Introduction: Navigating the Global Market for dog food auto dispenser

In the rapidly evolving pet care market, sourcing reliable dog food auto dispensers presents a significant challenge for B2B buyers seeking to meet the demands of pet owners globally. As the trend towards automation and convenience grows, businesses must navigate an array of options, from basic gravity feeders to sophisticated app-controlled devices equipped with RFID technology. This guide provides an in-depth exploration of the various types of dog food auto dispensers available in the market, their specific applications, and the advantages they offer in terms of efficiency and pet health.

By focusing on key considerations such as supplier vetting, pricing structures, and market trends, this comprehensive resource equips international buyers—especially those in Africa, South America, the Middle East, and Europe—with the insights needed to make informed purchasing decisions. Understanding the nuances of each product type, including their capacity, features, and maintenance requirements, will empower businesses to select dispensers that align with their operational goals and customer expectations.

Furthermore, as the demand for innovative pet care solutions continues to rise, this guide serves as a valuable tool for identifying reputable suppliers and ensuring quality assurance. With actionable strategies and expert advice, B2B buyers will be well-prepared to navigate the complexities of the global market for dog food auto dispensers, ultimately enhancing their product offerings and customer satisfaction.

Table Of Contents

- Top 6 Dog Food Auto Dispenser Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for dog food auto dispenser

- Understanding dog food auto dispenser Types and Variations

- Key Industrial Applications of dog food auto dispenser

- 3 Common User Pain Points for ‘dog food auto dispenser’ & Their Solutions

- Strategic Material Selection Guide for dog food auto dispenser

- In-depth Look: Manufacturing Processes and Quality Assurance for dog food auto dispenser

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘dog food auto dispenser’

- Comprehensive Cost and Pricing Analysis for dog food auto dispenser Sourcing

- Alternatives Analysis: Comparing dog food auto dispenser With Other Solutions

- Essential Technical Properties and Trade Terminology for dog food auto dispenser

- Navigating Market Dynamics and Sourcing Trends in the dog food auto dispenser Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dog food auto dispenser

- Strategic Sourcing Conclusion and Outlook for dog food auto dispenser

- Important Disclaimer & Terms of Use

Understanding dog food auto dispenser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Programmable Dry Feeders | Built-in timers for meal scheduling | Pet care facilities, kennels, retailers | Pros: Consistent feeding, portion control. Cons: Limited to dry food only. |

| Smart Automatic Feeders | Wi-Fi connectivity, app control, and monitoring | Veterinary clinics, pet boarding services | Pros: Remote monitoring, customizable feeding. Cons: Higher cost, requires tech setup. |

| Gravity Feeders | Simple design, gravity-operated for continuous feeding | Shelters, rescue organizations | Pros: Low maintenance, no power required. Cons: Less control over portion sizes. |

| Wet Food Dispensers | Refrigeration features for wet food preservation | High-end pet stores, specialty shops | Pros: Maintains freshness, suitable for picky eaters. Cons: More complex and expensive. |

| Multi-Pet Feeders | Dual or multiple food trays for simultaneous feeding | Multi-pet households, breeders | Pros: Efficient for multiple pets, reduces feeding time. Cons: Bulkier and may require more space. |

What are Programmable Dry Feeders and Their Benefits for B2B Buyers?

Programmable dry feeders are designed with built-in timers that allow pet owners to schedule meal times. This feature is particularly beneficial for businesses such as pet care facilities and kennels, where consistent feeding schedules are essential for maintaining the health and well-being of animals. B2B buyers should consider the durability and capacity of these feeders to ensure they meet the demands of their operations.

How Do Smart Automatic Feeders Enhance Pet Care Services?

Smart automatic feeders are equipped with Wi-Fi connectivity and app control, enabling remote monitoring and customizable feeding schedules. These feeders are ideal for veterinary clinics and pet boarding services, as they allow caregivers to manage feeding times and portions from anywhere. When purchasing, businesses should evaluate the compatibility of these devices with existing technology and the level of customer support provided by manufacturers.

Why Choose Gravity Feeders for Low-Maintenance Solutions?

Gravity feeders utilize a simple design that dispenses food as pets eat, making them an excellent choice for shelters and rescue organizations. These feeders require minimal maintenance and do not rely on electricity, making them suitable for varied environments. However, buyers should be aware that gravity feeders offer less control over portion sizes, which could lead to overfeeding if not monitored closely.

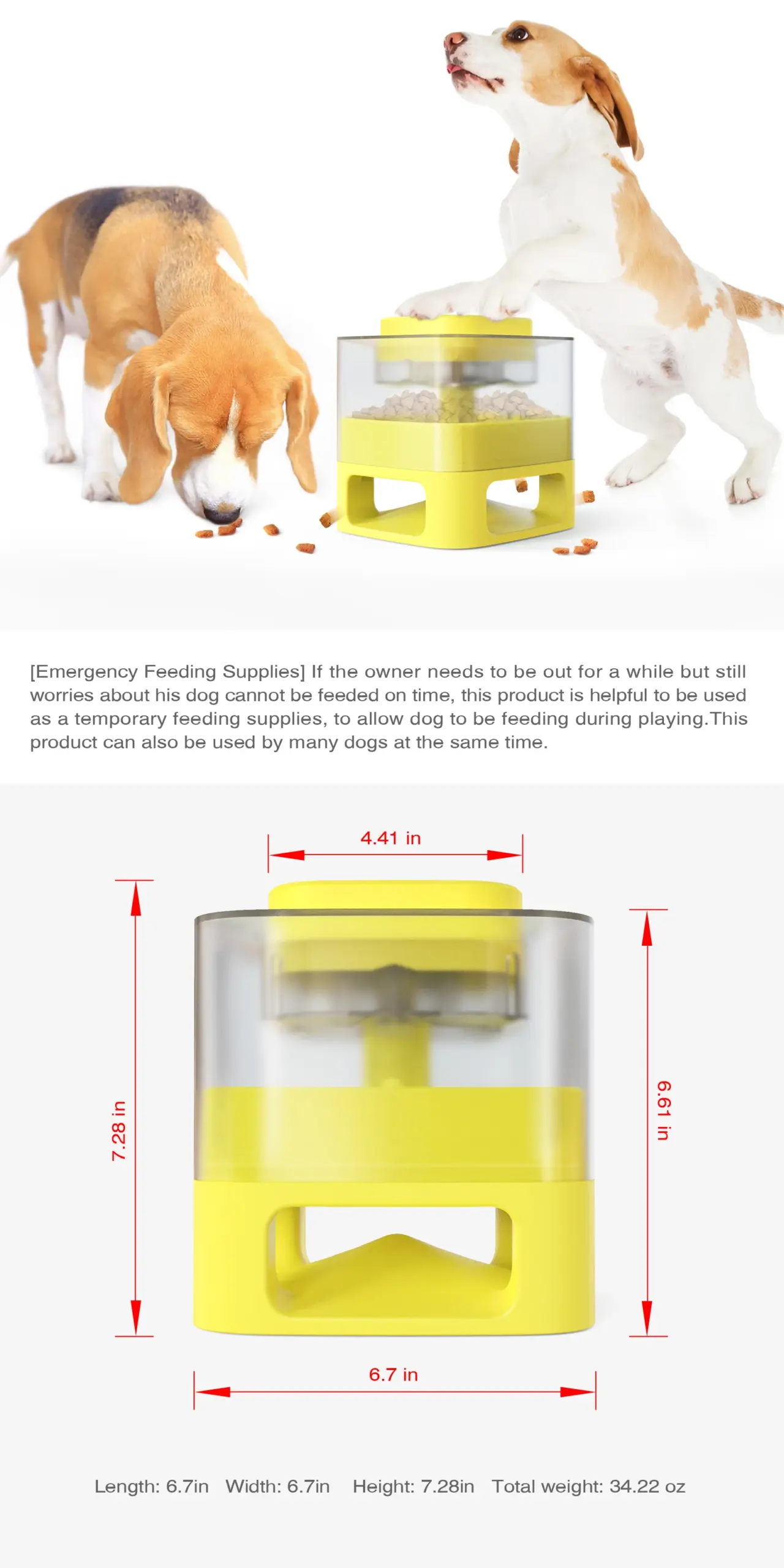

Illustrative image related to dog food auto dispenser

What are the Advantages of Wet Food Dispensers for Specialty Pet Stores?

Wet food dispensers often come with refrigeration features to preserve the freshness of wet food, catering to picky eaters. These dispensers are particularly suitable for high-end pet stores and specialty shops that focus on premium pet nutrition. B2B buyers should assess the complexity of these systems and their price points, ensuring they align with their target market’s preferences and budgets.

How Do Multi-Pet Feeders Optimize Feeding in Diverse Environments?

Multi-pet feeders feature dual or multiple food trays, allowing for simultaneous feeding of several pets. These feeders are beneficial for multi-pet households and breeders, as they save time and streamline the feeding process. Buyers should consider the feeder’s size and design to ensure it fits well in their intended space and meets the needs of their clientele.

Key Industrial Applications of dog food auto dispenser

| Industry/Sector | Specific Application of dog food auto dispenser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Care Services | Automated feeding in pet boarding facilities | Enhances operational efficiency and pet care quality | Reliability, capacity, ease of cleaning, and warranty |

| Animal Shelters | Feeding multiple dogs in shelter environments | Reduces labor costs and ensures consistent nutrition | Durability, programmable features, and maintenance support |

| Veterinary Clinics | Post-surgery feeding management | Facilitates timely feeding and recovery monitoring | FDA compliance, ease of use, and hygiene standards |

| Retail Pet Supply Stores | Demonstration units for customer engagement | Boosts sales through interactive product display | Product variety, stock levels, and price competitiveness |

| Dog Training Facilities | Scheduled feeding for training regimens | Supports behavioral training and weight management | Programmability, portion control, and user-friendly interfaces |

How Are Dog Food Auto Dispensers Used in Pet Care Services?

In pet care services, dog food auto dispensers are utilized to automate feeding schedules in boarding facilities. This technology not only ensures that pets receive their meals at the appropriate times but also alleviates the workload on staff. By providing consistent nutrition, facilities can enhance the overall health and well-being of the animals in their care, which is vital for maintaining a good reputation. Buyers in this sector should prioritize reliability and ease of cleaning, as these units will be used frequently and require regular maintenance.

What Role Do Dog Food Auto Dispensers Play in Animal Shelters?

Animal shelters employ dog food auto dispensers to streamline the feeding process for multiple dogs. This application minimizes labor costs and ensures that all animals receive the necessary nutrition without requiring constant staff supervision. The dispensers can be programmed to deliver specific portions, which is crucial for managing the diets of dogs with special needs. Buyers from shelters should focus on the durability of the dispensers and the availability of maintenance support, as these units will face heavy use.

How Are Dog Food Auto Dispensers Beneficial in Veterinary Clinics?

In veterinary clinics, dog food auto dispensers are particularly useful for managing post-surgery feeding. These dispensers allow for precise portion control, which is essential for monitoring recovery and ensuring that dogs receive the right amount of nutrients at the right times. This technology can aid in the overall recovery process by providing consistent feeding schedules. For international buyers, especially in regions with strict health regulations, it’s crucial to source dispensers that comply with FDA standards and are easy to sanitize.

Why Are Dog Food Auto Dispensers Important for Retail Pet Supply Stores?

Retail pet supply stores often utilize dog food auto dispensers as demonstration units to engage customers. By showcasing how these dispensers operate, stores can enhance the shopping experience and drive sales. Customers appreciate seeing the technology in action, which can lead to increased confidence in purchasing decisions. When sourcing these units, retailers should consider product variety and stock levels to meet customer demand, as well as competitive pricing to attract budget-conscious buyers.

How Do Dog Food Auto Dispensers Support Dog Training Facilities?

In dog training facilities, auto dispensers play a crucial role in maintaining scheduled feeding regimens that support training goals. By using programmable dispensers, trainers can manage the nutritional intake of dogs, which is essential for behavioral training and weight control. This ensures that each dog receives the right amount of food at the right times, thereby optimizing training outcomes. Buyers in this sector should prioritize features like programmability and user-friendly interfaces to facilitate ease of use during training sessions.

3 Common User Pain Points for ‘dog food auto dispenser’ & Their Solutions

Scenario 1: Managing Diverse Pet Diets Effectively

The Problem: In a multi-pet environment, such as a kennel or pet care facility, managing different dietary needs can become a complex challenge. B2B buyers often face the issue of ensuring that each pet receives the right amount and type of food at the appropriate times. Mismanagement can lead to health issues for pets, customer complaints, and ultimately loss of business. Additionally, the inability to monitor feeding schedules or portions can result in overfeeding or underfeeding, which directly impacts pet health and client satisfaction.

The Solution: To effectively manage diverse pet diets, B2B buyers should consider investing in automatic dog food dispensers that feature programmable settings and multiple food trays. Look for models that allow for customization of portion sizes and feeding times. For instance, dispensers with app integration provide real-time monitoring and control, enabling pet care managers to adjust feeding schedules remotely. Furthermore, sourcing dispensers with RFID recognition technology can ensure that each pet receives its specific diet without confusion. Implementing a system that categorizes pets based on their dietary needs and automating the feeding process can significantly streamline operations and enhance client trust.

Scenario 2: Ensuring Freshness and Quality of Food

The Problem: Many pet care businesses struggle with maintaining the freshness and quality of the food they serve. Automatic dispensers that do not adequately seal or preserve food can lead to stale or spoiled offerings, which can damage the reputation of the business. B2B buyers must ensure that they are providing pets with high-quality food, as pet owners are increasingly conscious about the nutritional value and freshness of their pets’ meals.

The Solution: When selecting an automatic dog food dispenser, prioritize models that feature vacuum-sealing technology or airtight compartments to preserve food freshness. B2B buyers should also consider dispensers that come equipped with temperature control features, ensuring that wet food remains at safe temperatures. Additionally, sourcing dispensers that allow for easy cleaning and maintenance will help in keeping the food storage areas hygienic. It is advisable to conduct regular checks on food quality and to educate staff on proper food storage practices to further mitigate risks associated with spoilage.

Scenario 3: Overcoming Operational Challenges in High-Demand Situations

The Problem: High-demand periods, such as holidays or local events, can overwhelm pet care facilities, leading to operational inefficiencies. During these times, B2B buyers may find it challenging to manage feeding schedules and maintain consistent service quality. The risk of human error increases, and the potential for customer dissatisfaction rises when staff is stretched thin.

Illustrative image related to dog food auto dispenser

The Solution: To combat the operational challenges during peak times, B2B buyers should invest in high-capacity automatic dog food dispensers that can hold larger quantities of food and dispense it efficiently. Opt for models that support multiple feeding schedules, allowing for batch feeding during busy hours. Implementing a centralized feeding management system that integrates with existing operational software can streamline processes, allowing for better planning and resource allocation. Training staff on how to utilize these dispensers effectively can further enhance service delivery, ensuring that pets are fed on time regardless of demand fluctuations. This proactive approach can lead to improved customer satisfaction and operational resilience.

Strategic Material Selection Guide for dog food auto dispenser

When selecting materials for dog food auto dispensers, it is essential to consider properties such as durability, cost-effectiveness, and compliance with international standards. The following analysis focuses on four common materials used in the manufacturing of these dispensers: plastic, stainless steel, aluminum, and glass. Each material has unique characteristics that can significantly influence product performance and market acceptance in various regions.

What Are the Key Properties of Plastic in Dog Food Auto Dispensers?

Plastic is a widely used material in dog food auto dispensers due to its lightweight nature and versatility. Common types include polyethylene and polypropylene, which offer good resistance to impact and moisture. Plastics can withstand temperatures up to 70°C, making them suitable for both dry and semi-moist food applications.

Pros and Cons: The primary advantage of plastic is its cost-effectiveness and ease of manufacturing, allowing for complex designs and colors. However, plastics can be prone to scratching and may not be as durable as metals, leading to potential long-term wear and tear.

Impact on Application: Plastic is compatible with a variety of dog food types but may absorb odors over time, which could affect food quality.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with food safety standards, such as FDA regulations in the U.S. or EFSA guidelines in Europe. In regions like Africa and South America, where regulations may vary, understanding local compliance is crucial.

How Does Stainless Steel Perform in Dog Food Auto Dispensers?

Stainless steel is favored for its durability and corrosion resistance, making it an ideal choice for high-end dispensers. It can withstand temperatures exceeding 200°C and is resistant to staining, rust, and corrosion.

Pros and Cons: The key advantage of stainless steel is its longevity and hygiene, as it is easy to clean and does not retain odors. However, the higher manufacturing costs can make these dispensers less accessible for budget-conscious consumers.

Impact on Application: Stainless steel is suitable for all types of dog food and is often preferred in regions with high humidity, as it does not degrade over time.

Considerations for International Buyers: Compliance with international standards such as ASTM for materials and finishes is essential. Buyers in the Middle East and Europe may prefer stainless steel for its aesthetic appeal and durability.

Illustrative image related to dog food auto dispenser

What Are the Benefits of Using Aluminum in Dog Food Auto Dispensers?

Aluminum is another lightweight and corrosion-resistant option, often used in combination with other materials. It offers a good balance between strength and weight, with temperature ratings similar to stainless steel.

Pros and Cons: The main advantage of aluminum is its lightweight nature, making it easy to transport and handle. However, it is less durable than stainless steel and can be prone to denting.

Impact on Application: Aluminum is suitable for dry food applications but may not be ideal for wet food due to potential corrosion over time.

Considerations for International Buyers: Buyers should check for compliance with local regulations regarding aluminum usage in food applications. In regions like Vietnam, where aluminum products are common, understanding local preferences can enhance market penetration.

Why Is Glass Considered for Dog Food Auto Dispensers?

Glass is less common but is sometimes used for its aesthetic appeal and inert properties. It does not react with food, ensuring that flavors remain pure.

Illustrative image related to dog food auto dispenser

Pros and Cons: The key advantage of glass is its non-porous nature, which prevents odor retention and is easy to clean. However, glass is heavy and can break easily, making it less practical for some applications.

Impact on Application: Glass is suitable for both dry and wet food but may not be ideal for outdoor or high-traffic environments.

Considerations for International Buyers: Compliance with safety regulations is crucial, especially in regions with stringent consumer safety laws. Buyers in Europe may appreciate the eco-friendly aspect of glass, while those in Africa may prefer more durable options.

Summary Table of Material Selection for Dog Food Auto Dispensers

| Material | Typical Use Case for dog food auto dispenser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Budget-friendly dispensers | Lightweight and versatile | Prone to scratching and wear | Low |

| Stainless Steel | Premium dispensers for durability | Long-lasting and hygienic | Higher manufacturing costs | High |

| Aluminum | Lightweight dispensers | Good strength-to-weight ratio | Less durable than stainless steel | Medium |

| Glass | Aesthetic dispensers for home use | Non-reactive and easy to clean | Heavy and breakable | Medium |

This analysis provides B2B buyers with critical insights into material selection for dog food auto dispensers, enabling informed decisions that align with market demands and compliance standards across different regions.

In-depth Look: Manufacturing Processes and Quality Assurance for dog food auto dispenser

What Are the Main Stages in the Manufacturing Process of Dog Food Auto Dispensers?

The manufacturing process for dog food auto dispensers involves several critical stages, each designed to ensure the final product meets quality standards and consumer expectations. Understanding these stages can empower B2B buyers to make informed decisions when selecting suppliers.

Material Preparation

The first stage of manufacturing involves sourcing and preparing the raw materials used in the production of auto dispensers. Common materials include high-grade plastics, metals, and electronic components. Suppliers often prioritize materials that are durable, non-toxic, and weather-resistant, especially for products intended for outdoor use. Advanced techniques such as material testing for safety and compliance with international standards are essential during this phase.

Forming Techniques: What Methods Are Used?

Once materials are prepared, they undergo various forming techniques. Injection molding is a prevalent method for shaping plastic components, allowing for complex designs and high-volume production. For metal parts, processes such as stamping and CNC machining are common. These techniques ensure precision and consistency across all units produced. B2B buyers should consider suppliers who utilize advanced forming technologies that enhance efficiency and reduce waste, ultimately leading to cost savings.

Illustrative image related to dog food auto dispenser

Assembly: How Are Components Integrated?

The assembly stage involves integrating all components into a final product. This includes the electronic circuitry, sensors, and mechanical parts. Automated assembly lines are often employed to improve efficiency and accuracy. Quality assurance checkpoints during assembly—such as in-process quality control (IPQC)—help identify defects early in the production process. Understanding the assembly techniques used by suppliers can provide insights into their operational capabilities and reliability.

Finishing: What Quality Enhancements Are Applied?

Finishing processes, such as surface treatment and coating, enhance the aesthetic and functional properties of the dispensers. These processes may involve painting, polishing, or applying anti-microbial coatings to ensure hygiene. The finishing stage is crucial, as it directly impacts the product’s durability and customer satisfaction. B2B buyers should inquire about the specific finishing techniques employed by suppliers, as these can affect the long-term performance of the dispensers.

What Quality Assurance Measures Are Essential for Dog Food Auto Dispensers?

Quality assurance (QA) is integral to the manufacturing process of dog food auto dispensers. It ensures that the final products meet both international standards and customer expectations.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are crucial for manufacturers aiming to ensure consistent quality management. Compliance with ISO standards indicates a commitment to quality and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can be important, particularly for products sold in specific markets like Europe and the Middle East.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing ensure that processes are adhered to and defects are caught early.

- Final Quality Control (FQC): The final product undergoes comprehensive testing before shipping to verify functionality and safety.

B2B buyers should look for suppliers that implement robust QC practices, as this directly impacts the reliability of the dispensers.

What Common Testing Methods Are Used?

Testing methods for dog food auto dispensers typically include:

- Functional Testing: Ensures the dispenser operates correctly under various conditions.

- Durability Testing: Assesses the product’s ability to withstand wear and tear.

- Safety Testing: Verifies compliance with health and safety regulations.

Understanding these testing methods allows B2B buyers to gauge the reliability of the products they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers. Here are some effective strategies:

What Role Do Audits and Reports Play?

Conducting supplier audits is a vital step in assessing their manufacturing and quality assurance capabilities. An audit can reveal insights into the supplier’s operational processes, workforce training, and adherence to quality standards. Additionally, requesting quality assurance reports can provide transparency regarding the supplier’s QC outcomes and compliance with international standards.

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing practices. These services can conduct random inspections at various stages of production, ensuring that quality standards are met consistently. For buyers in regions like Africa, South America, and the Middle East, utilizing third-party inspections can mitigate risks associated with local suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate unique challenges when dealing with quality control across different regions.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have varying regulations regarding product safety and quality. For instance, products sold in Europe must comply with CE regulations, while in the Middle East, specific certifications may be required. B2B buyers should ensure that their suppliers are familiar with and compliant with the relevant regulations in the target market.

Illustrative image related to dog food auto dispenser

What Should Buyers Know About Supply Chain Transparency?

Supply chain transparency is becoming increasingly important. Buyers should seek suppliers who are open about their sourcing, manufacturing processes, and quality control measures. This transparency not only fosters trust but also helps in identifying potential risks in the supply chain.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when selecting suppliers for dog food auto dispensers, ensuring that they receive high-quality, reliable products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dog food auto dispenser’

When sourcing a dog food auto dispenser, a systematic approach is essential to ensure you select the right product that meets both your business needs and the expectations of your customers. This checklist provides a clear pathway for B2B buyers to follow, ensuring a comprehensive evaluation of potential suppliers and products.

Illustrative image related to dog food auto dispenser

Step 1: Define Your Technical Specifications

Establishing the technical specifications is crucial to ensure that the auto dispenser meets the operational needs of your business. Consider factors such as capacity, type of food (dry or wet), power source (battery-operated or electric), and any smart features like app control or RFID recognition. Clearly defined specifications will streamline the selection process and help avoid miscommunication with suppliers.

Step 2: Research Market Trends and Customer Preferences

Understanding current market trends and customer preferences can provide insights into which features are most desirable. For instance, many consumers are seeking products that offer convenience and connectivity, such as Wi-Fi enabled dispensers that allow remote feeding schedules. Conducting surveys or analyzing sales data can help you gauge what features are in demand in different regions, such as Africa or Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it is crucial to vet suppliers thoroughly. Request company profiles, product specifications, and references from buyers in a similar industry or region. Check for certifications and compliance with international standards, as this can indicate the reliability and quality of their products.

- Supplier Credentials: Look for ISO certification or other quality assurance marks.

- Experience in Exporting: Ensure the supplier has experience in shipping to your target markets.

Step 4: Assess Product Quality and Features

Once you have shortlisted potential suppliers, assess the quality and features of their products. Request samples to evaluate the durability, ease of use, and functionality of the dispensers. Pay attention to customer feedback and product reviews, as they can provide valuable insights into the performance and reliability of the dispensers.

- Material Quality: Ensure the materials used are safe for pets and durable enough for long-term use.

- User-Friendly Design: Check for features that enhance usability, such as easy programming and maintenance.

Step 5: Negotiate Pricing and Terms of Purchase

Engage in negotiations to secure the best pricing and terms of purchase. Consider not just the unit price, but also shipping costs, bulk order discounts, and payment terms. Establish a clear agreement on delivery timelines to avoid disruptions in your supply chain.

- Bulk Discounts: Inquire about pricing tiers for larger orders.

- Payment Flexibility: Discuss payment terms that suit your cash flow needs.

Step 6: Verify Warranty and After-Sales Support

A strong warranty and reliable after-sales support are essential for maintaining customer satisfaction and addressing any product issues. Ensure the supplier offers a comprehensive warranty that covers defects and malfunctions. Additionally, inquire about the availability of replacement parts and customer service responsiveness.

- Warranty Duration: Look for warranties that last at least one year.

- Support Channels: Ensure there are multiple support channels available (e.g., phone, email, chat).

Step 7: Finalize Logistics and Distribution Plans

Once you have selected a supplier and product, finalize your logistics and distribution plans. Consider the most efficient shipping methods to your target markets and ensure compliance with local regulations. Establish relationships with local distributors if necessary to streamline the supply chain.

- Shipping Options: Evaluate costs and delivery times for various shipping methods.

- Local Regulations: Familiarize yourself with import regulations in your target markets to avoid delays.

By following this checklist, B2B buyers can confidently navigate the sourcing process for dog food auto dispensers, ensuring they choose the best products for their business needs.

Comprehensive Cost and Pricing Analysis for dog food auto dispenser Sourcing

What Are the Key Cost Components in Sourcing Dog Food Auto Dispensers?

When sourcing dog food auto dispensers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to dog food auto dispenser

-

Materials: The type of materials used significantly affects the overall cost. Common materials include durable plastics, stainless steel, and electronic components for smart features. Higher-quality materials may incur a higher upfront cost but can enhance product longevity and performance.

-

Labor: Labor costs vary based on the region where the dispensers are manufactured. Countries with lower labor costs might offer more competitive pricing, but this can sometimes come at the expense of quality.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial tooling costs for molds and dies can be significant, especially for custom designs. Buyers should factor these costs into their total investment, particularly if they require unique features or specifications.

-

Quality Control (QC): Implementing robust QC measures ensures the dispensers meet industry standards and customer expectations. While this adds to the cost, it can prevent costly recalls and damage to brand reputation.

-

Logistics: Shipping costs can vary greatly depending on the destination, shipping method, and weight of the products. Buyers should consider logistics costs as they significantly impact the total cost of ownership.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the market rates can help buyers negotiate better pricing.

How Do Price Influencers Affect the Cost of Dog Food Auto Dispensers?

Several factors influence the pricing of dog food auto dispensers, which buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk can lead to significant discounts. Suppliers often offer tiered pricing based on the volume, so negotiating for larger quantities can be beneficial.

-

Specifications and Customization: Customized dispensers with unique features (like RFID recognition or app connectivity) can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can add to the cost but may also enhance the product’s marketability and reliability.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more for their proven quality and service, while newer suppliers might offer lower prices to gain market entry.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for managing shipping responsibilities and costs. Different terms (e.g., FOB, CIF) can significantly impact the final price and responsibilities of both buyer and seller.

What Negotiation Strategies Can B2B Buyers Use?

To optimize costs while sourcing dog food auto dispensers, B2B buyers can employ several strategies:

-

Research and Compare: Conduct thorough market research to identify multiple suppliers and their offerings. This enables buyers to compare pricing, quality, and features effectively.

-

Negotiate Terms: Don’t hesitate to negotiate terms such as payment conditions, delivery timelines, and warranty services. Suppliers may be open to adjusting these terms to secure a deal.

-

Consider Total Cost of Ownership: Look beyond the initial price. Evaluate factors such as maintenance costs, durability, and warranty services to determine the true cost over the product’s lifecycle.

-

Understand Pricing Nuances in International Markets: Prices can vary significantly based on geographic location. Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions, tariffs, and taxes that may affect overall costs.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices for dog food auto dispensers may range from $50 to over $400, the actual cost will depend on the factors discussed above. Buyers should approach sourcing with a clear understanding of the cost components, price influencers, and negotiation strategies to secure favorable deals while ensuring product quality.

Alternatives Analysis: Comparing dog food auto dispenser With Other Solutions

Understanding Alternatives in Dog Feeding Solutions

In the competitive landscape of pet care, automatic dog food dispensers offer a convenient solution for pet owners. However, there are alternative methods and technologies that can achieve similar goals of efficient feeding and pet management. Understanding these alternatives allows B2B buyers to make informed decisions based on specific operational needs and customer preferences.

Illustrative image related to dog food auto dispenser

Comparison Table

| Comparison Aspect | Dog Food Auto Dispenser | Gravity Feeders | Manual Feeding Solutions |

|---|---|---|---|

| Performance | Automated portion control | Continuous supply of food | User-dependent portion control |

| Cost | Ranges from $50 to $500 | Typically $20 to $100 | Variable; depends on labor costs |

| Ease of Implementation | Requires setup and occasional calibration | Easy setup; minimal maintenance | Simple; requires time and attention |

| Maintenance | Requires cleaning and occasional battery replacement | Low maintenance; periodic cleaning required | High maintenance; regular feeding needed |

| Best Use Case | Ideal for busy pet owners or those with multiple pets | Suitable for pet owners who prefer a low-effort solution | Best for small households or pet owners present at home |

Detailed Breakdown of Alternatives

1. Gravity Feeders

Gravity feeders are a popular alternative to automatic dog food dispensers. They operate on a simple mechanism where food is dispensed by gravity into the bowl as it is consumed. This type of feeder is cost-effective and requires minimal setup, making it an attractive option for budget-conscious buyers. However, gravity feeders do not allow for portion control, potentially leading to overeating. They are best suited for pet owners who want a low-effort solution and are less concerned about meal timing or portions.

2. Manual Feeding Solutions

Manual feeding involves the traditional method of serving food at set times by the pet owner. This method is straightforward and allows for full control over portion sizes, which can be crucial for pets with dietary restrictions. While it is the most economical in terms of initial investment, it demands a significant time commitment and can be inconsistent if the owner is busy or away. Manual feeding is ideal for households with one or two pets where owners are available to manage mealtimes actively.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a feeding solution for dogs, B2B buyers must consider the specific requirements of their target market. Automatic dog food dispensers are ideal for pet owners who prioritize convenience and precision in feeding. In contrast, gravity feeders and manual feeding solutions may appeal to those looking for cost-effective or traditional methods. Ultimately, understanding the unique benefits and limitations of each option will enable businesses to cater effectively to diverse customer needs, ensuring satisfaction and fostering loyalty in the pet care industry.

Illustrative image related to dog food auto dispenser

Essential Technical Properties and Trade Terminology for dog food auto dispenser

What Are the Key Technical Properties of Dog Food Auto Dispensers?

When evaluating dog food auto dispensers, several technical properties are crucial for ensuring product quality and functionality. Understanding these specifications can help B2B buyers make informed decisions.

-

Material Grade

The material used in constructing the dispenser significantly impacts its durability and safety. Common materials include BPA-free plastics, stainless steel, and food-grade silicone. Selecting high-quality materials ensures that the product is not only safe for pets but also resistant to wear and tear, making it suitable for various environments. -

Capacity

The capacity of an automatic dog feeder is a vital specification that determines how much food it can hold at one time. Typical capacities range from 2 liters to 8 liters. A larger capacity is beneficial for businesses that cater to multiple pets or for pet owners who prefer less frequent refilling. This specification is particularly important for B2B buyers in regions where access to regular supply might be limited. -

Power Source

Dog food dispensers can be powered by batteries, mains electricity, or both. Battery-operated models offer portability and flexibility, while electric models provide consistent performance. Understanding the power source is essential for businesses considering the operational logistics of the product in different markets, especially in areas with unstable electricity supply. -

Programmable Features

Programmable settings allow users to schedule feeding times and portion sizes. This feature is crucial for maintaining a pet’s dietary routine and can be a selling point for B2B buyers focused on health and nutrition. Automatic programming enhances convenience, making it an attractive option for busy pet owners. -

Sensor Technology

Advanced models may incorporate sensor technology, such as RFID pet recognition or motion sensors. This technology enhances user experience by personalizing feeding schedules based on individual pet needs. For B2B buyers, investing in technology-driven products can provide a competitive edge in the market. -

Ease of Cleaning

Dispenser designs should facilitate easy cleaning to maintain hygiene standards. Removable components and dishwasher-safe materials are significant advantages. B2B buyers should prioritize products that offer user-friendly maintenance to ensure long-term customer satisfaction.

What Are Common Trade Terms in the Dog Food Auto Dispenser Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some critical terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate better terms, especially in bulk purchasing scenarios. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to manage inventory effectively and avoid excess stock that can tie up capital. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. This process allows buyers to compare offers and make informed purchasing decisions. Crafting a clear RFQ can lead to better negotiation outcomes. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping responsibilities, costs, and risk management when sourcing products globally. -

Lead Time

Lead time is the duration between placing an order and receiving the product. Understanding lead times is crucial for inventory planning and ensuring that supply meets demand, especially in dynamic markets. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product. A robust warranty can indicate a supplier’s confidence in their product and provide buyers with peace of mind regarding potential defects or issues.

By understanding these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing dog food auto dispensers effectively, ensuring they meet market demands while maintaining product quality.

Navigating Market Dynamics and Sourcing Trends in the dog food auto dispenser Sector

What Are the Key Trends Shaping the Dog Food Auto Dispenser Market?

The global dog food auto dispenser market is experiencing robust growth driven by several factors. As urbanization increases, pet ownership rates are on the rise, particularly in emerging markets across Africa, South America, and the Middle East. Consumers are increasingly seeking convenience and efficiency in pet care solutions, which has led to a surge in demand for automatic feeders. Additionally, the integration of technology, such as app connectivity and RFID recognition, is transforming traditional feeding practices into personalized experiences. This trend is particularly relevant for B2B buyers looking to offer innovative solutions that cater to tech-savvy pet owners.

Moreover, sustainability is becoming a pivotal consideration in product development. Manufacturers are responding to consumer preferences for eco-friendly products by incorporating sustainable materials and practices into their designs. As a result, B2B buyers are encouraged to source products that not only meet performance standards but also align with environmental values. The rise of subscription-based models, which facilitate recurring purchases of consumables like food and replacement parts, is also noteworthy. This model offers opportunities for businesses to enhance customer loyalty while ensuring a steady revenue stream.

Illustrative image related to dog food auto dispenser

How Important Is Sustainability and Ethical Sourcing in the Dog Food Auto Dispenser Sector?

Sustainability and ethical sourcing are increasingly critical in the dog food auto dispenser market. Consumers are becoming more aware of the environmental impact of their purchases, prompting manufacturers to adopt greener practices. This includes using recyclable materials for dispensers and packaging, as well as minimizing waste during production. B2B buyers should prioritize suppliers who can demonstrate commitment to sustainable practices, as this can enhance brand reputation and customer trust.

Ethical supply chains are also essential, especially in regions with varying labor laws and environmental regulations. Buyers should seek partners who uphold high standards for labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. By investing in ethically sourced products, B2B buyers can not only fulfill their corporate social responsibilities but also tap into a growing market segment that values transparency and sustainability.

What Is the Evolution of the Dog Food Auto Dispenser Industry?

The evolution of the dog food auto dispenser industry has been marked by technological advancements and changing consumer preferences. Initially, automatic feeders were basic devices that simply dispensed food at set intervals. However, as pet ownership became more prevalent and technology advanced, these products evolved into sophisticated systems equipped with features such as programmable timers, portion control, and even remote monitoring via smartphone apps.

The rise of the smart home trend has further accelerated this evolution, leading to the integration of IoT technology in pet care products. This shift not only enhances the convenience for pet owners but also opens up new avenues for B2B buyers to explore cutting-edge innovations in the market. As the industry continues to mature, staying abreast of these developments will be crucial for businesses aiming to remain competitive and meet the evolving demands of pet owners globally.

Illustrative image related to dog food auto dispenser

Frequently Asked Questions (FAQs) for B2B Buyers of dog food auto dispenser

-

How do I choose the right dog food auto dispenser for my business needs?

Selecting the appropriate dog food auto dispenser involves assessing your target market’s requirements, the type of dog food you plan to dispense (dry, wet, or both), and the feeder’s capacity. Consider dispensers with programmable features for portion control and meal timing, as these are increasingly popular among pet owners. Additionally, evaluate the ease of cleaning and maintenance, as well as any smart features like app connectivity or camera monitoring, which can enhance user experience and provide added value. -

What are the key features to look for in an automatic dog feeder?

When sourcing automatic dog feeders, focus on features that ensure convenience and functionality. Look for programmable timers, adjustable portion sizes, and compatibility with different food types. Smart connectivity, such as Wi-Fi or Bluetooth, allows for remote feeding control and monitoring. Additional features like RFID pet recognition, dual food trays, and vacuum-sealing technology for freshness can differentiate your product and cater to diverse consumer preferences. -

What are the common payment terms for B2B purchases of dog food auto dispensers?

Payment terms can vary significantly based on supplier policies and the buyer’s creditworthiness. Common arrangements include net 30, net 60, or upfront payment before shipment. For larger orders, consider negotiating terms that may include a deposit with the balance due upon delivery. Always clarify payment methods accepted, such as wire transfer, credit terms, or letters of credit, to ensure a smooth transaction process. -

How can I vet suppliers for dog food auto dispensers?

To effectively vet suppliers, conduct thorough research on their reputation, product quality, and compliance with international standards. Request references and reviews from other B2B buyers. Verify their manufacturing capabilities, certifications, and experience in exporting to your region. Additionally, consider conducting site visits or audits if feasible, and ask for samples to assess product quality firsthand before committing to larger orders. -

What is the minimum order quantity (MOQ) for dog food auto dispensers?

MOQs can vary widely among suppliers based on production capabilities and the specific product. Typically, you might encounter MOQs ranging from 50 to several hundred units. It’s important to discuss these terms upfront and understand any flexibility in ordering. Some suppliers may offer lower MOQs for initial orders or promotional trials, making it easier for new buyers to enter the market without substantial upfront investment. -

What logistics considerations should I keep in mind when importing dog food auto dispensers?

Importing dog food auto dispensers involves understanding shipping options, customs regulations, and potential tariffs. Choose a reliable freight forwarder who can assist with documentation and ensure compliance with import/export laws. Factor in shipping times and costs, as well as insurance to protect your investment. Additionally, be aware of any specific packaging or labeling requirements in your target market to avoid delays during customs clearance. -

How do I ensure quality assurance (QA) for imported dog food auto dispensers?

Establishing a robust QA process is crucial for maintaining product standards. Request samples before placing bulk orders to evaluate quality and functionality. Develop a checklist that includes criteria for material quality, durability, and compliance with safety standards. Consider third-party inspections during production and before shipment to ensure adherence to specifications. Regularly review supplier performance and feedback to address any quality issues promptly. -

What are the best practices for marketing dog food auto dispensers in international markets?

To effectively market dog food auto dispensers, tailor your approach to fit the cultural and economic context of each target market. Utilize digital marketing strategies, such as social media and influencer partnerships, to reach pet owners. Highlight unique features that resonate with local needs, such as energy efficiency or ease of use. Attend trade shows to network and showcase products, and consider localized advertising campaigns to build brand awareness and trust in your target region.

Top 6 Dog Food Auto Dispenser Manufacturers & Suppliers List

1. Petlibro – Automatic Pet Feeders

Domain: petlibro.com

Registered: 2019 (6 years)

Introduction: Automatic Pet Feeders for Cats and Dogs – Petlibro offers a variety of feeders including the Polar Smart Wet Food Feeder, Granary Seamless Dry Food Feeders, and Air Smart Feeders. Key features include RFID pet recognition, app control, vacuum sealing technology, and dual food trays. The feeders come in various capacities (2L, 3L, 5L, 8L) and price ranges from under $50 to over $100. Free shipping …

2. Houndsy – Kibble Dispenser

Domain: houndsy.com

Registered: 2018 (7 years)

Introduction: {“Houndsy Kibble Dispenser”:{“description”:”A mid-century modern dog kibble storage and dispenser system.”,”starting_price”:”$195 USD”,”limited_time_offer”:”20% OFF”,”color”:”Essential Series – Black”,”sizes_available”:[{“size”:”Standard”,”ideal_for”:”small dogs”},{“size”:”Elevated”,”ideal_for”:”medium/large dogs”}],”bowl_sizes”:[“½ cup”,”¾ cup”,”1 cup”,”1 ½ cups”,”2 cups”,”2 ½ cups”,”3 ½ cups”],”…

3. PetSafe® – Smart Feed Automatic Dog and Cat Feeder

Domain: petsafe.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Smart Feed Automatic Dog and Cat Feeder, 2nd Generation”, “brand”: “PetSafe®”, “price”: “$134.99”, “capacity”: “24 cups”, “number_of_meals”: “12”, “meal_scheduler”: “Customize meal times”, “features”: [“Wi-Fi enabled”, “Alexa compatible”, “iPhone & Android compatible”], “refill_type”: “Automatic”, “sensors”: [“Low food sensor”, “Empty food sensor”], “meal_sizes”: “1/8 cup to 4 cu…

4. PetSmart – Automatic Dog Feeders & Water Dispensers

Domain: petsmart.com

Registered: 1995 (30 years)

Introduction: Automatic Dog Feeders & Dog Water Dispensers available at PetSmart. Key brands include PETLIBRO, PetSafe, Top Paw, Pioneer Pet, Trixie, Cat Mate, Petmate, Sure Petcare, Instachew, and Neater Pets. Price range from $0 to $299.99. Features include programmable timers for meal scheduling, dry or semi-moist food compatibility, and options for multiple daily feedings. Products include PetSafe® 5 Meal P…

5. Top Pets – Automatic Dog Feeder 8L

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Automatic dog feeders recommended for larger breeds, air-tight design, ability to program multiple dispense times, and features like voice recording to call the dog for feeding. Specific brands mentioned include one from ‘Top Pets’ and a model with an 8L capacity.

6. Petlibro – Automatic Dog Feeder with Camera

Domain: goodhousekeeping.com

Registered: 1995 (30 years)

Introduction: 1. Best Overall: Petlibro Automatic Dog Feeder with Camera – Price: $105 (originally $160), Capacity: 5 L (about 21 cups), Portion size: 1/12 cup to about 4 cups, Max feedings: 10 per day, App-enabled: Yes, Power: Plug-in with battery backup, Features: HD camera, two-way audio, night vision, personalized message playback.

2. Best Value: PetSafe Automatic Dog Feeder – Price: $57 (originally $65),…

Strategic Sourcing Conclusion and Outlook for dog food auto dispenser

In conclusion, the strategic sourcing of dog food auto dispensers presents significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By aligning with reputable suppliers who offer innovative features such as RFID recognition, app connectivity, and customizable feeding schedules, businesses can enhance customer satisfaction and streamline operations.

Investing in high-quality automatic feeders not only meets the growing demand for convenience but also addresses the evolving needs of pet owners who prioritize their pets’ health and well-being. As the market for pet care continues to expand, sourcing partners who emphasize technology and sustainability will be vital for success.

Looking ahead, it is crucial for B2B buyers to leverage market insights and supplier capabilities to create strategic partnerships that foster growth and innovation. By prioritizing quality and functionality in their sourcing decisions, businesses can position themselves at the forefront of the pet care industry. Engage with suppliers today to explore how dog food auto dispensers can elevate your offerings and meet the demands of modern pet ownership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to dog food auto dispenser

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.