Introduction: Navigating the Global Market for how often should i change hummingbird feeder

Navigating the global market for hummingbird feeders presents unique challenges, particularly when it comes to understanding how often to change hummingbird feeder nectar. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Saudi Arabia—making informed decisions is crucial. Hummingbird feeders are not just a product; they represent a commitment to biodiversity and customer satisfaction in avian-related businesses.

This comprehensive guide delves into the various aspects of hummingbird feeder maintenance, including the ideal nectar replacement frequency, types of feeders, and their applications across different climates. Additionally, it covers essential supplier vetting processes, cost considerations, and best practices for ensuring product quality. By addressing these key areas, the guide empowers B2B buyers to navigate their sourcing decisions effectively, ensuring they provide the best products for their markets.

With insights tailored to diverse geographic and climatic conditions, this guide is an invaluable resource for businesses aiming to enhance their offerings and support the health of hummingbird populations globally. By prioritizing fresh nectar and understanding the nuances of feeder maintenance, buyers can elevate their brand reputation and contribute positively to the environment.

Table Of Contents

- Top 2 How Often Should I Change Hummingbird Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how often should i change hummingbird feeder

- Understanding how often should i change hummingbird feeder Types and Variations

- Key Industrial Applications of how often should i change hummingbird feeder

- 3 Common User Pain Points for ‘how often should i change hummingbird feeder’ & Their Solutions

- Strategic Material Selection Guide for how often should i change hummingbird feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for how often should i change hummingbird feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often should i change hummingbird feeder’

- Comprehensive Cost and Pricing Analysis for how often should i change hummingbird feeder Sourcing

- Alternatives Analysis: Comparing how often should i change hummingbird feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for how often should i change hummingbird feeder

- Navigating Market Dynamics and Sourcing Trends in the how often should i change hummingbird feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how often should i change hummingbird feeder

- Strategic Sourcing Conclusion and Outlook for how often should i change hummingbird feeder

- Important Disclaimer & Terms of Use

Understanding how often should i change hummingbird feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seasonal Nectar Change | Adjusts frequency based on seasonal temperature changes. | Retailers in diverse climates. | Pros: Aligns with natural feeding patterns. Cons: Requires monitoring temperature. |

| Humidity-Dependent Change | Changes nectar more frequently in humid conditions. | Tropical and subtropical markets. | Pros: Prevents spoilage in high humidity. Cons: Increased maintenance. |

| Standard Routine Change | Fixed schedule (e.g., every 2-4 days). | General retailers and suppliers. | Pros: Easy to manage. Cons: May not suit all climates. |

| Emergency Change Protocol | Immediate nectar change in case of spoilage signs. | Emergency response for suppliers. | Pros: Ensures bird health. Cons: Requires vigilance. |

| Visitor-Triggered Change | Adjusts based on feeder activity levels. | Businesses focusing on birdwatching. | Pros: Efficient use of resources. Cons: Requires monitoring and data collection. |

What Are the Characteristics of Seasonal Nectar Change?

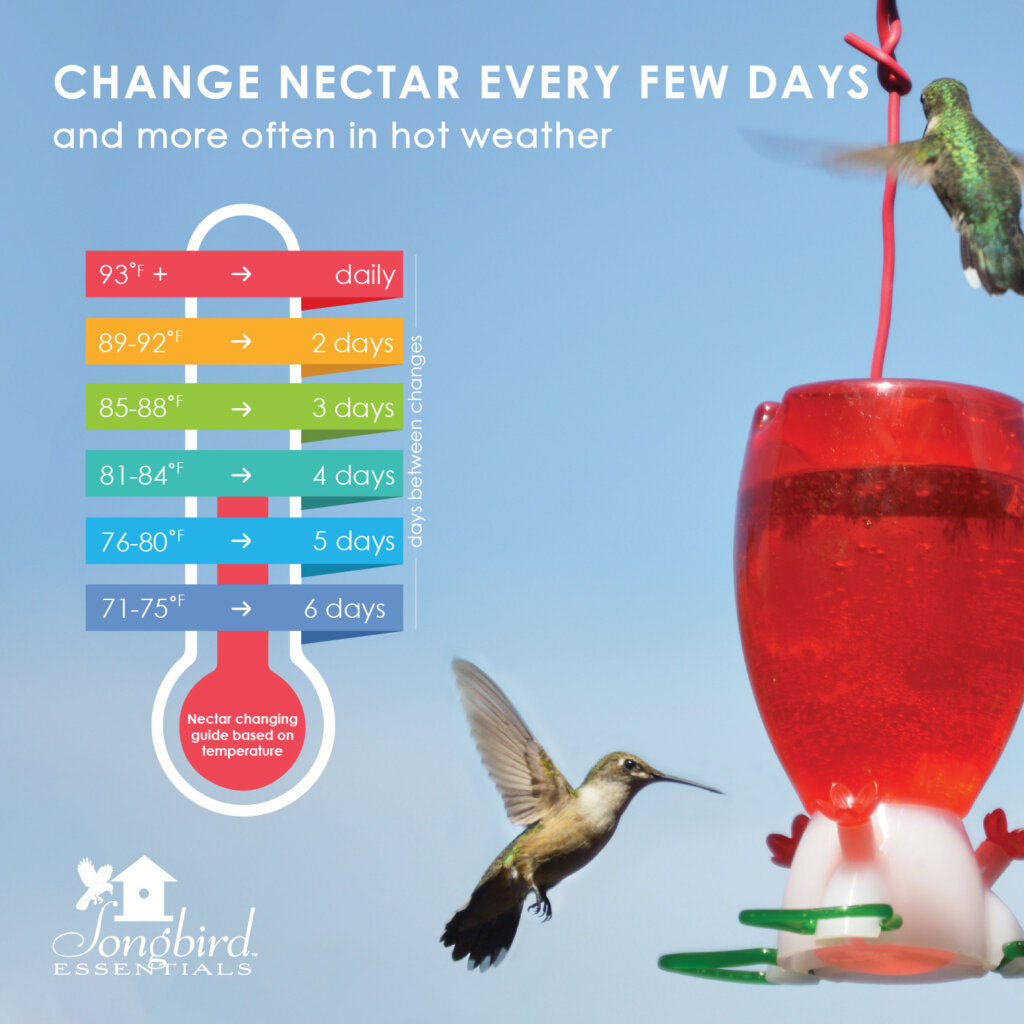

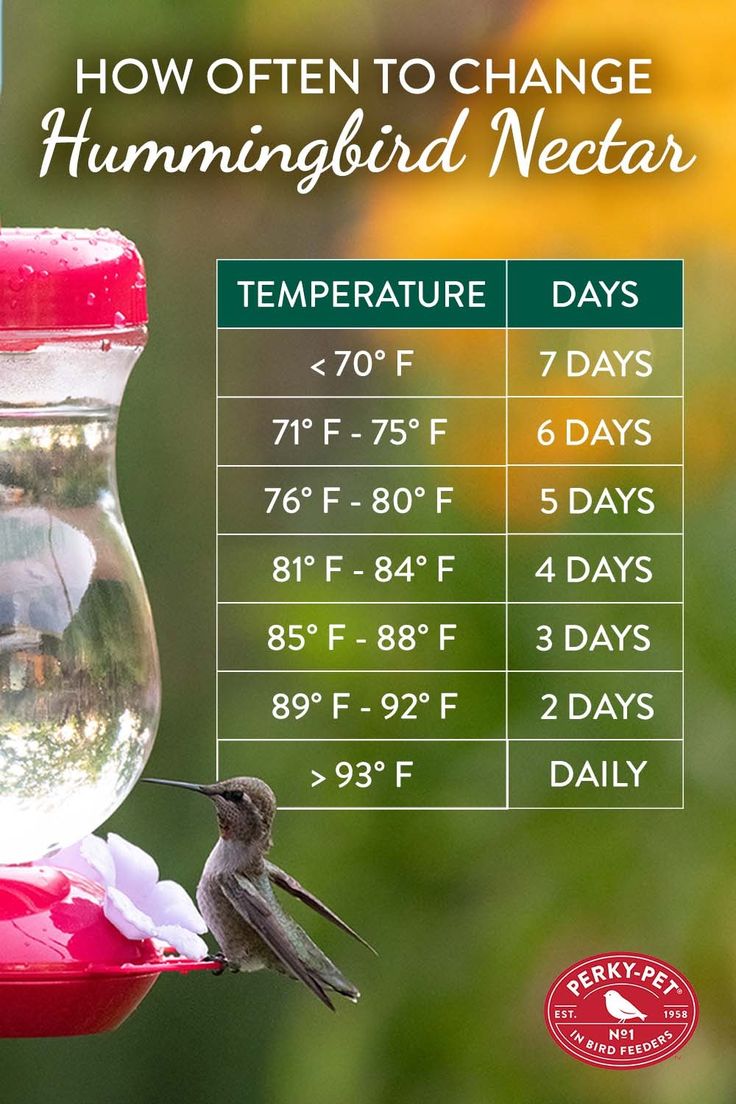

Seasonal nectar change protocols are vital for businesses operating in regions with fluctuating temperatures. Retailers need to adapt their nectar change frequency based on the local climate. For instance, in cooler months, nectar can be changed every 2-3 days, while in warmer months, daily changes may be necessary. This type of protocol ensures that the hummingbirds receive fresh nectar, promoting their health and encouraging repeat visits, which is essential for businesses relying on birdwatching tourism.

How Does Humidity-Dependent Change Impact Nectar Maintenance?

Humidity-dependent nectar change is particularly relevant for businesses in tropical or subtropical regions where high moisture levels can lead to rapid nectar spoilage. In such environments, nectar should be changed every 1-2 days to maintain freshness and prevent fermentation. This approach not only supports the health of the birds but also enhances customer satisfaction for retailers who prioritize the well-being of wildlife. Understanding local weather patterns can significantly inform purchasing decisions for nectar products.

Why is a Standard Routine Change Beneficial for General Retailers?

A standard routine change, typically every 2-4 days, offers a straightforward approach for general retailers and suppliers. This method simplifies inventory management and ensures that products are replenished regularly without requiring constant monitoring. However, businesses must consider their specific regional climates to ensure that this schedule aligns with local conditions. While this method is convenient, it may not be optimal for areas with extreme weather fluctuations.

What Should Businesses Know About Emergency Change Protocols?

Emergency change protocols are crucial for suppliers and retailers who want to ensure the health of the birds they serve. If signs of spoilage are detected—such as discoloration or an unusual odor—immediate nectar changes are necessary. This proactive approach helps maintain a positive reputation among customers who value wildlife care. While this requires vigilance and quick action, it ultimately supports the sustainability of bird populations and enhances customer trust.

How Can Visitor-Triggered Change Optimize Resources?

Visitor-triggered change protocols allow businesses to adjust nectar change frequency based on actual feeder activity. This method involves monitoring hummingbird visits and changing nectar accordingly, which can lead to more efficient use of resources. While this approach may require additional data collection and monitoring, it can significantly enhance the effectiveness of feeding strategies, making it particularly appealing for businesses focused on birdwatching and conservation efforts.

Key Industrial Applications of how often should i change hummingbird feeder

| Industry/Sector | Specific Application of how often should i change hummingbird feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture & Horticulture | Regularly changing nectar to attract pollinators for crop yield | Enhanced pollination leads to improved crop production and profitability | Sourcing high-quality feeders and nectar formulations suited for local climates |

| Hospitality & Tourism | Maintaining feeders in gardens to attract guests and enhance experience | Increased customer satisfaction and repeat business | Durable feeders that are easy to clean and maintain, suited for outdoor conditions |

| Environmental Conservation | Monitoring and changing nectar to support local hummingbird populations | Promotes biodiversity and ecosystem health | Compliance with local wildlife regulations and sourcing sustainable materials |

| Retail & E-commerce | Providing guidance on nectar freshness to customers | Builds brand reputation and customer loyalty | Offering educational content and high-quality products that meet consumer needs |

| Landscaping Services | Implementing feeder maintenance in residential and commercial properties | Improves aesthetic appeal and wildlife engagement for clients | Knowledge of local bird species and feeder designs that minimize maintenance |

In the Agriculture & Horticulture sector, businesses can leverage the knowledge of how often to change hummingbird feeders to enhance pollination rates in crops. Regularly changing nectar not only attracts hummingbirds but also ensures that these vital pollinators are present when crops are blooming. For buyers in regions like Africa and South America, understanding local climatic conditions is essential for sourcing feeders that can withstand specific weather patterns, thereby maximizing agricultural yield.

For the Hospitality & Tourism industry, maintaining hummingbird feeders can significantly enhance the guest experience in gardens and outdoor spaces. By ensuring that nectar is fresh and readily available, businesses can attract these beautiful birds, creating a serene and engaging environment for visitors. Buyers in this sector should focus on durable feeders that require minimal maintenance while fitting aesthetically into their landscape designs.

In Environmental Conservation, organizations can use the knowledge of nectar maintenance to support local ecosystems. Regularly changing nectar in feeders helps sustain hummingbird populations, which are critical for biodiversity. For international buyers, especially in the Middle East and Europe, it’s crucial to consider local wildlife regulations and sourcing sustainable materials that align with conservation goals.

The Retail & E-commerce sector can benefit from educating customers on the importance of nectar freshness. Providing clear guidelines on how often to change hummingbird feeders can enhance customer satisfaction and foster brand loyalty. Retailers should consider offering high-quality products and educational resources that cater to diverse consumer needs across different regions.

Lastly, Landscaping Services can incorporate hummingbird feeder maintenance as part of their offerings, enhancing the aesthetic appeal of properties. By ensuring that feeders are regularly cleaned and stocked with fresh nectar, landscaping professionals can create vibrant environments that attract wildlife. Buyers in this space should be knowledgeable about local bird species and select feeder designs that minimize maintenance while maximizing visual appeal.

3 Common User Pain Points for ‘how often should i change hummingbird feeder’ & Their Solutions

Scenario 1: Struggling with Nectar Spoilage in Hot Climates

The Problem: B2B buyers operating in warmer climates often face the challenge of nectar spoilage. In regions like parts of Africa and the Middle East, where temperatures can soar above 90°F (32°C), nectar can spoil within a day. This not only affects the health of the hummingbirds but also leads to wasted resources for businesses that rely on attracting these birds for tourism or agricultural pollination. Buyers may find themselves scrambling to replace nectar frequently, leading to operational inefficiencies and potential loss of customer interest.

The Solution: To mitigate nectar spoilage, it is crucial to establish a regular schedule for changing nectar, especially during peak heat. Implementing a system that includes daily checks of feeder conditions can help. Buyers can use temperature tracking apps to monitor daily highs and lows, adjusting their nectar replacement schedule accordingly. For example, on extremely hot days, nectar should be changed every 24 hours. Additionally, consider investing in insulated feeders that help maintain cooler nectar temperatures longer. This proactive approach ensures hummingbirds remain healthy and engaged, ultimately enhancing the business’s reputation in the ecological tourism sector.

Scenario 2: Inconsistent Hummingbird Visits Due to Poor Nectar Management

The Problem: Businesses that aim to attract hummingbirds often experience inconsistent visitor patterns, which can be attributed to poor nectar management. Inconsistent nectar freshness can lead to birds avoiding feeders, as they quickly learn to associate them with spoiled nectar. This is particularly critical for businesses in regions like South America, where biodiversity is a key draw for eco-tourism.

Illustrative image related to how often should i change hummingbird feeder

The Solution: Establish a standardized process for nectar management that includes monitoring feeder cleanliness and nectar freshness. Buyers should implement a two-day maximum for nectar replacement in moderate climates and consider weekly cleaning routines to prevent mold and bacteria buildup. Utilizing bright-colored, visually appealing feeders can help attract hummingbirds, but they must be complemented with fresh nectar. Additionally, training staff on the signs of spoilage—such as cloudiness or a foul smell—can ensure quick action is taken to maintain feeder attractiveness. By committing to these best practices, businesses can create a reliable feeding environment that keeps hummingbirds returning, enhancing customer experiences.

Scenario 3: Attracting Hummingbirds While Managing Insect Problems

The Problem: Insects such as bees and wasps can become a significant issue for businesses attempting to attract hummingbirds, particularly in regions with abundant floral life. These pests not only deter hummingbirds but can also create an unpleasant experience for customers who come to enjoy birdwatching. Buyers may feel frustrated when their efforts to create an inviting environment are undermined by unwanted insects.

The Solution: To effectively manage insect problems while keeping hummingbirds happy, buyers should adopt a multi-faceted approach. First, ensure that feeders are placed away from yellow flowers or decorations, as these attract bees. Secondly, consider using bee guards on feeders, which allow hummingbirds access while keeping larger insects out. Additionally, creating a separate, ground-level feeding station with a higher sugar concentration (1:1 ratio) can divert bees away from hummingbird feeders. Regularly changing nectar is essential; it should be done at least every two to four days, depending on weather conditions. Educating staff about these strategies can also empower them to maintain a pest-free environment, ensuring that hummingbirds continue to thrive and attract customers to the business.

Strategic Material Selection Guide for how often should i change hummingbird feeder

What Materials Are Commonly Used for Hummingbird Feeders?

When selecting materials for hummingbird feeders, it is essential to consider properties that affect their performance, durability, and suitability for various environments. Here, we analyze four common materials used in the manufacturing of hummingbird feeders: glass, plastic, metal, and silicone.

Glass: A Classic Choice for Hummingbird Feeders

Key Properties: Glass is known for its excellent temperature resistance and non-reactive nature, making it ideal for containing nectar without altering its flavor. It is also easy to clean, which is crucial for maintaining freshness.

Pros & Cons: The primary advantage of glass is its durability and aesthetic appeal, offering a premium look that can attract more customers. However, it is heavier and more prone to breakage compared to other materials, which can lead to higher shipping costs and potential safety concerns.

Impact on Application: Glass feeders are less likely to warp under high temperatures, making them suitable for warmer climates. However, they can be less practical in areas with extreme weather conditions, such as heavy winds or hail.

International Considerations: For buyers in regions like Africa and the Middle East, where temperatures can soar, ensuring that glass feeders are treated to withstand UV exposure is vital. Compliance with local safety standards is also crucial.

Plastic: Versatile and Lightweight

Key Properties: Plastic is lightweight, resistant to corrosion, and can be molded into various shapes and colors. It is often treated to withstand UV rays and temperature fluctuations.

Pros & Cons: The main advantage of plastic is its affordability and ease of manufacturing, which allows for mass production. However, lower-quality plastics can degrade over time, leading to potential leaching of harmful chemicals into the nectar.

Impact on Application: Plastic feeders are often designed for easy cleaning and refilling, making them user-friendly. However, they may not be as durable as glass or metal, particularly in extreme weather conditions.

International Considerations: Buyers in Europe may prefer plastics that comply with EU regulations regarding food safety. In regions like South America, where humidity can be high, selecting high-grade plastic that resists mold growth is essential.

Metal: Durable and Long-Lasting

Key Properties: Metals such as aluminum or stainless steel offer excellent corrosion resistance and durability. They can withstand harsh weather conditions without degrading.

Pros & Cons: Metal feeders are incredibly durable and can last for years, making them a good investment. However, they can be heavier and more expensive than plastic options, and some metals may rust if not properly coated.

Impact on Application: Metal feeders can be designed to be more robust, making them suitable for outdoor use in various climates. However, they may conduct heat, potentially warming the nectar, which could deter hummingbirds.

International Considerations: Buyers in regions with high humidity, such as parts of Africa, should ensure that metals are treated to prevent corrosion. Compliance with international standards for food safety is also a must.

Silicone: A Flexible and Innovative Option

Key Properties: Silicone is flexible, heat-resistant, and non-toxic, making it an excellent choice for seals and gaskets in feeders. It can withstand a wide range of temperatures.

Pros & Cons: The flexibility of silicone allows for easier assembly and disassembly of feeders, making cleaning more straightforward. However, it may not provide the same aesthetic appeal as glass or metal options.

Impact on Application: Silicone can be used in conjunction with other materials to enhance the sealing capabilities of feeders, preventing leaks. However, it may not be as durable as other materials when exposed to harsh weather conditions over time.

International Considerations: For B2B buyers in the Middle East, where temperatures can fluctuate dramatically, ensuring that silicone components are rated for high-temperature use is essential. Compliance with local health and safety standards is also critical.

Summary Table of Material Selection for Hummingbird Feeders

| Material | Typical Use Case for how often should i change hummingbird feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Premium feeders for aesthetic appeal and durability | Non-reactive and easy to clean | Heavy and prone to breakage | Medium |

| Plastic | Budget-friendly, lightweight feeders for mass production | Affordable and versatile | Can degrade and leach chemicals | Low |

| Metal | Robust feeders for long-term outdoor use | Highly durable and corrosion-resistant | Heavier and may rust | High |

| Silicone | Flexible seals and gaskets in feeders | Heat-resistant and non-toxic | May lack aesthetic appeal | Medium |

This analysis provides valuable insights for B2B buyers considering the best materials for hummingbird feeders, taking into account performance, durability, and international compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how often should i change hummingbird feeder

What Are the Main Stages of Manufacturing Hummingbird Feeders?

Manufacturing hummingbird feeders involves several critical stages that ensure the final product is both functional and appealing to consumers. Understanding these stages is essential for B2B buyers looking to source high-quality feeders.

Material Preparation: What Materials Are Used in Hummingbird Feeders?

The first step in the manufacturing process is material preparation. Hummingbird feeders are typically made from durable materials such as glass, plastic, and metal. Each material has its advantages; for example, glass feeders are favored for their aesthetic appeal and ease of cleaning, while plastic feeders are lightweight and often more affordable.

During this stage, raw materials are sourced from suppliers who meet industry standards. Buyers should consider the environmental impact of these materials, as sustainability is becoming increasingly important in global markets.

Illustrative image related to how often should i change hummingbird feeder

How Are Hummingbird Feeders Formed?

Following material preparation, the forming stage begins. This involves shaping the materials into the desired components of the feeder, such as the reservoir and feeding ports. Techniques like injection molding are commonly used for plastic parts, while glass components may be blown or pressed into shape.

It’s crucial that manufacturers maintain strict dimensional tolerances during this stage to ensure that all parts fit together properly, which affects both the feeder’s functionality and its aesthetic appeal.

What Is the Assembly Process for Hummingbird Feeders?

Once the individual components are formed, the assembly process takes place. This stage typically involves the following steps:

- Component Integration: Workers or machines assemble the feeder parts, ensuring that the reservoir, feeding ports, and any decorative elements are securely attached.

- Seal Testing: To prevent leaks, the feeder’s seals are tested for integrity. This is vital, as any leakage can lead to nectar spoilage, which is a key consideration for end-users.

- Final Assembly: The final product is put together, including any additional features such as ant moats or bee guards.

What Finishing Techniques Are Applied to Hummingbird Feeders?

The finishing stage enhances both the durability and appearance of the hummingbird feeders. Techniques may include:

Illustrative image related to how often should i change hummingbird feeder

- Surface Treatments: Coatings are often applied to prevent rusting or fading, especially for metal feeders. These may include powder coating or anodizing.

- Quality Control Inspections: Each batch undergoes a quality inspection to ensure that the finish meets the required standards, checking for consistency in color and texture.

What Are the Key Quality Control Measures for Hummingbird Feeders?

Quality assurance in the manufacturing of hummingbird feeders is critical to ensure safety and customer satisfaction. Key quality control measures include:

What International Standards Should Buyers Be Aware Of?

B2B buyers should be aware of international standards such as ISO 9001, which outlines criteria for quality management systems. Compliance with such standards signifies a commitment to quality and continuous improvement.

In addition, specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for materials may be relevant. These certifications can assure buyers of the product’s quality and safety.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints should be integrated throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, random samples are tested to catch any deviations early.

- Final Quality Control (FQC): The completed feeders undergo a comprehensive inspection before packaging and shipping.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods may include:

- Leak Tests: Ensuring that feeders do not leak is crucial for customer satisfaction.

- Material Durability Tests: Assessing how well materials withstand environmental factors like UV exposure, temperature variations, and humidity.

- User Safety Tests: Ensuring that all components are safe for both birds and humans, including non-toxic materials and secure designs.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Here are some effective strategies:

- Supplier Audits: Conducting regular audits can help verify compliance with quality standards and assess the effectiveness of the manufacturing process.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes and results, including any certifications or test results.

- Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality control practices.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following nuances:

- Cultural Differences: Understanding local practices and expectations can help in negotiating terms and ensuring that quality standards are met.

- Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. It’s essential to be familiar with these regulations to avoid legal issues.

- Logistics and Supply Chain: International shipping can introduce risks related to product damage or delays. Therefore, quality checks should also consider the logistics aspect.

Conclusion

For B2B buyers in the hummingbird feeder market, understanding the manufacturing processes and quality assurance measures is essential. By focusing on material preparation, forming, assembly, and finishing stages, along with rigorous quality control practices, buyers can ensure they source high-quality products that meet international standards. Engaging with suppliers who prioritize quality will not only satisfy end-users but also enhance brand reputation in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how often should i change hummingbird feeder’

In the realm of sourcing hummingbird feeders, understanding the optimal frequency for changing nectar is crucial for ensuring the health and attraction of these birds. This guide outlines a structured approach for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. By adhering to this checklist, you can optimize your procurement strategy and enhance the quality of your hummingbird feeding solutions.

Step 1: Understand Regional Climate Variations

Climate plays a significant role in nectar spoilage. In warmer or humid regions, nectar should be changed every 1-2 days, while cooler climates may allow for a 2-4 day interval. Understanding these variations will help you establish appropriate procurement schedules and ensure the best practices for bird health.

Step 2: Evaluate Nectar Composition

The quality of nectar is paramount. Look for suppliers that provide nectar free of artificial dyes and additives. A natural nectar mix, typically a 4:1 water-to-sugar ratio, is ideal. This not only mimics natural flower nectar but also promotes the well-being of hummingbirds.

Step 3: Assess Feeder Design and Ease of Maintenance

Select feeders that are easy to clean and refill. Complex designs can lead to mold and bacteria build-up, compromising nectar quality. Ensure that the feeders have removable parts and are dishwasher-safe for efficient cleaning. Look for features like wide openings for easy access.

Step 4: Verify Supplier Certifications and Quality Standards

Before finalizing a supplier, confirm that they adhere to industry standards for food safety and quality. Request documentation that demonstrates compliance with local regulations, especially if you are importing products. This step is vital to avoid health risks associated with contaminated nectar.

Step 5: Check for Customer Support and Resources

A reliable supplier should offer robust customer support and educational resources. Inquire about guidance on feeder maintenance and best practices for nectar changes. A supplier that provides ongoing support can help you troubleshoot issues and optimize your hummingbird feeding programs.

Step 6: Inquire About Volume Discounts and Shipping Options

When sourcing feeders, consider your purchasing volume. Many suppliers offer discounts for bulk orders, which can significantly reduce costs. Additionally, evaluate shipping options to ensure timely delivery, especially if you are operating in regions with longer shipping times.

Step 7: Request Samples for Quality Assessment

Before making a large order, request samples of both the feeders and the nectar. This allows you to assess the quality firsthand and ensure that the products meet your standards. Testing the products in your own environment can provide valuable insights into their effectiveness and durability.

By following this checklist, B2B buyers can strategically navigate the procurement of hummingbird feeders and nectar, ensuring that they not only attract these beautiful birds but also contribute to their health and well-being.

Comprehensive Cost and Pricing Analysis for how often should i change hummingbird feeder Sourcing

When considering the sourcing of hummingbird feeders and their nectar change frequency, B2B buyers must navigate a multifaceted cost structure that impacts pricing. Understanding these components can help businesses make informed purchasing decisions.

What Are the Key Cost Components in Hummingbird Feeder Sourcing?

-

Materials: The primary materials for hummingbird feeders include durable plastics or glass for the feeder body, metal for the hanging components, and cotton or nylon for cleaning brushes. High-quality materials may incur a higher initial cost but can enhance durability and reduce replacement frequency.

-

Labor: Labor costs encompass the wages paid to workers involved in manufacturing, assembling, and packaging the feeders. These costs can vary significantly by region, reflecting local wage standards and labor laws, which is particularly relevant for international buyers.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can lower overhead costs, potentially impacting the final price.

-

Tooling: The initial investment in molds and tools for feeder production can be substantial. For custom designs or specifications, these costs might be amortized over a smaller production volume, leading to higher unit costs.

-

Quality Control (QC): Ensuring that feeders meet safety and quality standards involves costs related to testing and inspections. International certifications may be required for certain markets, adding to the overall expense.

-

Logistics: Shipping costs are influenced by distance, mode of transport, and the chosen Incoterms. For buyers in Africa or South America, understanding shipping logistics is crucial, as it can significantly affect total costs.

-

Margin: Suppliers typically build a profit margin into the final price, which can vary based on market demand, competition, and perceived value. Understanding supplier pricing strategies is essential for negotiation.

How Do Price Influencers Affect Hummingbird Feeder Costs?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider potential savings when negotiating bulk purchases.

-

Specifications and Customization: Customized designs or features can increase production complexity and costs. Buyers should weigh the benefits of customization against its impact on price.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly or food-safe) can lead to increased costs but may also justify a premium price due to enhanced durability and safety.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their perceived value, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding the terms of shipping is crucial for international buyers. Different Incoterms (like FOB, CIF) can affect who bears the cost of shipping and risk, influencing overall pricing strategies.

What Are Essential Tips for International B2B Buyers?

-

Negotiation: Engage in negotiations with suppliers to explore pricing flexibility, especially for bulk orders. Establishing a good relationship can lead to better terms and discounts.

-

Cost-Efficiency: Evaluate the total cost of ownership, which includes purchase price, shipping, and potential replacement costs due to lower-quality products. Opting for higher-quality feeders may lead to long-term savings.

-

Pricing Nuances for Different Markets: Understand regional pricing strategies. For instance, buyers from Nigeria or Saudi Arabia may encounter different market dynamics, affecting supply chain costs and pricing structures.

-

Research and Comparison: Conduct thorough market research to compare prices and suppliers. This can provide leverage in negotiations and help identify the best value offerings.

Disclaimer for Indicative Prices

Prices for hummingbird feeders and associated supplies can fluctuate based on market demand, material costs, and regional economic conditions. It is recommended that buyers seek current quotes from multiple suppliers to ensure they receive competitive pricing.

Alternatives Analysis: Comparing how often should i change hummingbird feeder With Other Solutions

In the quest for optimal hummingbird feeding practices, various alternatives exist to the common method of regularly changing hummingbird feeders. Understanding these alternatives can provide B2B buyers with insights into the most effective and efficient solutions for maintaining hummingbird health and enhancing the customer experience. Below, we compare the traditional practice of changing hummingbird feeder nectar with two alternative solutions: using automatic hummingbird feeders and employing nectar dispensing technology.

| Comparison Aspect | How Often Should I Change Hummingbird Feeder | Automatic Hummingbird Feeder | Nectar Dispensing Technology |

|---|---|---|---|

| Performance | Requires changing every 2-4 days, more in hot weather | Consistent supply of fresh nectar, minimal human intervention | Precise control of nectar quantity, customizable feeding intervals |

| Cost | Low initial investment; ongoing costs for nectar | Moderate initial investment; low maintenance costs | Higher initial investment; potential savings on nectar over time |

| Ease of Implementation | Simple to implement but labor-intensive | Easy to set up, requires some monitoring | Requires technical setup and calibration |

| Maintenance | Requires regular cleaning and refilling | Low maintenance; occasional cleaning needed | Minimal maintenance; needs occasional refilling |

| Best Use Case | Ideal for small-scale or casual bird watchers | Best for busy environments or where frequent changes are impractical | Suited for commercial or research settings needing precise control |

What Are the Pros and Cons of Using an Automatic Hummingbird Feeder?

Automatic hummingbird feeders are designed to dispense nectar at set intervals, ensuring a consistent supply for the birds. The primary advantage of this system is its convenience; once set up, it requires little oversight. This is particularly beneficial for businesses or organizations that may not have staff available to change the nectar regularly. However, the initial investment can be higher than traditional feeders, and they may require occasional technical adjustments to ensure proper function.

How Does Nectar Dispensing Technology Compare?

Nectar dispensing technology takes automation a step further by allowing for precise control over the amount and timing of nectar dispensed. This method is particularly advantageous in commercial settings, such as wildlife parks or research facilities, where monitoring bird activity and health is critical. While this technology can lead to significant savings on nectar in the long run due to reduced waste, it typically requires a higher initial investment and more complex setup, making it less feasible for casual bird watchers.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the best solution for hummingbird feeding, B2B buyers should consider their specific operational needs and budget constraints. For organizations with limited resources or those looking for a straightforward approach, regularly changing hummingbird feeders remains a reliable choice. Conversely, for businesses seeking efficiency and consistency, automatic feeders or advanced nectar dispensing technology may provide greater long-term value. Assessing factors such as performance, cost, and maintenance will guide buyers to the solution that best aligns with their objectives and enhances their overall hummingbird feeding strategy.

Illustrative image related to how often should i change hummingbird feeder

Essential Technical Properties and Trade Terminology for how often should i change hummingbird feeder

What Are the Essential Technical Properties for Hummingbird Feeders?

When considering the frequency of changing hummingbird feeders, several technical properties of the feeders and nectar play a pivotal role in ensuring optimal usage. Below are critical specifications to keep in mind:

-

Material Grade

Hummingbird feeders are typically made from materials like glass, plastic, or metal. The material grade affects durability, weather resistance, and ease of cleaning. For B2B buyers, sourcing feeders made from high-grade, non-toxic materials is essential to ensure longevity and safety for birds. -

Nectar Capacity

The nectar capacity of a feeder can range from a few ounces to over a quart. This specification impacts how often the nectar needs to be changed. A larger capacity feeder may require less frequent refills, which can be crucial for businesses focusing on ease of maintenance and operational efficiency. -

Feeding Port Design

The design and number of feeding ports influence the accessibility for hummingbirds and the potential for spoilage. More feeding ports can accommodate more birds, but they also require careful design to prevent nectar from leaking. Understanding this design can help B2B buyers choose feeders that maximize bird visits while minimizing waste. -

Weather Resistance

Feeders should be designed to withstand various weather conditions, including UV rays and moisture. This property is vital for buyers in diverse climates, ensuring that the products remain functional and aesthetically pleasing over time. Investing in weather-resistant products reduces replacement costs and enhances customer satisfaction. -

Ease of Cleaning

The design should facilitate easy disassembly and cleaning, which is crucial for maintaining fresh nectar. A feeder that is difficult to clean can lead to mold growth and health risks for birds. B2B buyers should prioritize feeders that offer straightforward maintenance solutions, as this can significantly influence customer retention. -

Color and Attraction Features

The use of colors and shapes in feeder design can attract hummingbirds more effectively. Feeders often incorporate bright colors or specific shapes to entice these birds. Understanding these features can help businesses select products that enhance bird visibility and engagement.

What Are Common Trade Terms Related to Hummingbird Feeders?

Familiarity with industry terminology can streamline transactions and improve communication between suppliers and buyers. Here are essential trade terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hummingbird feeders, an OEM might produce feeders that are branded by various retailers. Understanding OEM relationships can help B2B buyers identify potential sourcing options. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For hummingbird feeders, knowing the MOQ is critical for inventory management and financial planning. Businesses should negotiate MOQs that align with their sales forecasts to optimize stock levels. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. B2B buyers can use RFQs to gather pricing information for hummingbird feeders, facilitating comparison shopping and better negotiation outcomes. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers sourcing hummingbird feeders from global suppliers, as they dictate shipping responsibilities and costs. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. In the context of hummingbird feeders, understanding lead times helps businesses plan their inventory and ensure they meet customer demand without delays. -

SKU (Stock Keeping Unit)

An SKU is a unique identifier for each product variant. For hummingbird feeders, SKUs help businesses track inventory and sales data efficiently. This tracking is essential for managing product lines and ensuring that popular items remain in stock.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their product offerings and operational efficiency in the hummingbird feeder market.

Navigating Market Dynamics and Sourcing Trends in the how often should i change hummingbird feeder Sector

What Are the Current Market Dynamics Influencing Hummingbird Feeder Nectar Replacement?

The global market for hummingbird feeders and related products is increasingly driven by a growing interest in birdwatching and wildlife preservation. This trend is particularly notable among international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. In these markets, urbanization and environmental awareness are fostering a demand for backyard birdfeeding solutions. As consumers become more conscious of their ecological footprints, they are increasingly seeking products that promote sustainable interactions with nature.

Illustrative image related to how often should i change hummingbird feeder

Emerging technologies, such as app-based monitoring systems and smart feeders, are becoming more prevalent, allowing users to track nectar consumption and feeder cleanliness. This technology not only enhances user experience but also supports optimal feeding practices by reminding users when to change nectar. Additionally, as e-commerce platforms expand, B2B buyers are leveraging these technologies to streamline sourcing processes, making it easier to acquire high-quality products that meet customer demands.

Furthermore, climatic conditions play a critical role in determining nectar replacement schedules. For instance, warmer regions may necessitate more frequent changes due to faster spoilage rates, prompting suppliers to educate their customers on best practices tailored to specific environments. This knowledge empowers businesses to offer localized solutions, enhancing customer satisfaction and loyalty.

How Is Sustainability Influencing the Sourcing of Hummingbird Feeders?

Sustainability is becoming a cornerstone of business operations in the hummingbird feeder sector. The environmental impact of sourcing materials is a growing concern, prompting companies to prioritize ethical sourcing practices. B2B buyers are increasingly interested in products that are made from recycled or eco-friendly materials, as these options reduce waste and minimize harm to ecosystems.

Moreover, certifications for environmentally friendly practices are gaining traction. Businesses that can demonstrate compliance with sustainability standards, such as those set by organizations like the Forest Stewardship Council (FSC) or Global Recycled Standard (GRS), are more likely to attract discerning buyers. This shift not only enhances brand reputation but also aligns with the values of a consumer base that is progressively prioritizing sustainability.

Illustrative image related to how often should i change hummingbird feeder

In addition, ethical supply chains are essential for fostering trust and transparency in transactions. By ensuring that materials are sourced responsibly, companies can mitigate risks related to environmental degradation and labor exploitation. This is particularly important in regions where regulatory oversight may be less stringent, making it imperative for international buyers to verify the ethical standards of their suppliers.

What Historical Context Is Relevant to Hummingbird Feeder Practices?

The evolution of hummingbird feeders can be traced back to the early 20th century when they were primarily made from glass and metal. Initially designed for aesthetic appeal, these feeders lacked the functionality that modern consumers expect today. As interest in birdwatching surged in the latter half of the century, manufacturers began innovating to enhance feeder efficiency and ease of use.

Today, the emphasis is not only on aesthetics but also on functionality, with advancements in materials and design that facilitate easier cleaning and maintenance. The contemporary focus on how often to change nectar has led to a more informed consumer base, with suppliers now providing guidelines based on environmental conditions. This historical progression underscores the importance of adapting to consumer needs and market dynamics, which remains crucial for B2B buyers looking to thrive in this sector.

Conclusion

Navigating the hummingbird feeder market involves understanding the intricate dynamics of consumer preferences, technological advancements, and sustainability imperatives. By focusing on these areas, international B2B buyers can position themselves strategically, ensuring they meet the demands of a growing and conscientious customer base.

Frequently Asked Questions (FAQs) for B2B Buyers of how often should i change hummingbird feeder

-

How often should I change the nectar in hummingbird feeders?

Changing the nectar in hummingbird feeders is crucial for attracting these birds and ensuring their health. In warmer climates, it is recommended to change the nectar every 1 to 2 days, while in cooler temperatures, it can be changed every 2 to 4 days. Regularly inspecting the nectar for signs of spoilage, such as cloudiness or mold, will help maintain the feeder’s appeal to hummingbirds. This practice not only supports their well-being but also encourages repeat visits, enhancing customer satisfaction for businesses that sell these products. -

What are the best types of hummingbird feeders for commercial use?

For commercial use, feeders that are easy to clean, durable, and designed to minimize insect intrusion are ideal. Look for models made from high-quality materials such as glass or robust plastics that can withstand various weather conditions. Additionally, feeders with larger nectar capacities reduce the frequency of refilling, making them more efficient for businesses. It’s also beneficial to choose feeders with a design that allows for easy monitoring of nectar levels, ensuring optimal freshness. -

How can I ensure the quality of the hummingbird feeders I source?

To ensure the quality of hummingbird feeders, it is essential to conduct thorough supplier vetting. Request samples to assess the materials and craftsmanship firsthand. Look for suppliers with certifications or quality assurance processes in place. Additionally, checking customer reviews and testimonials can provide insights into the reliability of the product. Establishing a clear quality control protocol upon receiving shipments will further safeguard your investment. -

What customization options are available for hummingbird feeders?

Many suppliers offer customization options for hummingbird feeders, such as branding, colors, and specific designs tailored to your market. When sourcing, inquire about the minimum order quantities (MOQ) for customized products, as this can vary significantly between manufacturers. Customization can help your brand stand out in competitive markets, so consider how these options align with your target audience’s preferences. -

What payment terms should I expect when sourcing hummingbird feeders internationally?

Payment terms can vary widely depending on the supplier and region. Common terms include upfront payment, a deposit with the balance upon delivery, or net payment terms (e.g., 30, 60, or 90 days). When negotiating, ensure that the terms are favorable for your cash flow and that they align with your business operations. Consider using secure payment methods that offer buyer protection, especially when dealing with international transactions. -

How do I handle logistics and shipping for hummingbird feeders?

Effective logistics management is crucial when sourcing hummingbird feeders internationally. Collaborate with suppliers who have experience in shipping to your region and can provide reliable freight options. Understand the shipping costs, estimated delivery times, and customs duties involved in the process. Additionally, establishing a clear communication channel with your supplier will help address any shipping issues promptly, ensuring that your inventory remains consistent. -

What are the environmental considerations when sourcing hummingbird feeders?

Sustainability is becoming increasingly important in international trade. When sourcing hummingbird feeders, consider suppliers that use eco-friendly materials and sustainable manufacturing practices. Inquire about the recyclability of the products and packaging. Aligning your sourcing strategy with environmental responsibility can enhance your brand’s reputation and appeal to environmentally conscious consumers. -

How can I differentiate my hummingbird feeder offerings in the market?

Differentiating your hummingbird feeder offerings can be achieved through innovative designs, unique features, and superior customer service. Consider offering feeders with specialized features, such as insect-resistant designs, easy-clean mechanisms, or integrated bird-friendly enhancements. Additionally, providing exceptional customer support and educational resources about hummingbird care can create a loyal customer base and distinguish your brand from competitors in the market.

Top 2 How Often Should I Change Hummingbird Feeder Manufacturers & Suppliers List

1. Hummingbird Feeders – Maintenance Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Change sugar-water in hummingbird feeders every day when temperatures exceed 80 degrees Fahrenheit to prevent mold and bacteria growth. In cooler weather, change it every two days. It’s recommended to fill feeders with only a small amount if there are few birds, and to keep feeders clean for the health of the hummingbirds.

2. Facebook – Feeder Maintenance Guidelines

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Feeder Maintenance Guidelines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how often should i change hummingbird feeder

In conclusion, the frequency of changing hummingbird feeder nectar is a vital aspect for ensuring the health and attraction of these beautiful birds. For international B2B buyers, understanding the nuances of nectar freshness—particularly in varying climates—is essential. The consensus among experts suggests changing nectar every 2 to 4 days, with more frequent changes in warmer, humid conditions. This practice not only prevents spoilage but also encourages consistent visits from hummingbirds, enhancing the overall birdwatching experience.

Strategic sourcing plays a crucial role in optimizing your supply chain for bird feeding products. By partnering with reliable suppliers who prioritize quality ingredients for nectar and offer durable feeders, businesses can meet the demands of their customers while fostering a sustainable approach to bird feeding.

As you navigate the international market, particularly in regions like Africa, South America, the Middle East, and Europe, consider the long-term benefits of sourcing high-quality products that support avian health. Investing in superior hummingbird feeders and nectar will not only satisfy your customers but also position your business as a leader in the birding community. Embrace this opportunity to enrich the lives of both birds and bird enthusiasts alike.

Illustrative image related to how often should i change hummingbird feeder

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.