduction in manual labor required for changing nectar. However, these devices often rely on electrical power, which may not be available in all locations, especially in rural or remote areas. Additionally, the initial investment can be significant, making this option more suitable for businesses or organizations with higher budgets.

Solar-Powered Nectar Feeder

Solar-powered feeders use renewable energy to maintain optimal nectar conditions, preventing spoilage due to temperature fluctuations. This technology is particularly beneficial in regions with abundant sunlight, making it an eco-friendly option. The pros include lower operational costs over time and a sustainable approach to bird feeding. However, the need for regular cleaning and maintenance of both the feeder and solar components can be a drawback, especially in environments with high dust or debris.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate method or technology for managing hummingbird feeders depends on various factors, including the specific needs of the target audience, budget constraints, and environmental conditions. For businesses focused on sustainability and efficiency, solar-powered feeders may offer long-term benefits despite higher upfront costs. Conversely, organizations looking for straightforward, low-cost solutions may prefer traditional methods of changing nectar regularly. Ultimately, understanding the unique context of the operation will guide buyers in making informed decisions that align with their objectives in bird care and environmental stewardship.

Essential Technical Properties and Trade Terminology for when to change hummingbird feeder

What Are the Critical Specifications for Changing Hummingbird Feeders?

Understanding the technical properties of hummingbird feeders is essential for businesses involved in the production, distribution, or retail of these products. Below are several key specifications that can impact the effectiveness and longevity of hummingbird feeders:

-

Material Grade

– Definition: The type of material used to manufacture the feeder, such as glass, plastic, or metal.

– Importance: Higher-grade materials can withstand environmental factors better, reducing wear and tear and extending product life. For instance, UV-resistant plastics are crucial in sunny climates to prevent fading and cracking. -

Temperature Tolerance

– Definition: The range of temperatures the feeder can effectively handle without degrading.

– Importance: In regions with extreme temperatures, feeders must maintain structural integrity and functionality. A feeder that can withstand high temperatures will not warp, ensuring it remains usable and safe for hummingbirds. -

Nectar Capacity

– Definition: The volume of nectar the feeder can hold, usually measured in ounces or milliliters.

– Importance: Businesses must match feeder capacity with local hummingbird populations and feeding habits. Larger feeders may be beneficial in areas with high traffic, reducing the frequency of nectar changes. -

Cleaning Ease

– Definition: The design features that facilitate the cleaning process, such as removable parts or wide openings.

– Importance: Frequent cleaning is essential to prevent mold and spoilage. Feeders that are easy to clean encourage regular maintenance, which is critical for attracting hummingbirds. -

Feeding Port Design

– Definition: The configuration and size of the feeding ports where hummingbirds access nectar.

– Importance: Properly designed ports can prevent bees and other insects from accessing the nectar, which is vital for maintaining a hummingbird-friendly environment. Additionally, the right size ensures that only hummingbirds can feed efficiently. -

Durability and Weather Resistance

– Definition: The ability of the feeder to resist damage from rain, snow, and UV exposure.

– Importance: In regions with harsh weather, durable feeders minimize replacement costs and enhance customer satisfaction. Weather-resistant feeders are a selling point in markets where feeder longevity is critical.

What Are the Common Trade Terms Associated with Hummingbird Feeders?

Familiarity with industry jargon is crucial for effective communication between suppliers and buyers. Here are several common terms relevant to the hummingbird feeder market:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Buyers looking for unique designs or custom feeders often engage with OEMs to create products tailored to specific market needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is essential for B2B buyers to manage inventory and cash flow effectively. Low MOQs can facilitate trial orders for new products. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and other details for specific products.

– Relevance: An RFQ can help buyers compare prices and terms across multiple suppliers, ensuring competitive procurement. -

Incoterms (International Commercial Terms)

– Definition: Standardized trade terms that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms is vital for managing shipping costs and responsibilities, especially when sourcing feeders from international suppliers. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the goods.

– Relevance: Understanding lead times is critical for inventory planning and ensuring timely supply to meet market demand. -

Warranty Period

– Definition: The duration during which a product is guaranteed against defects.

– Relevance: A longer warranty period can enhance customer confidence in the product’s quality and durability, influencing purchasing decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding hummingbird feeders, ensuring they meet both market demands and operational efficiencies.

Navigating Market Dynamics and Sourcing Trends in the when to change hummingbird feeder Sector

What Are the Key Market Dynamics Influencing Hummingbird Feeder Maintenance?

The hummingbird feeder market is experiencing transformative dynamics driven by consumer preferences for sustainability and ethical sourcing. As environmental awareness grows, international buyers—particularly in regions like Africa, South America, the Middle East, and Europe—are increasingly seeking products that align with eco-friendly practices. This shift is influenced by a broader global trend towards sustainability, where consumers are more inclined to support brands that demonstrate a commitment to environmental stewardship.

Emerging technologies are playing a crucial role in this sector. Innovations in feeder design, such as self-cleaning features or materials that enhance durability and ease of maintenance, are gaining traction. These advancements not only improve user experience but also extend the product lifecycle, reducing waste. Moreover, digital platforms facilitate easier sourcing and distribution, allowing B2B buyers to access a broader range of suppliers and product specifications, enhancing their ability to meet consumer demands efficiently.

As the market evolves, understanding regional preferences becomes paramount. For instance, buyers in Brazil may prioritize products that withstand humid climates, while those in Germany might focus on energy-efficient manufacturing practices. This localized approach can significantly influence procurement strategies and product offerings, ensuring that B2B buyers remain competitive in a rapidly changing marketplace.

How Can Sustainability and Ethical Sourcing Impact Hummingbird Feeder Supply Chains?

Sustainability is no longer a buzzword; it has become a critical component of business strategy for B2B buyers in the hummingbird feeder sector. The environmental impact of production processes, from raw material sourcing to manufacturing practices, is under scrutiny. Buyers are increasingly looking for suppliers who can demonstrate a commitment to sustainable practices, such as using recycled materials or low-impact manufacturing techniques.

Ethical supply chains are essential in fostering consumer trust. Buyers should prioritize suppliers who can provide transparency regarding their sourcing practices, labor conditions, and environmental policies. Certifications such as Fair Trade or Eco-Label can serve as indicators of a supplier’s commitment to ethical standards. Additionally, the use of green materials in the production of hummingbird feeders—like biodegradable plastics or sustainably sourced wood—can enhance brand reputation and appeal to environmentally conscious consumers.

Investing in sustainable practices not only aligns with consumer expectations but also mitigates risks associated with regulatory compliance and reputational damage. As global markets continue to emphasize sustainability, B2B buyers in the hummingbird feeder sector must adapt their sourcing strategies to ensure they remain relevant and responsible.

What Is the Historical Context of Hummingbird Feeders?

The evolution of hummingbird feeders can be traced back to the late 19th century when bird enthusiasts sought ways to attract these vibrant creatures to their gardens. Originally made from simple glass and metal designs, these feeders have transformed significantly over the decades. The introduction of new materials and technologies has led to the development of more efficient and user-friendly feeders, incorporating features that make maintenance easier, such as built-in cleaning mechanisms and bee guards.

As awareness of environmental issues has grown, the market has shifted towards more sustainable designs, reflecting broader consumer trends. Today, B2B buyers are not only looking for functional products but also those that align with sustainable practices and ethical sourcing, marking a significant evolution in the hummingbird feeder market that continues to shape sourcing strategies and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of when to change hummingbird feeder

-

1. How often should I change the nectar in hummingbird feeders?

The frequency of changing nectar largely depends on environmental conditions. In warmer or humid climates, it’s advisable to change the nectar every 1-2 days to prevent spoilage. In cooler conditions, nectar can remain fresh for up to 4 days. Regularly changing the nectar is crucial for maintaining the health of the hummingbirds and encouraging them to visit your feeders consistently. For businesses, ensuring fresh nectar can also enhance customer satisfaction and promote repeat purchases. -

2. What are the signs that nectar has spoiled in a hummingbird feeder?

Spoiled nectar can exhibit a cloudy appearance, a foul odor, or the presence of mold. If you notice any of these signs, it’s essential to replace the nectar immediately. Spoiled nectar can deter hummingbirds and may even harm their health. Regular inspection and maintenance of feeders are vital to ensure that your product offerings meet high-quality standards, which can reflect positively on your brand. -

3. How can I customize hummingbird feeders for my market?

Customization options for hummingbird feeders may include size, color, and design features like feeding ports and materials. Engage with your suppliers to explore available customization options that align with local preferences and environmental conditions. Offering localized designs can enhance market appeal and cater to specific customer demands, ultimately driving sales in your target regions. -

4. What is the minimum order quantity (MOQ) for hummingbird feeders?

Minimum order quantities can vary significantly among manufacturers and suppliers. Typically, MOQs range from 100 to 1,000 units, depending on the product specifications and customization options. It’s crucial to discuss MOQs during the initial negotiation stages to ensure they align with your inventory needs and financial capabilities. Understanding MOQs can help optimize your supply chain and inventory management. -

5. How can I vet suppliers for hummingbird feeders effectively?

Vetting suppliers involves assessing their production capabilities, quality control processes, and past performance. Request samples to evaluate product quality, and check customer references or reviews to gauge reliability. Additionally, consider suppliers’ compliance with international trade regulations and sustainability practices, especially in regions like Europe where eco-friendly standards are crucial. A thorough vetting process can mitigate risks and ensure a reliable partnership. -

6. What payment terms are common in international trade for hummingbird feeders?

Payment terms can vary, but common practices include advance payment, letter of credit, and net 30 to net 90 days after delivery. It’s essential to negotiate terms that protect both parties, considering factors such as order size and supplier relationship. Establishing clear payment terms can help manage cash flow and build trust with your suppliers, facilitating smoother transactions. -

7. What logistics considerations should I keep in mind when sourcing hummingbird feeders?

Logistics considerations include shipping methods, costs, delivery times, and customs regulations. Evaluate the most efficient shipping options based on your target market to balance cost and speed. Additionally, ensure that your suppliers are familiar with international shipping practices to avoid delays and extra fees at customs. Having a robust logistics plan is essential for maintaining a reliable supply chain. -

8. How can I ensure quality assurance (QA) for hummingbird feeders?

Implementing a quality assurance process involves setting clear specifications for materials, design, and functionality. Work closely with your suppliers to establish quality benchmarks and consider third-party inspections before shipment. Regular audits and feedback loops can also help in maintaining product quality over time. A strong QA process not only ensures customer satisfaction but also enhances your reputation in the market.

Top 3 When To Change Hummingbird Feeder Manufacturers & Suppliers List

1. Facebook – Hummingbird Feeder

2. Perky-Pet – Hummingbird Nectar

Domain: perkypet.com

Registered: 1996 (29 years)

Introduction: Perky-Pet® Hummingbird Nectar: 100% sucrose formula, no artificial flavors or sweeteners. Available in various forms: Liquid Concentrate (64 oz bottle makes up to 256 oz of nectar) and Instant Powder (2 lb bag makes up to 192 oz of nectar). Easy to mix with water. Regular cleaning of feeders is essential to prevent spoilage and ensure hummingbird health.

3. Wildlife Rescue – Hummingbird Feeders

Domain: wildliferescue.ca

Registered: 2000 (25 years)

Introduction: Hummingbird feeders are essential for attracting native Rufous and Anna’s Hummingbirds. They should be taken down in September before migration to avoid altering feeding behaviors. Hummingbirds consume half their weight in sugar daily, requiring a nectar mixture of ¼ cup sugar to 1 cup water, served at room temperature. Feeders must be cleaned every day or every other day, especially in hot weathe…

Strategic Sourcing Conclusion and Outlook for when to change hummingbird feeder

As you navigate the complexities of sourcing hummingbird feeders and nectar, it’s vital to prioritize freshness and quality. The key takeaway is that maintaining a consistent schedule for changing nectar—ideally every 2 to 4 days, or more frequently in warmer climates—ensures that your products meet the expectations of end consumers. By emphasizing freshness, you not only enhance the attractiveness of your feeders but also build trust with your customer base, crucial for fostering long-term relationships in the B2B market.

Strategic sourcing is essential in this context, as it enables you to select suppliers who adhere to high-quality standards for both feeders and nectar. This consideration is especially important for international buyers in diverse markets such as Africa, South America, the Middle East, and Europe, where local preferences and climatic conditions can vary significantly.

Illustrative image related to when to change hummingbird feeder

Looking ahead, consider leveraging data analytics and market insights to refine your sourcing strategies further. By staying informed about trends and consumer behaviors, you can adapt quickly and effectively, ensuring your offerings remain competitive. Engage with suppliers who prioritize sustainability and innovation, setting your business apart in a rapidly evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.