Introduction: Navigating the Global Market for automatic dog feeders for outside

In the ever-evolving landscape of pet care, the demand for efficient solutions is on the rise, particularly in the realm of automatic dog feeders for outside. As international B2B buyers seek to address the challenges of reliable pet feeding in diverse environments, the importance of sourcing high-quality, durable products cannot be overstated. This guide serves as a comprehensive resource, offering insights into various types of outdoor automatic dog feeders, their applications, supplier vetting processes, and cost considerations.

Navigating the global market can be daunting, especially for businesses in regions like Africa, South America, the Middle East, and Europe, including emerging markets such as Vietnam and Saudi Arabia. This guide aims to empower decision-makers by providing actionable information that enhances their purchasing strategies. By understanding the specifications, installation requirements, and potential challenges associated with outdoor feeders, buyers can make informed decisions that align with their operational needs and customer expectations.

Furthermore, we will explore the advantages of integrating these feeders into existing pet care services, helping businesses to enhance their offerings and improve customer satisfaction. With this guide, B2B buyers will not only gain clarity on product options but also develop a strategic approach to sourcing that ensures both quality and value in their investments.

Table Of Contents

- Top 3 Automatic Dog Feeders For Outside Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automatic dog feeders for outside

- Understanding automatic dog feeders for outside Types and Variations

- Key Industrial Applications of automatic dog feeders for outside

- 3 Common User Pain Points for ‘automatic dog feeders for outside’ & Their Solutions

- Strategic Material Selection Guide for automatic dog feeders for outside

- In-depth Look: Manufacturing Processes and Quality Assurance for automatic dog feeders for outside

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic dog feeders for outside’

- Comprehensive Cost and Pricing Analysis for automatic dog feeders for outside Sourcing

- Alternatives Analysis: Comparing automatic dog feeders for outside With Other Solutions

- Essential Technical Properties and Trade Terminology for automatic dog feeders for outside

- Navigating Market Dynamics and Sourcing Trends in the automatic dog feeders for outside Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automatic dog feeders for outside

- Strategic Sourcing Conclusion and Outlook for automatic dog feeders for outside

- Important Disclaimer & Terms of Use

Understanding automatic dog feeders for outside Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gravity Feeders | Simple design that uses gravity to dispense food; no power required. | Small pet stores, rural distributors | Pros: Low maintenance, cost-effective. Cons: Limited portion control, may attract pests. |

| Electronic Programmable Feeders | Allows for precise feeding schedules and portion control; often includes digital timers. | Veterinary clinics, dog training centers | Pros: Customizable feeding, reduces overfeeding. Cons: Higher upfront cost, requires power. |

| Smart Feeders | Integrates with apps for remote feeding and monitoring; often includes camera features. | Pet tech retailers, e-commerce platforms | Pros: Remote access, monitoring capabilities. Cons: Reliant on Wi-Fi, can be expensive. |

| Battery-Operated Feeders | Operates on batteries, suitable for locations without power access. | Outdoor pet care services, shelters | Pros: Flexible placement, no power source needed. Cons: Battery replacement required, may have lower capacity. |

| Wall-Mounted Feeders | Fixed installation that saves space and provides stability; often weather-resistant. | Pet boarding facilities, animal shelters | Pros: Space-efficient, durable. Cons: Installation required, less portable. |

What Are the Characteristics of Gravity Feeders for Outdoor Use?

Gravity feeders are a straightforward solution for outdoor feeding, relying on gravity to dispense food. They are typically made from durable materials to withstand outdoor elements. These feeders are best suited for smaller operations, such as local pet stores or rural distributors. B2B buyers should consider the low maintenance and cost-effectiveness of gravity feeders, but they also need to be aware of the limited portion control and potential for pest attraction.

How Do Electronic Programmable Feeders Enhance Feeding Precision?

Electronic programmable feeders offer enhanced control over feeding schedules and portion sizes, often equipped with digital timers. This type is particularly beneficial for veterinary clinics and dog training centers, where precise feeding is crucial for pet health. When purchasing, B2B buyers should evaluate the upfront investment against the long-term benefits of reduced overfeeding and customizable feeding options, although these feeders require a power source and may have higher initial costs.

Illustrative image related to automatic dog feeders for outside

What Advantages Do Smart Feeders Provide for Pet Monitoring?

Smart feeders represent the cutting edge of pet feeding technology, integrating with mobile applications for remote feeding and monitoring. This innovation is particularly appealing to pet tech retailers and e-commerce platforms. B2B buyers should prioritize the convenience of remote access and monitoring capabilities, but they must also consider the reliance on Wi-Fi and the higher price point associated with these advanced models.

Why Are Battery-Operated Feeders Ideal for Remote Locations?

Battery-operated feeders are designed for flexibility, allowing placement in areas without direct power access. This makes them suitable for outdoor pet care services and shelters. When considering these feeders, B2B buyers should appreciate their portability and ease of installation, while also being mindful of the need for regular battery replacements and potentially lower food capacity.

How Do Wall-Mounted Feeders Benefit Commercial Operations?

Wall-mounted feeders provide a stable and space-efficient solution for feeding pets outdoors. Their durability makes them a great choice for pet boarding facilities and animal shelters. Buyers should consider the benefits of a fixed installation that minimizes the risk of tipping or damage, although installation may be required, making them less portable than other options.

Illustrative image related to automatic dog feeders for outside

Key Industrial Applications of automatic dog feeders for outside

| Industry/Sector | Specific Application of Automatic Dog Feeders for Outside | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Livestock and Working Dog Feeding | Ensures timely feeding, reducing labor costs and improving animal health | Durability for outdoor conditions, capacity for large feed amounts |

| Animal Shelters | Feeding Stray and Rescue Dogs | Automates feeding processes, allowing staff to focus on care rather than feeding | Weatherproof design, easy maintenance, and safety features |

| Veterinary Services | Outdoor Feeding for Therapy and Service Dogs | Supports the health and training of service animals, enhancing patient care | Programmable feeding schedules, robust construction, and safety features |

| Pet Retailers | Display and Demo Units for Outdoor Feeders | Attracts customers with live demonstrations, driving sales | Aesthetic design, user-friendly operation, and reliable performance |

| Landscaping and Facilities Management | Feeding Dogs in Parks or Outdoor Spaces | Promotes responsible pet ownership and enhances community spaces | Easy installation, low maintenance, and compatibility with various kibble sizes |

How Are Automatic Dog Feeders Used in Agriculture for Livestock and Working Dogs?

In agricultural settings, automatic dog feeders serve to streamline the feeding process for working dogs and livestock guardians. These feeders can be programmed to dispense food at specific intervals, ensuring that animals receive proper nutrition without requiring constant human supervision. This automation not only reduces labor costs but also helps maintain the health of the animals by providing consistent feeding schedules. Buyers in this sector should prioritize feeders that are durable and capable of holding large quantities of feed to accommodate multiple animals.

What Role Do Automatic Dog Feeders Play in Animal Shelters?

Animal shelters utilize automatic dog feeders to care for stray and rescue dogs efficiently. By automating the feeding process, shelters can allocate their limited resources to other essential tasks, such as animal care and rehabilitation. The feeders can be programmed to dispense food at designated times, ensuring that every dog receives adequate nutrition. When sourcing these feeders, shelters should look for models that are weatherproof and easy to maintain, as they may be exposed to outdoor elements.

How Do Veterinary Services Benefit from Outdoor Feeding Solutions?

Veterinary services often employ automatic dog feeders for therapy and service dogs, facilitating their feeding while they undergo training or treatment. These feeders help maintain a structured feeding regimen, which is critical for the health and performance of service animals. Furthermore, veterinarians can monitor food intake to ensure proper nutrition. Buyers in this sector should consider feeders with programmable schedules and robust construction to withstand frequent use.

How Can Pet Retailers Use Automatic Feeders as Display Units?

Pet retailers can leverage automatic dog feeders as display and demo units to attract customers. By showcasing how these feeders work, retailers can drive sales and enhance customer engagement. The visual demonstration of feeding in real-time can highlight the convenience and benefits of automatic feeders. Retailers should focus on sourcing aesthetically pleasing designs that are user-friendly and demonstrate reliable performance to entice potential buyers.

What Are the Advantages of Automatic Dog Feeders in Landscaping and Facilities Management?

In parks and outdoor spaces managed by landscaping and facilities management companies, automatic dog feeders can play a role in promoting responsible pet ownership. By providing a reliable feeding solution, these feeders encourage dog owners to maintain the cleanliness of public areas while ensuring their pets are well-fed. Buyers in this sector should seek feeders that are easy to install, require minimal maintenance, and can accommodate various kibble sizes to cater to different dog breeds.

Illustrative image related to automatic dog feeders for outside

3 Common User Pain Points for ‘automatic dog feeders for outside’ & Their Solutions

Scenario 1: Weather-Resistant Design Challenges

The Problem: Many B2B buyers face difficulties in sourcing automatic dog feeders that can withstand harsh outdoor conditions. In regions with extreme temperatures or heavy rainfall, traditional feeders may fail, leading to food spoilage, feeder damage, or disrupted feeding schedules. This can be particularly challenging for businesses that manage outdoor dog parks, shelters, or boarding facilities, where consistent feeding is crucial for pet health and well-being. Buyers often feel frustrated when products marketed as “outdoor” do not deliver on durability, resulting in additional costs for replacements and maintenance.

The Solution: To address this concern, B2B buyers should prioritize sourcing feeders that are specifically designed for outdoor use, focusing on materials that offer weather resistance. Look for feeders constructed from heavy-duty, rust-resistant materials like stainless steel or high-grade plastic that can withstand UV exposure and moisture. Additionally, consider feeders with sealed components and weatherproof enclosures to prevent water ingress. It is also beneficial to consult manufacturers about their testing protocols for outdoor durability. Buyers should seek products that come with warranties or guarantees to ensure long-term reliability, mitigating the risk of frequent replacements.

Scenario 2: Difficulty in Portion Control

The Problem: Another common pain point is ensuring accurate portion control. Many automatic feeders struggle with delivering consistent portion sizes, which can lead to overfeeding or underfeeding. For businesses that rely on precise feeding for health management—such as veterinary clinics or shelters—this inconsistency can result in nutritional imbalances. Moreover, the variation in kibble size and shape can exacerbate the issue, leading to further complications in feeding routines.

The Solution: B2B buyers should look for automatic feeders equipped with adjustable portion settings and those that utilize high-quality dispensing mechanisms. Seek models that allow for customization of portion sizes based on the specific dietary needs of different breeds and sizes of dogs. Additionally, investing in feeders that have a built-in scale for real-time weight measurement can enhance accuracy. When selecting a feeder, it is prudent to conduct tests with the specific kibble types used in your operations to ensure compatibility and functionality. Regularly calibrating the feeders according to manufacturer guidelines can also help maintain consistent portion sizes.

Scenario 3: Animal Intrusion and Feeder Security

The Problem: Outdoor feeders are often susceptible to intrusions by other animals, such as raccoons or birds, which can lead to food wastage and potential health risks for the dogs being fed. This challenge is especially prevalent in urban or semi-rural areas where wildlife is abundant. B2B buyers managing outdoor feeding solutions may find that their investments are undermined when feeders are raided, resulting in costly replacements and increased labor for cleanup.

Illustrative image related to automatic dog feeders for outside

The Solution: To mitigate this issue, B2B buyers should consider feeders that come with protective features such as locking mechanisms or bait-resistant designs. Additionally, feeders that are elevated or equipped with protective barriers can deter unwanted animals from accessing the food. Buyers should also explore custom installation options that allow for integration into existing structures, such as dog houses or fenced areas, to enhance security. Engaging with suppliers who offer advice on optimal placement and installation can further reduce the risk of intrusion. Regularly inspecting and maintaining the feeders will ensure that any vulnerabilities are addressed promptly, preserving the integrity of the feeding solution.

Strategic Material Selection Guide for automatic dog feeders for outside

What Are the Key Materials for Automatic Dog Feeders Designed for Outdoor Use?

When selecting materials for automatic dog feeders intended for outdoor use, it is essential to consider properties that ensure durability, functionality, and compliance with international standards. Here, we analyze four common materials: stainless steel, high-density polyethylene (HDPE), aluminum, and galvanized steel.

How Does Stainless Steel Perform in Outdoor Dog Feeders?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it an ideal choice for outdoor applications. It can withstand a wide range of temperatures and is less likely to warp or crack under pressure. However, the cost of stainless steel can be significantly higher than other materials, which may impact budget considerations for B2B buyers.

Pros: High durability, excellent corrosion resistance, and easy to clean.

Cons: Higher cost and potential for scratching, which can harbor bacteria.

Impact on Application: Suitable for all types of dog food, including kibble and wet food, but may require additional coatings to enhance scratch resistance.

Considerations for International Buyers: Compliance with food safety standards (like FDA or EU regulations) is crucial, as is awareness of local market preferences for aesthetics and pricing.

What Are the Benefits of High-Density Polyethylene (HDPE)?

HDPE is a lightweight, cost-effective material that offers good impact resistance and is resistant to moisture. It is less prone to cracking and fading when exposed to UV light, making it suitable for outdoor environments. However, HDPE may not withstand extreme temperatures as well as metals, which could be a concern in regions with fluctuating climates.

Illustrative image related to automatic dog feeders for outside

Pros: Lightweight, cost-effective, and resistant to moisture and UV rays.

Cons: Less durable than metals and may deform under high heat.

Impact on Application: Ideal for kibble feeders but may struggle with wet food applications due to potential degradation.

Considerations for International Buyers: Look for compliance with local recycling regulations, as HDPE is highly recyclable, which may appeal to environmentally conscious markets.

Why Choose Aluminum for Outdoor Dog Feeders?

Aluminum is another popular material due to its lightweight nature and resistance to corrosion. It is relatively inexpensive compared to stainless steel and can be anodized for additional protection against the elements. However, aluminum can be prone to dents and scratches, which may affect its longevity.

Pros: Lightweight, cost-effective, and corrosion-resistant with potential for anodization.

Cons: Prone to dents and scratches, which can compromise its integrity over time.

Impact on Application: Suitable for dry dog food but may require additional coatings to enhance durability against outdoor conditions.

Considerations for International Buyers: Ensure compliance with local standards for materials used in pet products, as some regions may have specific requirements.

What Advantages Does Galvanized Steel Offer for Automatic Feeders?

Galvanized steel is coated with a layer of zinc to prevent rusting, making it a robust option for outdoor feeders. It is highly durable and can withstand harsh weather conditions. However, the weight of galvanized steel can be a drawback, making installation more complex and potentially leading to higher shipping costs.

Pros: Extremely durable, rust-resistant, and suitable for a variety of climates.

Cons: Heavier than other materials, which can complicate installation and shipping.

Impact on Application: Excellent for all types of dog food, but may require additional insulation or coating to prevent condensation inside the feeder.

Considerations for International Buyers: Be aware of local standards regarding the use of galvanized materials, as some regions may have restrictions on zinc exposure.

Illustrative image related to automatic dog feeders for outside

Summary Table of Material Selection for Outdoor Automatic Dog Feeders

| Material | Typical Use Case for automatic dog feeders for outside | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-end feeders for all types of dog food | Exceptional durability and corrosion resistance | Higher cost and potential for scratches | High |

| High-Density Polyethylene (HDPE) | Budget-friendly feeders for dry kibble | Lightweight and moisture-resistant | Less durable and may deform in heat | Low |

| Aluminum | Lightweight feeders for dry food | Cost-effective and corrosion-resistant | Prone to dents and scratches | Medium |

| Galvanized Steel | Heavy-duty feeders for all food types | Extremely durable and rust-resistant | Heavier, complicating installation | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to invest in automatic dog feeders designed for outdoor use, ensuring that they can make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic dog feeders for outside

What Are the Key Stages in the Manufacturing Process of Automatic Dog Feeders for Outdoor Use?

Manufacturing automatic dog feeders designed for outdoor environments involves several critical stages that ensure the final product is durable, efficient, and reliable. The process typically includes material preparation, forming, assembly, and finishing.

-

Material Preparation: The selection of materials is vital for outdoor dog feeders due to exposure to the elements. Common materials include high-density polyethylene (HDPE) for the feeder body, stainless steel for food contact surfaces, and weather-resistant plastics for electronic components. Suppliers must ensure that these materials meet international standards for safety and durability.

-

Forming: This stage involves shaping the prepared materials into the required parts. Techniques such as injection molding for plastic components and stamping for metal parts are commonly employed. Precision is crucial during this stage to ensure all components fit together seamlessly, which is essential for the feeder’s functionality and longevity.

-

Assembly: Once the individual components are formed, they are brought together in an assembly line. Automated processes often handle the initial assembly, while quality control personnel check for proper fit and function. Key features such as timers and power supply connections are integrated at this stage, ensuring that the feeders can operate efficiently in outdoor conditions.

-

Finishing: The finishing stage includes painting or coating the feeders to enhance their weather resistance and aesthetic appeal. High-quality paints and coatings are applied to prevent rust, corrosion, and UV damage. This stage may also include the installation of additional features, such as chute covers or anti-pest measures, which are critical for outdoor use.

How Is Quality Control Implemented in Manufacturing Automatic Dog Feeders?

Quality control (QC) is paramount in ensuring that automatic dog feeders meet both safety and performance standards. Manufacturers typically adhere to international standards such as ISO 9001, which outlines a framework for quality management systems.

-

International Standards Compliance: For B2B buyers, understanding a manufacturer’s compliance with standards like ISO 9001, CE marking, and API specifications is essential. These certifications indicate that the products have been tested for quality and safety, providing assurance to buyers regarding their reliability.

-

Quality Control Checkpoints: Manufacturers implement several QC checkpoints throughout the production process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, processes are monitored to catch defects early. This includes checks on the dimensions and functionality of individual components.

– Final Quality Control (FQC): Finished products undergo rigorous testing to ensure they function as intended. This may include operational tests, stress tests, and safety evaluations. -

Common Testing Methods: Various testing methods are employed to verify the quality of the feeders. These may include:

– Performance Testing: Assessing the feeder’s dispensing accuracy and reliability under different environmental conditions.

– Durability Testing: Subjecting the feeders to extreme temperatures and weather conditions to evaluate their resilience.

– Safety Testing: Ensuring that all electrical components comply with safety standards to prevent hazards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, due diligence in verifying supplier QC practices is essential.

-

Supplier Audits: Conducting audits of potential suppliers provides insights into their manufacturing processes and QC measures. Buyers should look for documented evidence of compliance with international standards, including QC protocols and past audit results.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can help buyers assess the quality of production. These reports should outline the methods used, results from testing phases, and any corrective actions taken for past defects.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process. This is particularly beneficial for buyers unfamiliar with the supplier’s practices or those operating in regions with different regulatory standards.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers face unique challenges when sourcing automatic dog feeders, particularly regarding quality assurance and compliance with local regulations.

-

Regulatory Nuances: Different regions may have varying regulations concerning pet products, including specific material safety standards. Buyers should familiarize themselves with these requirements to ensure that products comply with local laws.

-

Logistics and Supply Chain Quality: The supply chain plays a crucial role in maintaining product quality. Buyers should evaluate not only the manufacturer but also the logistics providers involved in transporting the feeders. Delays or poor handling during shipping can compromise product integrity.

-

Cultural and Economic Factors: Understanding the cultural and economic contexts of suppliers in regions such as Vietnam and Saudi Arabia can influence quality. Factors such as labor practices, local material availability, and economic stability can affect manufacturing quality and consistency.

Conclusion: Ensuring Quality in Automatic Dog Feeders for Outdoor Use

By understanding the manufacturing processes and quality assurance protocols involved in the production of automatic dog feeders, B2B buyers can make informed purchasing decisions. Engaging with suppliers who prioritize quality control and adhere to international standards is essential for ensuring that products meet the demands of outdoor environments and provide reliable service to pet owners.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic dog feeders for outside’

In the competitive landscape of pet care products, sourcing automatic dog feeders for outdoor use requires a strategic approach. This guide provides a comprehensive checklist to assist B2B buyers in making informed purchasing decisions that align with their business needs and customer expectations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right automatic dog feeder for outdoor settings. Consider factors such as the feeder’s capacity, the type of food it can dispense, and its power requirements. For instance, assess whether the feeder will operate on standard voltage or if a low-voltage alternative is necessary, especially in regions with different electrical standards.

Step 2: Evaluate Durability and Weather Resistance

Given that these feeders will be used outdoors, durability and resistance to weather conditions are paramount. Look for materials that can withstand harsh weather, including rain, sun, and temperature fluctuations. Ensure the feeder has features like waterproof enclosures and rust-resistant components to guarantee longevity and reliable performance.

Step 3: Assess Portion Control Features

Effective portion control is essential for managing pet diets and preventing overfeeding. Examine the feeder’s mechanisms for portion sizing—some models allow for customizable settings to dispense food in specific quantities at scheduled times. This capability not only aids in maintaining pet health but also enhances customer satisfaction.

Illustrative image related to automatic dog feeders for outside

Step 4: Verify Supplier Certifications and Compliance

Before finalizing any purchase, confirm that suppliers meet relevant industry standards and certifications. Look for compliance with international safety regulations, especially if you’re sourcing from different countries. This step helps mitigate risks associated with quality and safety, ensuring that the products are suitable for your market.

Step 5: Request Samples and Conduct Testing

It’s prudent to request samples from potential suppliers to evaluate product quality firsthand. Testing the feeder in real-world conditions can provide insights into its functionality, ease of use, and maintenance requirements. Ensure that the feeder operates smoothly and meets your specifications before making a bulk order.

Step 6: Consider After-Sales Support and Warranty

A reliable after-sales support system is vital for addressing potential issues post-purchase. Inquire about warranty terms and the availability of replacement parts. A strong support system not only enhances product reliability but also builds trust with your customers, who may require assistance with setup or troubleshooting.

Step 7: Analyze Pricing and Shipping Logistics

Finally, conduct a thorough analysis of pricing structures and shipping logistics. Compare quotes from multiple suppliers to identify competitive pricing while considering shipping costs and timelines. Efficient logistics can significantly impact your bottom line, especially if you’re sourcing from international suppliers.

By following these steps, B2B buyers can confidently source automatic dog feeders designed for outdoor use, ensuring they meet market demands and customer expectations.

Illustrative image related to automatic dog feeders for outside

Comprehensive Cost and Pricing Analysis for automatic dog feeders for outside Sourcing

What Are the Key Cost Components for Automatic Dog Feeders?

When analyzing the cost structure of automatic dog feeders designed for outdoor use, several critical components contribute to the overall pricing.

-

Materials: The choice of materials directly impacts both cost and durability. Common materials include high-grade plastics, stainless steel, and weather-resistant components. Premium materials might incur higher costs but can result in longer-lasting products that withstand outdoor conditions.

-

Labor: Labor costs vary significantly based on the manufacturing location. Countries with lower labor costs, such as some regions in South America or Southeast Asia, can offer more competitive pricing. However, the level of craftsmanship and expertise required for producing high-quality feeders can also influence labor costs.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses. Manufacturing plants that optimize their processes can reduce overhead costs, allowing for more competitive pricing.

-

Tooling: The initial investment in molds and machinery for production can be substantial. These costs are typically amortized over the production run, impacting the unit price. Buyers should inquire about the tooling capabilities of potential suppliers to understand the scalability of production.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability, which is essential for outdoor feeders that need to function in various environments. Higher QC standards may lead to increased costs but can prevent costly returns and dissatisfaction.

-

Logistics: Transportation and warehousing costs are vital, especially for international buyers. Shipping methods, distances, and customs duties can significantly influence the final price.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. This margin can vary widely based on market competition and supplier positioning.

How Do Price Influencers Affect the Cost of Outdoor Dog Feeders?

Several factors can influence the pricing of automatic dog feeders, especially for B2B buyers looking to import these products.

-

Volume/MOQ: Bulk purchases often lead to significant discounts. Suppliers may have minimum order quantities (MOQ) that can affect pricing. Negotiating larger volumes can yield better per-unit pricing.

-

Specifications and Customization: Custom features, such as specific hopper sizes, feeding mechanisms, or branding, can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or safety standards) can raise costs but may be necessary for certain markets. Buyers should consider local regulations and consumer expectations when assessing these factors.

-

Supplier Factors: Supplier reputation, reliability, and service levels can affect pricing. Established suppliers may charge a premium for their experience and support.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can influence the final landed cost. Understanding these terms is crucial for accurate budgeting.

What Are the Best Negotiation Tips for B2B Buyers?

When sourcing automatic dog feeders for outdoor use, buyers should consider the following strategies to maximize cost-efficiency:

-

Research Market Prices: Understanding the prevailing market rates for similar products can empower buyers during negotiations.

-

Leverage Volume Discounts: If planning to purchase in bulk, clearly communicate this to suppliers to negotiate better rates.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also shipping, installation, maintenance, and potential return costs over time. A lower initial price may lead to higher long-term costs if the product is less durable.

-

Be Culturally Aware: Understanding cultural nuances can facilitate smoother negotiations, especially when dealing with suppliers from diverse regions like Africa, South America, or the Middle East.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can create competitive tension, leading to better pricing and terms.

Conclusion: Why Is Understanding Pricing Nuances Crucial for International B2B Buyers?

For international buyers, particularly those in emerging markets, being aware of pricing nuances is essential. Variability in local currencies, import duties, and shipping costs can significantly impact the overall expenditure. Therefore, conducting thorough due diligence and fostering strong supplier relationships will ultimately lead to more favorable procurement outcomes.

Disclaimer: Prices may vary based on supplier, location, and market conditions. Always confirm current pricing and terms before proceeding with orders.

Illustrative image related to automatic dog feeders for outside

Alternatives Analysis: Comparing automatic dog feeders for outside With Other Solutions

Introduction to Alternative Solutions for Outdoor Dog Feeding

In the realm of pet care, particularly for outdoor environments, automatic dog feeders present a convenient solution for ensuring pets receive their meals on time. However, several alternative methods exist that can also fulfill the need for feeding dogs outdoors. Understanding these alternatives allows B2B buyers to make informed decisions that align with their operational needs and budget constraints.

Comparison Table of Outdoor Dog Feeding Solutions

| Comparison Aspect | Automatic Dog Feeders For Outside | Gravity Feeders | Manual Feeding Solutions |

|---|---|---|---|

| Performance | High, programmable feeding times | Moderate, relies on gravity | Variable, dependent on human schedule |

| Cost | Moderate to high ($100 – $300) | Low to moderate ($20 – $100) | Minimal (cost of food only) |

| Ease of Implementation | Requires setup and power source | Simple installation, no power needed | Requires consistent human involvement |

| Maintenance | Moderate, occasional cleaning needed | Low, minimal upkeep | High, requires daily attention |

| Best Use Case | Ideal for busy households or kennels | Suitable for free-roaming dogs in yards | Best for small numbers of pets with regular human presence |

Detailed Breakdown of Alternatives

Gravity Feeders

Gravity feeders operate on a simple principle: food is dispensed by gravity into a bowl as the dog eats. They are straightforward to set up, requiring no power source or complex installation. This type of feeder is particularly cost-effective, often priced between $20 and $100. However, their performance can be inconsistent, as they do not allow for portion control or specific feeding times. They are best suited for environments where dogs have free access to food throughout the day, making them ideal for farms or households with multiple pets.

Manual Feeding Solutions

Manual feeding involves traditional feeding methods, where pet owners dispense food at scheduled times. This approach incurs minimal additional costs beyond the price of food itself, making it the most economical option. However, it requires a significant commitment of time and effort, as pet owners must be present to feed their dogs consistently. This method lacks the convenience and reliability of automatic feeders, especially for busy professionals or those managing multiple dogs. Manual feeding is best for small households or situations where pet owners can ensure timely feedings.

Illustrative image related to automatic dog feeders for outside

Conclusion: How to Choose the Right Outdoor Dog Feeding Solution

When selecting the best outdoor dog feeding solution, B2B buyers should evaluate their specific needs, including the number of dogs, feeding schedules, and budget constraints. Automatic dog feeders are excellent for those seeking convenience and precision, especially in busy kennels or shelters. Conversely, gravity feeders offer a budget-friendly option for environments where dogs can graze freely, while manual feeding suits smaller operations with dedicated human oversight. By assessing these factors, buyers can choose a solution that optimally meets their operational requirements and enhances pet care efficiency.

Essential Technical Properties and Trade Terminology for automatic dog feeders for outside

What Are the Key Technical Properties of Automatic Dog Feeders for Outdoor Use?

When evaluating automatic dog feeders for outdoor applications, several critical technical properties are essential to ensure durability, functionality, and safety. Understanding these specifications can help B2B buyers make informed purchasing decisions.

-

Material Grade

Outdoor feeders should be constructed from high-grade, weather-resistant materials such as stainless steel or UV-resistant plastics. These materials not only ensure longevity against the elements but also prevent rust and corrosion, which are common concerns in outdoor settings. Selecting feeders made from durable materials is crucial for minimizing maintenance costs and enhancing the product’s lifespan. -

Capacity and Size Specifications

The capacity of the feeder, often measured in gallons or pounds of food, is vital for determining how often it needs to be refilled. For instance, a feeder that holds 25 pounds of kibble is ideal for larger dogs or multiple pets. Buyers should also consider the feeder’s dimensions to ensure it fits appropriately in the intended outdoor space while being accessible for pets. -

Power Requirements

Automatic feeders can be powered via different sources, including AC power, batteries, or solar energy. Understanding the power requirements (voltage and amperage) is crucial, especially in regions where electrical supply may be inconsistent. Buyers should evaluate whether the feeder can accommodate a solar panel or if it requires a direct power source, which can influence installation logistics. -

Timer and Programming Features

Many automatic feeders come equipped with programmable timers that allow for multiple feeding times throughout the day. The ability to set portions and schedules accurately is essential for maintaining a pet’s health. Buyers should look for models that offer user-friendly programming options, as complex setups can lead to operational errors. -

Weather Resistance and Protection Features

Since these feeders are designed for outdoor use, they should have features such as weatherproofing, secure lids, and possibly animal-proof designs to prevent access by wildlife. Understanding the level of protection against rain, snow, and pests is critical for ensuring the feeder functions correctly and remains hygienic. -

Portion Accuracy

The ability to dispense accurate food portions is crucial for pet health. Many feeders provide specifications on portion size accuracy, often measured in ounces. Buyers should ensure the feeder can handle different kibble sizes and shapes effectively, as this can impact feeding consistency.

What Are Common Trade Terms in the Outdoor Dog Feeder Industry?

Familiarity with industry jargon is crucial for B2B buyers, as it aids in effective communication and negotiation.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are then sold under another company’s brand. Understanding OEM relationships can help buyers identify quality suppliers and negotiate better terms. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for small businesses or startups. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products. It helps buyers compare costs and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing shipping, insurance, and delivery obligations, particularly when sourcing products globally. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This is a crucial factor for inventory planning and can impact a company’s ability to meet customer demand. -

Warranty and Service Agreements

These terms define the manufacturer’s commitment to repair or replace defective products. Understanding warranty details helps buyers assess long-term costs and risks associated with the products.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their procurement strategies for outdoor automatic dog feeders, ensuring they select the best products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the automatic dog feeders for outside Sector

What are the Current Market Dynamics and Key Trends in Automatic Dog Feeders for Outside?

The automatic dog feeder market for outdoor use is witnessing significant growth driven by increasing pet ownership and a shift towards convenience in pet care. Globally, the demand for automated pet care solutions is rising, particularly in regions such as Africa, South America, the Middle East, and Europe. Key trends include the integration of smart technology in feeders, allowing pet owners to manage feeding schedules remotely via mobile applications. This tech-driven shift is particularly appealing in urban areas where busy lifestyles demand efficient pet care solutions.

Additionally, the rise in e-commerce is reshaping how B2B buyers source products. Buyers now prefer online platforms that offer comprehensive product details, customer reviews, and competitive pricing. Suppliers must adapt to this trend by enhancing their digital presence and offering streamlined purchasing processes. Furthermore, sustainability is becoming a vital consideration, with buyers increasingly seeking products made from eco-friendly materials. This aligns with the global emphasis on reducing environmental impact, prompting manufacturers to innovate in materials and production processes.

Emerging markets in Africa and South America show potential for growth as disposable incomes rise and urbanization increases. This creates a unique opportunity for suppliers to tailor products to local preferences, such as designing feeders that withstand extreme weather conditions or cater to specific dog breeds prevalent in these regions.

How Important is Sustainability and Ethical Sourcing in the Automatic Dog Feeder Market?

Sustainability and ethical sourcing are gaining traction in the automatic dog feeder industry, with consumers and B2B buyers alike prioritizing products that minimize environmental impact. The production of outdoor feeders often involves materials that can harm the environment if not sourced responsibly. Therefore, suppliers that utilize recycled materials or sustainable manufacturing processes can distinguish themselves in a crowded market. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) can enhance credibility and appeal to eco-conscious buyers.

Moreover, the environmental impact of packaging is a crucial aspect of the supply chain. Buyers are increasingly looking for suppliers that offer minimalistic, recyclable, or biodegradable packaging solutions. This not only reduces waste but also aligns with the growing consumer preference for brands that demonstrate environmental responsibility.

Illustrative image related to automatic dog feeders for outside

Ethical sourcing practices, including fair labor conditions and transparency in the supply chain, are also critical. B2B buyers are more inclined to partner with suppliers that can guarantee ethical practices, as this reflects positively on their brand and meets the expectations of their customers.

How Has the Automatic Dog Feeder Market Evolved Over Time?

The evolution of automatic dog feeders can be traced back to the early 20th century when the first basic gravity feeders were introduced. These simple devices allowed pet owners to provide food without the need for constant manual refilling. Over the decades, advancements in technology led to the introduction of electric and battery-operated feeders, which offered more precise portion control and scheduling capabilities.

In recent years, the market has shifted dramatically with the advent of smart technology. Modern feeders now incorporate Wi-Fi connectivity, enabling remote feeding control and monitoring through mobile apps. This evolution has not only enhanced user convenience but also catered to the growing trend of pet owners seeking more integrated and automated solutions for pet care. As the market continues to evolve, the focus on sustainability and ethical sourcing will likely shape the future of product development and sourcing strategies within the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic dog feeders for outside

-

How do I solve issues with outdoor automatic dog feeders not working properly?

To troubleshoot outdoor automatic dog feeders, first ensure that the feeder is correctly powered, as some models require specific voltage levels (e.g., 110-120V or 220-240V). Inspect the digital timer settings to confirm that feeding times are programmed correctly. Regularly check for clogs in the dispensing chute caused by moisture or food residue, and ensure the feeder is mounted securely to avoid damage from wind or animals. If problems persist, refer to the manufacturer’s customer support for specific guidance or replacement parts. -

What is the best type of automatic dog feeder for outdoor use?

The best outdoor automatic dog feeders are those with weather-resistant features and sufficient capacity for your pet’s needs. Look for models with programmable digital timers that allow multiple feeding times throughout the day. Additionally, feeders with adjustable portion sizes are ideal for various dog breeds. Consider feeders designed to deter pests, such as raccoons, by incorporating protective covers or mounting options. Researching customer reviews and testing different models can help determine the most suitable option for your requirements. -

How can I ensure the quality of automatic dog feeders from international suppliers?

To ensure quality, conduct thorough research on potential suppliers, focusing on their manufacturing processes and certifications. Request samples to evaluate the feeders’ materials, functionality, and durability. Establish clear quality assurance (QA) criteria and communicate these expectations to suppliers before placing larger orders. Additionally, consider suppliers with positive feedback from other international buyers and those who offer warranties or return policies on their products. -

What are the typical minimum order quantities (MOQs) for automatic dog feeders?

Minimum order quantities for automatic dog feeders can vary significantly based on the supplier and the product’s specifications. Many manufacturers might have MOQs ranging from 50 to 100 units, while others may offer flexibility for smaller orders, particularly for first-time buyers. It’s advisable to negotiate MOQs based on your purchasing capacity, and inquire if the supplier can accommodate smaller trial orders to gauge product performance before committing to larger quantities. -

What payment terms are common when purchasing automatic dog feeders internationally?

Common payment terms for international purchases may include options like advance payment, letters of credit, or payment upon delivery. Many suppliers prefer a deposit (usually 30-50%) upfront, with the balance due before shipping or upon receipt of goods. Always verify the payment methods accepted by the supplier, and consider using secure platforms that offer buyer protection. Discussing payment terms upfront can help avoid misunderstandings and ensure a smooth transaction. -

How do I handle logistics when importing outdoor dog feeders?

Logistics for importing outdoor dog feeders involve several steps, including selecting a reliable freight forwarder experienced in handling pet products. Ensure proper documentation, such as invoices, packing lists, and import permits, is prepared to comply with customs regulations in your destination country. Discuss shipping options with your supplier, considering factors like shipping time, costs, and insurance coverage. Staying informed about local import duties and taxes will help you budget effectively for the overall cost. -

What customization options are available for automatic dog feeders?

Many suppliers offer customization options for automatic dog feeders, including size, color, branding, and features such as programmable timers or integrated cameras. When discussing customization, outline your specific requirements, and ask for any additional costs associated with these modifications. It’s beneficial to review past projects or customer examples to understand the supplier’s capabilities and ensure that your specifications can be met effectively. -

How can I assess supplier reliability in the automatic dog feeder market?

Assessing supplier reliability involves reviewing their business history, client testimonials, and industry certifications. Request references from previous clients to gauge their experience and satisfaction with the supplier’s products and services. Additionally, evaluate the supplier’s communication responsiveness and willingness to address concerns or provide solutions. Attending trade shows or industry events can also help establish direct relationships with potential suppliers, further enhancing trust and reliability in your sourcing decisions.

Top 3 Automatic Dog Feeders For Outside Manufacturers & Suppliers List

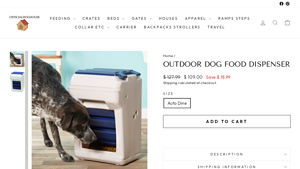

1. Official Dog House – Outdoor Automatic Dog Food Dispenser

Domain: officialdoghouse.com

Registered: 2005 (20 years)

Introduction: {“product_name”: “Outdoor Automatic Dog Food Dispenser”, “regular_price”: “$127.99”, “sale_price”: “$109.00”, “savings”: “$18.99”, “capacity”: “25 lbs”, “material”: “high density plastic”, “dimensions”: “22.75’H x 14.25’W x 14.88’D”, “features”: [“easy loading”, “pest resistant”, “gravity feed”, “mountable to wall or fence”, “will not rust”], “shipping_cost”: “$6.99”, “shipping_time”: “2-4 busines…

2. Outdoor Dog Feeder – Timer-Enabled Metal Dispenser

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Outdoor dog feeder with timer functionality (app or manual), not gravity-fed, dispenses set amount at set times, made of metal or stainless steel (chew-proof), durable against puppy attempts to access food, battery-operated or corded with battery backup, can be secured to the wall, price ideally under $100.

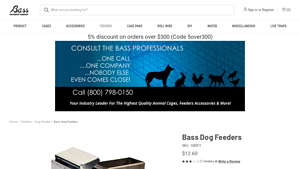

3. Bass Equipment – Bass Dog Feeders

Domain: bassequipment.com

Registered: 1998 (27 years)

Introduction: Bass Dog Feeders SKU: GBDF2 Price: $12.60 Size Options: 6½”H x 6½”D x 5½”W galvanized, 6½”H x 6½”D x 5½”W galvanized with cover, 6½”H x 6½”D x 5½”W stainless steel, 10″H x 6½”D x 5½”W galvanized, 10″H x 6½”D x 5½”W galvanized with cover, 10″H x 6½”D x 5½”W stainless steel, 12 ½” x 8”D x 8 1/4”W stainless steel Features: Practically indestructible, easy to use, wider mouth for easier access, sloped…

Strategic Sourcing Conclusion and Outlook for automatic dog feeders for outside

As the demand for outdoor automatic dog feeders continues to grow, strategic sourcing becomes essential for international B2B buyers aiming to capitalize on this lucrative market. Key considerations include selecting products that offer durability, weather resistance, and adjustable feeding capabilities to cater to various dog sizes and dietary needs. Understanding local market preferences and sourcing from reliable manufacturers can ensure a competitive edge.

Illustrative image related to automatic dog feeders for outside

Investing in high-quality feeders not only enhances customer satisfaction but also builds brand loyalty, particularly in regions like Africa, South America, the Middle East, and Europe, where pet ownership is on the rise. Additionally, leveraging advanced technology—such as programmable timers and smart home integration—can differentiate your offerings in a crowded marketplace.

Looking ahead, it is crucial for B2B buyers to stay informed about emerging trends and innovations in the pet care industry. By proactively engaging with suppliers and exploring diverse product ranges, businesses can position themselves for success. Embrace the opportunity to enhance your product portfolio and meet the evolving needs of pet owners globally.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to automatic dog feeders for outside

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.