Introduction: Navigating the Global Market for automatic rabbit feeder

In the ever-evolving landscape of animal husbandry, sourcing an automatic rabbit feeder can pose a significant challenge for B2B buyers seeking efficiency and reliability. As the demand for sustainable and humane rabbit farming practices grows, the need for innovative feeding solutions has never been more critical. This guide provides an extensive overview of the automatic rabbit feeder market, addressing various types of feeders, their applications, and the factors influencing purchasing decisions, including supplier vetting and cost considerations.

International buyers from regions such as Africa, South America, the Middle East, and Europe will find this resource invaluable in navigating the complexities of global sourcing. By delving into the nuances of different feeder designs, materials, and technologies, this guide equips businesses with the knowledge to make informed investments that enhance productivity and animal welfare. Furthermore, it emphasizes the importance of selecting suppliers who adhere to quality standards, ensuring that your investment yields long-term benefits.

With this comprehensive guide, B2B buyers will gain insights into optimizing their purchasing strategies, mitigating risks, and ultimately elevating their rabbit farming operations. The journey towards efficient feeding solutions begins here, empowering businesses to thrive in a competitive market while meeting the needs of both their animals and customers.

Table Of Contents

- Top 4 Automatic Rabbit Feeder Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automatic rabbit feeder

- Understanding automatic rabbit feeder Types and Variations

- Key Industrial Applications of automatic rabbit feeder

- 3 Common User Pain Points for ‘automatic rabbit feeder’ & Their Solutions

- Strategic Material Selection Guide for automatic rabbit feeder

- In-depth Look: Manufacturing Processes and Quality Assurance for automatic rabbit feeder

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic rabbit feeder’

- Comprehensive Cost and Pricing Analysis for automatic rabbit feeder Sourcing

- Alternatives Analysis: Comparing automatic rabbit feeder With Other Solutions

- Essential Technical Properties and Trade Terminology for automatic rabbit feeder

- Navigating Market Dynamics and Sourcing Trends in the automatic rabbit feeder Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automatic rabbit feeder

- Strategic Sourcing Conclusion and Outlook for automatic rabbit feeder

- Important Disclaimer & Terms of Use

Understanding automatic rabbit feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gravity Feeders | Simple design, uses gravity to dispense food | Small to medium-scale rabbit farms | Pros: Low maintenance, easy to use. Cons: Limited control over feeding quantity. |

| Electronic Timed Feeders | Programmable feeding schedules, automated dispensing | Large-scale commercial rabbit operations | Pros: Precision feeding, reduces labor. Cons: Higher initial investment. |

| Creep Feeders | Designed for young rabbits, prevents larger ones from accessing food | Breeding and nursery setups | Pros: Promotes healthy growth of young rabbits. Cons: May require additional space. |

| Combo Feeders | Combines hay and pellets in one unit | Versatile use in various rabbit farming setups | Pros: Reduces equipment needs, encourages varied diet. Cons: Can be more expensive. |

| DIY Feeders | Custom-built, often from repurposed materials | Small farms or personal use | Pros: Cost-effective, customizable. Cons: May lack durability and efficiency. |

What are Gravity Feeders and Their B2B Applications?

Gravity feeders are a fundamental type of automatic rabbit feeder that utilizes gravity to dispense food. These feeders are straightforward in design, making them easy to use and maintain. They are particularly suitable for small to medium-scale rabbit farms where simplicity and low-cost solutions are essential. B2B buyers should consider the ease of refilling and the potential for overfeeding, as these feeders do not allow for precise control over food quantities.

How Do Electronic Timed Feeders Enhance Feeding Efficiency?

Electronic timed feeders offer advanced features, allowing users to program specific feeding schedules and quantities. This technology is ideal for large-scale commercial rabbit operations, where consistent feeding is crucial for productivity and animal health. Buyers should weigh the initial investment against long-term labor savings and the precision of feeding, as these feeders can significantly reduce the time spent on routine tasks.

Why Choose Creep Feeders for Young Rabbits?

Creep feeders are specifically designed to cater to young rabbits while preventing access to larger rabbits. This type of feeder is essential in breeding and nursery setups, as it ensures that young rabbits receive adequate nutrition without competition. When purchasing, B2B buyers should consider the space requirements and the feeder’s ability to accommodate growing rabbits, as these feeders can promote healthy growth and development.

What Are the Benefits of Combo Feeders in Rabbit Farming?

Combo feeders combine hay and pellets, providing a versatile feeding solution for various rabbit farming setups. They are particularly useful in environments where a varied diet is encouraged, helping to maintain optimal health among rabbits. Buyers should evaluate the cost-effectiveness of combo feeders against the need for separate feeding solutions, as these units can simplify feeding routines and reduce equipment needs.

How Can DIY Feeders Be a Practical Solution for Small Farms?

DIY feeders are often constructed from repurposed materials, making them a cost-effective option for small farms or personal use. While these feeders allow for customization to meet specific needs, they may lack the durability and efficiency of commercially available options. B2B buyers should assess their own capacity for maintenance and the longevity of DIY solutions, weighing the benefits of cost savings against potential drawbacks in performance.

Key Industrial Applications of automatic rabbit feeder

| Industry/Sector | Specific Application of automatic rabbit feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Large-scale rabbit farming for meat production | Increases feeding efficiency and reduces labor costs | Durability, ease of cleaning, and feed type compatibility |

| Research Institutions | Breeding and research on rabbit genetics | Ensures consistent feeding schedules for experimental accuracy | Customization options and data tracking capabilities |

| Pet Supply Retail | Retailing automatic feeders for pet owners | Expands product offerings and meets customer demand | Quality assurance and supplier reliability |

| Animal Welfare Groups | Rescue and rehabilitation centers for rabbits | Facilitates proper care and feeding during rehabilitation | Cost-effectiveness and humane design |

| Educational Institutions | Teaching animal husbandry practices | Provides hands-on learning tools for students | Safety standards and ease of use |

How is Automatic Rabbit Feeder Utilized in Large-scale Rabbit Farming?

In large-scale rabbit farming, automatic feeders are essential for efficiently managing feeding schedules across numerous animals. These feeders help mitigate labor costs by automating the feeding process, allowing farmers to focus on other critical areas of production. Buyers in this sector should prioritize feeders that are durable, easy to clean, and compatible with various types of feed to ensure long-term usability and operational efficiency.

What Role Does Automatic Rabbit Feeder Play in Research Institutions?

Research institutions that focus on animal genetics and breeding utilize automatic rabbit feeders to maintain consistent feeding schedules, which is crucial for experimental accuracy. These feeders help ensure that all rabbits receive the same nutrition, thereby reducing variables in research outcomes. Buyers should consider customization options that allow for precise control over feeding amounts and schedules, as well as data tracking capabilities to monitor feeding patterns.

Illustrative image related to automatic rabbit feeder

How Can Pet Supply Retailers Benefit from Automatic Rabbit Feeders?

Pet supply retailers can enhance their product offerings by including automatic rabbit feeders in their inventory. These feeders cater to the growing demand among pet owners who seek convenience and efficiency in caring for their pets. When sourcing these feeders, retailers must ensure quality assurance and supplier reliability to build customer trust and satisfaction.

In What Ways Do Animal Welfare Groups Use Automatic Rabbit Feeders?

Animal welfare groups that operate rescue and rehabilitation centers for rabbits utilize automatic feeders to facilitate proper care during the rehabilitation process. These feeders allow for consistent and reliable feeding, which is essential for the health and recovery of rescued rabbits. Cost-effectiveness and humane design are critical factors for buyers in this sector, as they aim to provide the best care while managing limited budgets.

How Do Educational Institutions Incorporate Automatic Rabbit Feeders in Teaching?

Educational institutions that offer programs in animal husbandry use automatic rabbit feeders as practical teaching tools. These feeders provide students with hands-on experience in managing animal care, preparing them for future careers in agriculture or veterinary sciences. Buyers should focus on sourcing feeders that meet safety standards and are easy to use, ensuring that students can learn effectively without compromising animal welfare.

3 Common User Pain Points for ‘automatic rabbit feeder’ & Their Solutions

Scenario 1: Ensuring Consistent Feeding for Breeding Operations

The Problem: B2B buyers managing large-scale rabbit breeding operations often struggle with maintaining consistent feeding schedules. With hundreds of rabbits to care for, it’s challenging to ensure each animal receives the appropriate amount of food at the right times, especially during busy periods or staff shortages. Inconsistent feeding can lead to health issues, weight fluctuations, and ultimately affect the breeding cycles of rabbits, leading to financial losses.

Illustrative image related to automatic rabbit feeder

The Solution: Investing in high-quality automatic rabbit feeders can mitigate this problem significantly. Buyers should look for feeders that allow for programmable feeding schedules, ensuring that each rabbit receives the right quantity of food at designated times. It’s essential to choose feeders with adjustable settings to accommodate the varying dietary needs of different breeds or age groups. Buyers should also prioritize feeders made from durable, chew-resistant materials to withstand the rigors of frequent use. Additionally, implementing a monitoring system, such as a digital app that tracks feed consumption, can help in adjusting the feeding schedules in real-time, ensuring optimal health and productivity.

Scenario 2: Managing Feed Costs and Reducing Waste

The Problem: Cost control is a significant concern for businesses involved in rabbit farming. Overfeeding or inefficient feeding systems can lead to excessive waste and higher operational costs. Many B2B buyers find themselves facing financial strain due to poor feed management, as traditional feeding methods often do not optimize the amount of food provided, leading to both waste and increased feed expenses.

The Solution: Automatic rabbit feeders designed with feed-saving features can be a game-changer for managing costs. Buyers should seek feeders that minimize spillage and allow for precise portion control. Opting for models with built-in sensors can help in detecting when rabbits have eaten, reducing the likelihood of overfeeding. Additionally, sourcing feeders that can handle bulk feed can lower costs by reducing the frequency of purchases. It’s also beneficial to establish a feeding plan that incorporates the use of high-quality feed that meets nutritional standards without the need for excessive quantities. Regularly reviewing feeding practices and adjusting them based on actual consumption data can further enhance cost-effectiveness.

Scenario 3: Addressing Hygiene and Disease Prevention

The Problem: In rabbit farming, maintaining hygiene is crucial to preventing disease outbreaks. B2B buyers often face challenges with traditional feeders, as they can become contaminated with waste or leftover food, leading to health risks for the rabbits. Poor hygiene practices can result in costly veterinary bills and losses due to sick animals, affecting the overall profitability of the business.

The Solution: Automatic rabbit feeders that are easy to clean and designed with hygiene in mind can significantly alleviate this issue. Buyers should select feeders with smooth surfaces and minimal crevices where waste can accumulate, facilitating easier cleaning. Models that can be disassembled for thorough sanitation are ideal. Additionally, incorporating self-cleaning features or materials with antimicrobial properties can help in maintaining a hygienic feeding environment. It’s also wise to develop a regular cleaning schedule to ensure that all feeding equipment is sanitized, which will ultimately enhance the health of the rabbits and reduce the risk of disease. Investing in hygiene-focused feeders not only protects the animals but also boosts the business’s reputation and bottom line.

Illustrative image related to automatic rabbit feeder

Strategic Material Selection Guide for automatic rabbit feeder

When selecting materials for automatic rabbit feeders, it is essential to consider factors such as durability, cost, and suitability for the specific needs of rabbits. The following analysis examines four common materials used in the manufacturing of these feeders, highlighting their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Plastic in Automatic Rabbit Feeders?

Plastic, particularly high-density polyethylene (HDPE) and polypropylene (PP), is widely used in automatic rabbit feeders. These materials are lightweight, resistant to moisture, and easy to mold into various shapes. They also exhibit good chemical resistance, making them suitable for handling different types of rabbit feed.

Pros and Cons: Plastics are generally more affordable than metals and can be produced in various colors and designs. However, they may not withstand extreme temperatures or heavy impacts as well as metals, leading to potential durability issues in harsh environments.

Impact on Application: Plastic feeders are typically compatible with dry feed but may not be suitable for wet or high-moisture feeds, which could lead to degradation over time.

International Considerations: Buyers should ensure that the plastics used are food-grade and comply with local regulations regarding food safety. For regions like Africa and South America, it’s crucial to check for compliance with local standards, which may differ from ASTM or DIN standards commonly referenced in Europe.

How Does Metal Compare in Terms of Durability for Automatic Rabbit Feeders?

Metal materials, such as galvanized steel or stainless steel, are known for their durability and strength. These materials can withstand high temperatures and are resistant to corrosion, making them ideal for outdoor use.

Pros and Cons: Metal feeders are robust and can endure the wear and tear of daily use. However, they tend to be heavier and more expensive than plastic options. Manufacturing complexity is also higher, often requiring specialized equipment for shaping and welding.

Impact on Application: Metal feeders can handle a variety of feed types, including moist feeds, without the risk of degradation. However, they may require regular maintenance to prevent rusting, especially in humid environments.

International Considerations: Buyers should be aware of the specific grades of stainless steel used, as lower grades may not perform well in humid or corrosive environments. Compliance with international standards for food safety and material quality is also essential.

What Role Does Wood Play in Automatic Rabbit Feeders?

Wood, particularly untreated hardwood, is sometimes used in rabbit feeders for its natural aesthetic and insulation properties. It is biodegradable and can be sourced sustainably.

Pros and Cons: Wooden feeders can be visually appealing and provide good insulation. However, they are susceptible to moisture, which can lead to mold growth and decay over time. Additionally, they may require more maintenance compared to plastic or metal feeders.

Impact on Application: Wooden feeders are best suited for dry feed and should be treated with non-toxic finishes to ensure safety. They may not be ideal for regions with high humidity or frequent rainfall.

International Considerations: Buyers should ensure that the wood used is sourced sustainably and complies with local regulations regarding chemical treatments. In regions like the Middle East, where humidity can be high, it’s crucial to consider the longevity of wooden materials.

How Do Composite Materials Enhance Automatic Rabbit Feeders?

Composite materials, which combine plastics with other materials (like wood fibers), offer a unique blend of properties. They are designed to mimic the appearance of wood while providing the durability of plastic.

Pros and Cons: Composites are resistant to moisture and pests, making them suitable for outdoor use. However, they can be more expensive than traditional plastics and may require specific manufacturing processes.

Impact on Application: Composite feeders can handle various feed types and are less prone to degradation than pure wood. They provide a good balance of aesthetics and functionality.

International Considerations: Buyers should verify that composite materials meet local safety standards and are suitable for the intended environment, especially in regions with diverse climates.

Summary Table

| Material | Typical Use Case for automatic rabbit feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Dry feed dispensers | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Metal | Outdoor feeders for various feed types | High durability and corrosion resistance | Heavier and more expensive | High |

| Wood | Aesthetic feeders for dry feed | Natural look and insulation properties | Susceptible to moisture and decay | Medium |

| Composite | Versatile feeders for varied environments | Moisture resistant and durable | Higher manufacturing complexity | Medium to High |

This strategic material selection guide aims to assist B2B buyers in making informed decisions when sourcing automatic rabbit feeders, ensuring that the chosen materials align with their operational needs and regional standards.

Illustrative image related to automatic rabbit feeder

In-depth Look: Manufacturing Processes and Quality Assurance for automatic rabbit feeder

What Are the Key Stages in the Manufacturing Process of Automatic Rabbit Feeders?

Manufacturing automatic rabbit feeders involves several critical stages, each designed to ensure efficiency, durability, and functionality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing process begins with the selection of high-quality raw materials. Common materials for automatic rabbit feeders include food-grade plastics, stainless steel, and galvanized metal. These materials are chosen for their durability, ease of cleaning, and resistance to corrosion. Suppliers often conduct material tests to ensure compliance with safety and quality standards.

-

Forming: After materials are prepared, they undergo forming processes. This may involve injection molding for plastic components, which allows for precise shapes and sizes. For metal parts, techniques such as stamping or laser cutting may be used. These processes are crucial for creating the feeder’s structure, ensuring that it can withstand the rigors of daily use while maintaining an attractive design.

-

Assembly: Once the individual components are formed, they are assembled. This stage can be manual or automated, depending on the scale of production. Automated assembly lines enhance efficiency and reduce human error, while skilled workers ensure that parts fit together correctly. Assembly also includes the integration of electronic components, such as sensors and timers, which are essential for automatic feeding mechanisms.

-

Finishing: The final stage involves finishing processes that enhance the product’s aesthetics and functionality. This may include painting, powder coating, or applying protective coatings to prevent rust and wear. Quality checks are performed during this stage to ensure that the finish meets industry standards and does not adversely affect the feeder’s performance.

How Is Quality Assurance Implemented in Automatic Rabbit Feeder Manufacturing?

Quality assurance (QA) is essential to maintaining high standards in the manufacturing of automatic rabbit feeders. It involves several international standards, industry-specific certifications, and quality checkpoints throughout the production process.

-

International Standards: Compliance with international standards such as ISO 9001 is critical for manufacturers. This standard outlines criteria for a quality management system, ensuring that products consistently meet customer and regulatory requirements. Manufacturers may also seek CE marking, which indicates conformity with health, safety, and environmental protection standards within the European Economic Area.

-

Industry-Specific Certifications: In addition to general quality standards, suppliers may pursue certifications relevant to the animal husbandry industry, such as the American Pet Products Association (APPA) standards. These certifications help ensure that products are safe for animal use and meet specific performance criteria.

-

Quality Control Checkpoints: Quality control (QC) is integrated at various points in the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify their quality and compliance with specifications.

– In-Process Quality Control (IPQC): During production, operators conduct checks to monitor the quality of the assembly and forming processes. This can include measuring dimensions and testing the functionality of components.

– Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive inspection is conducted to ensure that the finished feeders meet all quality standards and function as intended. -

Common Testing Methods: Various testing methods are employed to assess product quality. These may include:

– Mechanical Testing: Assessing the structural integrity and durability of materials.

– Electrical Testing: Ensuring that any electronic components function correctly and safely.

– Safety Testing: Verifying that the feeders do not pose any hazards to rabbits or their environment.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial.

-

Supplier Audits: Conducting audits of potential suppliers allows buyers to assess their manufacturing processes and quality control measures firsthand. This can include reviewing documentation, visiting production facilities, and interviewing quality assurance personnel.

-

Quality Reports: Requesting quality control reports from suppliers provides insight into their QA processes and the outcomes of previous inspections. These reports should include data on defect rates, compliance with standards, and corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services can perform random inspections, product testing, and audits to ensure compliance with international standards.

-

Certification Verification: Buyers should verify any certifications claimed by suppliers. This can often be done through the certifying body, ensuring that the supplier maintains their certification status and adheres to relevant standards.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating quality control and certification nuances is essential for B2B buyers sourcing automatic rabbit feeders from international suppliers.

Illustrative image related to automatic rabbit feeder

-

Regional Standards: Different regions may have varying standards and regulations regarding animal husbandry products. Understanding these differences is crucial for compliance and market acceptance. For instance, products sold in the European market may require CE marking, while those in the US may need to comply with APPA standards.

-

Language and Communication: Language barriers can pose challenges in understanding quality documentation and certifications. Buyers should ensure that they have access to clear and accurate translations of all relevant materials.

-

Cultural Differences: Business practices and attitudes toward quality assurance can vary significantly between cultures. B2B buyers should be aware of these differences when negotiating contracts and establishing quality expectations with suppliers.

-

Supply Chain Transparency: Maintaining transparency throughout the supply chain is vital. Buyers should seek suppliers who are willing to share information about their sourcing, production processes, and quality control measures, fostering trust and accountability.

By understanding the manufacturing processes and quality assurance measures associated with automatic rabbit feeders, B2B buyers can make informed decisions, ensuring that they source products that meet their quality standards and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic rabbit feeder’

Introduction

When sourcing automatic rabbit feeders, international B2B buyers must navigate a variety of factors to ensure they select the most suitable products for their operations. This guide provides a clear, actionable checklist to facilitate the procurement process, focusing on essential steps to identify reliable suppliers and quality products.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, outline the specific technical requirements for the automatic rabbit feeders you need. Consider factors such as capacity, materials, feeding mechanisms, and whether you require programmable features. Clearly defined specifications will help you communicate your needs effectively and streamline the selection process.

- Capacity Needs: Determine how many rabbits will be fed and the volume of feed needed to avoid frequent refilling.

- Material Considerations: Opt for durable, chew-resistant materials suitable for outdoor use, especially in varying climates.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in automatic rabbit feeders. Look for companies with a solid reputation in the market and experience in exporting to your region. Use industry directories, trade shows, and online platforms to compile a list of potential suppliers.

Illustrative image related to automatic rabbit feeder

- Industry Experience: Prioritize suppliers with a proven track record in the animal husbandry sector.

- Geographical Reach: Ensure they have experience shipping to your target regions, such as Africa, South America, or Europe.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that potential suppliers hold relevant certifications that demonstrate compliance with industry standards. This includes quality management systems, safety certifications, and environmental compliance.

- ISO Certifications: Look for ISO 9001 certification, which indicates a commitment to quality management.

- Local Regulations: Ensure compliance with any local agricultural and animal welfare regulations applicable in your market.

Step 4: Request Samples and Product Specifications

Once you’ve narrowed down your supplier options, request samples of the automatic rabbit feeders. Evaluating physical products allows you to assess quality, design, and functionality firsthand.

- Quality Assessment: Check for durability and ease of use to ensure they meet your operational needs.

- User Experience: Consider how easy it is for rabbits to access the feed and how well the feeder functions in your environment.

Step 5: Compare Pricing and Terms

Analyze pricing structures among suppliers, considering not only the base price but also shipping costs, payment terms, and bulk order discounts. This will help you gauge the overall value of the offerings.

- Cost vs. Quality: Ensure that lower prices do not compromise quality; prioritize suppliers who provide a balance of affordability and reliability.

- Negotiation Opportunities: Explore potential for negotiating better terms, especially for larger orders or long-term partnerships.

Step 6: Check References and Reviews

Before finalizing your decision, seek references from other buyers who have procured similar products from the suppliers you are considering. Reviews can provide insights into supplier reliability and product performance.

- Buyer Feedback: Look for testimonials that highlight customer service, product quality, and after-sales support.

- Problem Resolution: Inquire about how suppliers handle issues or defects to ensure they provide adequate support.

Step 7: Finalize Your Purchase Agreement

Once you’ve selected a supplier, draft a detailed purchase agreement that outlines product specifications, pricing, delivery timelines, and payment terms. This protects both parties and ensures clarity throughout the transaction.

- Clear Terms: Include clauses for warranty, returns, and support to safeguard your investment.

- Follow-Up: Establish a timeline for follow-up communication to address any concerns during the delivery process.

By following this checklist, B2B buyers can confidently navigate the sourcing process for automatic rabbit feeders, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for automatic rabbit feeder Sourcing

What Are the Key Cost Components for Automatic Rabbit Feeders?

When sourcing automatic rabbit feeders, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials—such as plastic, metal, or a combination of both—significantly affects the price. High-quality, durable materials may lead to higher initial costs but can reduce long-term expenses through increased durability and reduced maintenance.

-

Labor: Labor costs vary depending on the manufacturing region. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the trade-off with quality.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: The initial setup for production, including molds and dies, can represent a significant upfront investment. Custom designs may require specialized tooling, increasing costs.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability and safety, particularly for food-related equipment. While it adds to costs, it can prevent expensive recalls and damage to brand reputation.

-

Logistics: Shipping and handling costs vary based on the destination. Factors such as distance, mode of transport, and customs duties should be considered, especially for international buyers.

-

Margin: Suppliers typically add a profit margin to cover their costs and generate revenue. Understanding typical margins in the industry can aid in negotiations.

How Do Price Influencers Affect Automatic Rabbit Feeder Sourcing?

Several factors can influence the pricing of automatic rabbit feeders:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Buyers should assess their needs against supplier MOQs to optimize costs.

-

Specifications and Customization: Customized feeders tailored to specific requirements can incur additional charges. Buyers must weigh the benefits of customization against budget constraints.

-

Material Choices: The selection of materials not only affects the durability and functionality of the feeders but also significantly impacts the price. Sustainable or high-performance materials may command premium prices.

-

Quality and Certifications: Products that meet specific industry certifications may be more expensive but can assure compliance with health and safety standards, which is critical for B2B buyers in various markets.

-

Supplier Factors: Supplier reliability, reputation, and production capabilities can all influence pricing. Established suppliers may charge more due to perceived quality and service.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is vital. These terms dictate who bears the cost and risk during transport, impacting the total landed cost.

What Negotiation Strategies Can Help Buyers Achieve Cost-Efficiency?

For B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, effective negotiation is key to achieving cost-efficiency:

Illustrative image related to automatic rabbit feeder

-

Research and Benchmarking: Conduct thorough market research to understand average prices and supplier offerings. This knowledge empowers buyers during negotiations.

-

Long-term Partnerships: Establishing long-term relationships with suppliers can lead to better pricing structures, as suppliers are often willing to offer discounts for loyalty and consistent orders.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial purchase price. Consider factors such as maintenance, durability, and operational costs over the feeder’s lifespan.

-

Flexibility in Order Size: If feasible, negotiate flexibility in order sizes to balance between meeting MOQ requirements and obtaining the best possible pricing.

-

Cultural Considerations: Be aware of cultural differences in negotiation styles, especially when dealing with suppliers from different regions. Understanding these nuances can enhance communication and foster better deals.

Are There Pricing Nuances for International Buyers to Consider?

International buyers should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can impact the total cost. Locking in prices at a favorable exchange rate may be beneficial.

-

Tariffs and Import Duties: Import regulations can add unexpected costs. Familiarize yourself with these fees to avoid surprises.

-

Shipping Costs: Global shipping rates can vary significantly. Assess shipping options and negotiate terms to manage costs effectively.

-

Local Regulations: Compliance with local regulations regarding pet products can influence sourcing decisions. Ensure that suppliers are familiar with these regulations to avoid compliance issues.

Disclaimer

All prices and cost estimates mentioned are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing automatic rabbit feeder With Other Solutions

Exploring Alternatives to Automatic Rabbit Feeders for Effective Feeding Solutions

When considering the best feeding solutions for rabbits, it’s essential to evaluate various options, including automatic rabbit feeders and alternative methods. Each solution has unique features, advantages, and limitations that can significantly impact your operational efficiency and rabbit care. This analysis aims to help B2B buyers make informed decisions based on specific needs and circumstances.

| Comparison Aspect | Automatic Rabbit Feeder | Gravity Feeders | DIY Rabbit Feeders |

|---|---|---|---|

| Performance | High precision in feeding; can dispense food on a schedule. | Moderate; relies on gravity, which may lead to inconsistent feeding. | Varies; depends on design and materials used. |

| Cost | Generally higher initial investment, ranging from $50 to $200. | Low cost; typically between $10 and $50. | Minimal cost; often uses recycled materials. |

| Ease of Implementation | Requires setup and possible electrical connections. | Simple installation; just place it in the hutch. | Requires DIY skills and time for construction. |

| Maintenance | Low maintenance; occasional cleaning and battery replacement. | Low maintenance; infrequent refilling required. | Moderate; depends on materials used and need for repairs. |

| Best Use Case | Ideal for large operations needing precise feeding schedules. | Suitable for smaller setups or farms with fewer rabbits. | Best for casual rabbit owners looking for a low-cost solution. |

What Are the Advantages and Disadvantages of Gravity Feeders?

Gravity feeders are a popular alternative to automatic feeders. They work by relying on gravity to dispense food into a trough or container. The primary advantage is their low cost and simple implementation, making them accessible to small-scale rabbit farmers. However, the performance can vary, as the amount of food dispensed can be inconsistent, which may lead to overfeeding or underfeeding if not monitored closely. Additionally, they require regular manual refilling, which could be a drawback for those seeking a more automated solution.

How Do DIY Rabbit Feeders Compare?

DIY rabbit feeders offer a creative and cost-effective alternative for those who prefer to use available materials. These feeders can be made from items like plastic containers or recycled materials, allowing for customization based on specific needs. The primary advantage of DIY feeders is their minimal cost and the ability to tailor them to individual rabbits’ feeding habits. However, the performance can vary significantly based on the design and materials used, and they may require ongoing maintenance to ensure functionality. Additionally, building a DIY feeder demands some level of skill and time investment.

Conclusion: How Should B2B Buyers Choose the Right Feeding Solution?

When selecting a feeding solution for rabbits, B2B buyers should consider their operational scale, budget, and specific requirements. Automatic rabbit feeders are ideal for larger operations that demand precise control over feeding schedules and quantities, despite their higher cost. Gravity feeders provide a budget-friendly and straightforward option for smaller setups, while DIY feeders can cater to those looking for a customizable, low-cost solution. Ultimately, the best choice will depend on balancing performance needs with budget constraints and operational efficiency.

Illustrative image related to automatic rabbit feeder

Essential Technical Properties and Trade Terminology for automatic rabbit feeder

What Are the Key Technical Properties of an Automatic Rabbit Feeder?

Understanding the technical specifications of automatic rabbit feeders is crucial for B2B buyers to ensure product reliability, efficiency, and suitability for their operations. Here are the essential properties that need consideration:

1. Material Grade

The material used in automatic rabbit feeders typically includes high-density polyethylene (HDPE), stainless steel, or galvanized metal. HDPE is favored for its durability and resistance to moisture, while stainless steel offers superior strength and is rust-resistant. For B2B buyers, selecting the right material is vital as it affects the feeder’s lifespan, maintenance needs, and overall cost-effectiveness.

2. Capacity

Feeder capacity refers to the volume of feed the unit can hold, which is crucial for operational efficiency. Capacity is often measured in liters or kilograms. A larger capacity means less frequent refilling, which is particularly beneficial for businesses managing multiple rabbits. B2B buyers must evaluate their operational scale to choose a feeder with an appropriate capacity that aligns with their feeding schedules and rabbit population.

3. Feed Dispensing Mechanism

Automatic feeders can utilize various dispensing mechanisms, including gravity-fed systems, auger systems, or timer-controlled dispensers. Each mechanism has its pros and cons regarding feed accuracy and ease of use. Buyers should consider how these mechanisms align with their specific feeding protocols and the dietary needs of their rabbits to prevent overfeeding or underfeeding.

4. Adjustment Features

Many modern automatic feeders come with adjustable feed settings, allowing for tailored feeding amounts based on rabbit size and breed. This feature is significant for maintaining rabbit health and preventing obesity. B2B buyers should prioritize feeders that offer this flexibility to cater to different dietary requirements.

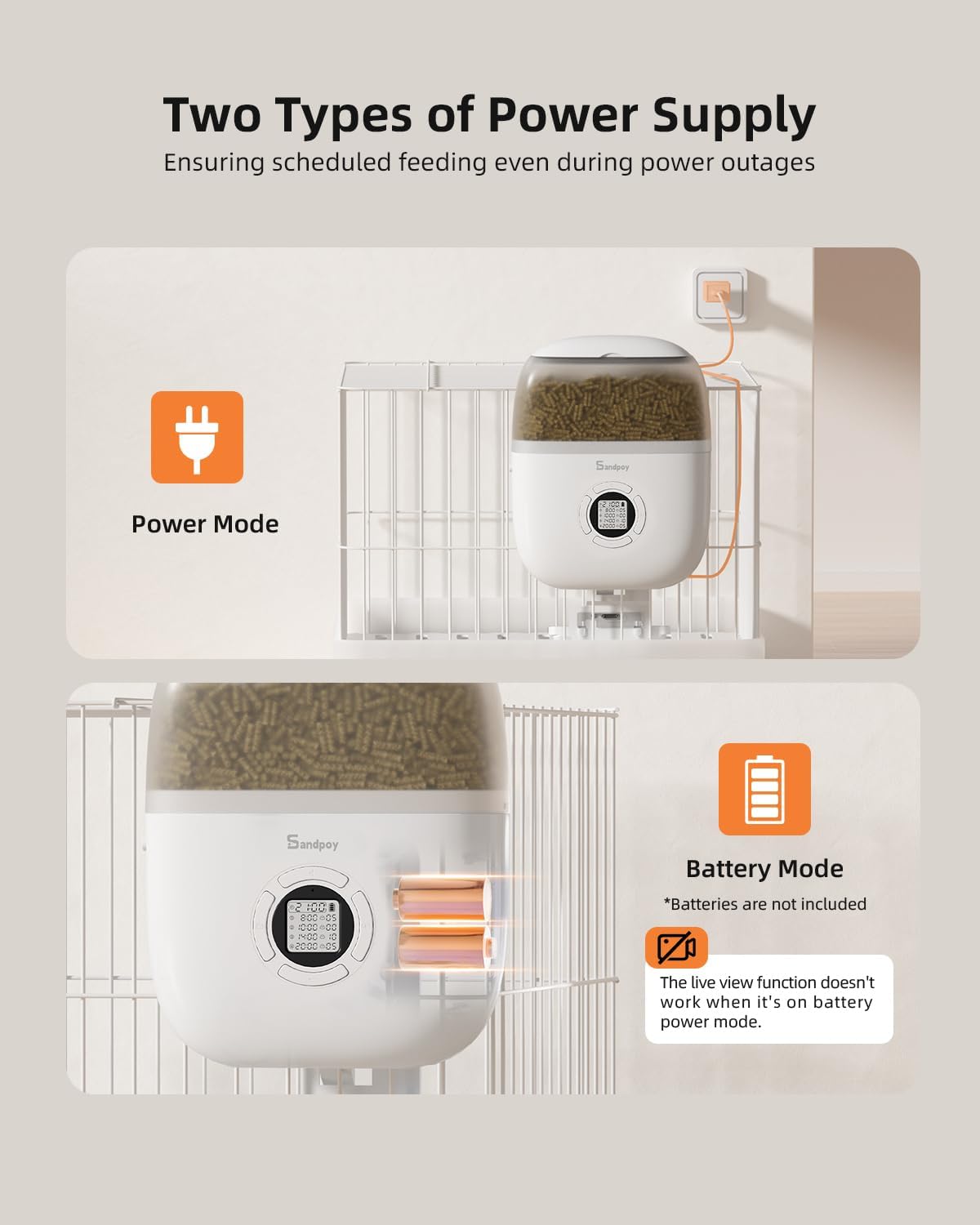

5. Power Source

Power sources for automatic feeders can be electric, solar-powered, or battery-operated. The choice of power source affects installation options, operational costs, and reliability. Buyers should assess their location’s power availability and their preference for sustainable energy solutions when selecting a feeder.

6. Maintenance and Cleanability

Maintenance requirements vary across feeder designs. Easy-to-clean models with removable parts reduce downtime and ensure hygiene, which is essential for animal health. B2B buyers should consider how often they can perform maintenance and choose feeders that facilitate quick cleaning processes.

What Are the Common Trade Terms Relevant to Automatic Rabbit Feeders?

Familiarity with industry terminology can enhance communication and streamline procurement processes. Here are several key trade terms relevant to automatic rabbit feeders:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding whether a feeder is produced by an OEM can indicate quality and reliability, as OEMs often adhere to strict manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units a supplier is willing to sell. This term is crucial for buyers in assessing initial investment costs and inventory management. Knowing the MOQ helps companies plan their purchases according to demand and budget constraints.

Illustrative image related to automatic rabbit feeder

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, using an RFQ can help ensure competitive pricing and better negotiations with suppliers, which is essential for maximizing profit margins.

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers involved in cross-border trade to avoid unexpected costs.

5. Warranty

A warranty is a guarantee from the manufacturer regarding the condition of the product and the terms for repair or replacement. For buyers, a robust warranty can indicate product quality and provide reassurance about their investment.

6. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. This term is important for buyers as it affects inventory planning and operational readiness. Understanding lead times helps businesses manage expectations and ensure timely availability of feeders.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operations and ensure the well-being of the rabbits in their care.

Navigating Market Dynamics and Sourcing Trends in the automatic rabbit feeder Sector

What Are the Key Trends Driving the Automatic Rabbit Feeder Market?

The automatic rabbit feeder market is experiencing a notable transformation driven by several global factors. First, increasing pet ownership, particularly in developing regions such as Africa and South America, is driving demand for convenient feeding solutions. This trend is amplified by a shift toward modernization in farming practices and the growing popularity of small-scale rabbit farming for meat and fiber production. Furthermore, advancements in technology are enabling the integration of smart features in feeders, such as IoT connectivity, which allows for remote monitoring and feeding schedules, appealing to tech-savvy consumers.

Emerging B2B sourcing trends reflect a focus on efficiency and cost-effectiveness. Buyers are increasingly looking for automated solutions that can reduce labor costs and improve feeding accuracy. This demand is further supported by the rise of online marketplaces, which facilitate easier access to a wider range of suppliers and products. International buyers, particularly from regions like the Middle East and Europe, are also exploring collaborations with local manufacturers to enhance supply chain resilience and ensure quicker delivery times.

Illustrative image related to automatic rabbit feeder

As the market evolves, sustainability is becoming a critical factor. Manufacturers are under pressure to adopt eco-friendly materials and practices, which not only appeal to environmentally conscious consumers but also align with regulatory requirements in various regions.

How Is Sustainability Influencing B2B Sourcing in the Automatic Rabbit Feeder Sector?

Sustainability and ethical sourcing are paramount in today’s B2B landscape, particularly in the automatic rabbit feeder market. Environmental concerns related to plastic waste and carbon emissions are prompting buyers to seek suppliers who prioritize sustainable materials and practices. For instance, feeders made from recycled or biodegradable materials are gaining traction, appealing to both ethical considerations and regulatory compliance.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers for adherence to fair labor practices and transparency in sourcing. This shift is not only about moral responsibility but also about brand reputation; companies that engage in ethical sourcing often enjoy increased customer loyalty and trust.

Illustrative image related to automatic rabbit feeder

Furthermore, acquiring ‘green’ certifications can provide a competitive edge in the marketplace. Certifications such as FSC (Forest Stewardship Council) or similar eco-labels signal a commitment to sustainability, making products more attractive to environmentally conscious consumers and businesses alike. For B2B buyers, aligning with suppliers who embrace these values can enhance their market positioning and appeal to a broader customer base.

How Has the Automatic Rabbit Feeder Market Evolved Over Time?

The evolution of the automatic rabbit feeder market reflects broader trends in agriculture and pet care. Initially, feeders were rudimentary, often hand-crafted and designed for basic functionality. However, as the demand for efficiency and convenience grew, manufacturers began to innovate.

The introduction of automated features marked a significant turning point. Early models incorporated simple mechanisms for timed feeding, while modern iterations now boast advanced technology, including sensors and connectivity options. This transformation has allowed for more precise feeding schedules and better management of rabbit health, aligning with the increasing emphasis on animal welfare.

Illustrative image related to automatic rabbit feeder

As consumer preferences shifted towards sustainability and ethical sourcing, manufacturers have adapted by incorporating eco-friendly materials and transparent supply chains. This ongoing evolution not only enhances product functionality but also ensures that suppliers can meet the diverse needs of a global market increasingly focused on sustainability and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic rabbit feeder

-

How do I choose the right automatic rabbit feeder for my business?

Choosing the right automatic rabbit feeder involves considering factors such as the size of your operation, the type of feed you use, and your budget. Evaluate feeders based on their capacity, durability, and ease of use. Look for models that minimize feed waste and are easy to clean, as hygiene is crucial in animal husbandry. Additionally, consider suppliers who offer customization options to meet specific needs, such as feeder size or material, which can enhance the efficiency of your feeding system. -

What features should I look for in an automatic rabbit feeder?

When sourcing an automatic rabbit feeder, prioritize features such as adjustable feeding portions, weather-resistant materials, and easy-to-refill designs. Look for feeders with anti-jamming mechanisms to prevent clogs and ensure smooth operation. Also, consider units that are easy to disassemble for cleaning and maintenance. Advanced models may offer programmable feeding schedules, which can be particularly beneficial for larger operations aiming to optimize feeding times and reduce labor costs. -

What are the typical minimum order quantities (MOQs) for automatic rabbit feeders?

Minimum order quantities for automatic rabbit feeders can vary significantly between suppliers. Generally, MOQs can range from a few units for smaller manufacturers to several hundred for larger, established companies. When negotiating, consider your storage capabilities and projected sales volume. Suppliers may be willing to adjust MOQs based on your commitment to future orders or offer discounts for bulk purchases, which can lead to cost savings in the long run. -

How can I vet suppliers for automatic rabbit feeders?

To vet suppliers effectively, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from other B2B buyers. Assess their production capabilities, quality assurance processes, and certifications relevant to animal welfare and food safety. Request samples to evaluate the product quality firsthand. Additionally, consider visiting their facilities if possible, or using third-party inspection services, especially when sourcing from international markets. -

What payment terms should I expect when purchasing automatic rabbit feeders?

Payment terms can vary widely among suppliers, especially in international transactions. Common terms include a deposit (often 30%) upfront, with the balance due upon shipment or delivery. Some suppliers may offer favorable terms such as net 30 or net 60 days for established relationships. It’s crucial to clarify payment methods accepted (e.g., wire transfer, credit card) and to understand any currency conversion fees involved, especially when dealing with international suppliers. -

What are the shipping and logistics considerations for importing automatic rabbit feeders?

Shipping and logistics are critical factors when importing automatic rabbit feeders. Consider shipping costs, delivery timelines, and customs duties applicable in your country. Work with suppliers who can provide reliable freight forwarding services or partner with logistics companies experienced in handling agricultural equipment. Ensure that your chosen shipping method aligns with your budget and timeline. Understanding local regulations and import restrictions will also help prevent delays and additional costs. -

How do I ensure quality assurance for automatic rabbit feeders?

Quality assurance is vital for maintaining product standards. Request detailed product specifications and quality control processes from your suppliers. It may be beneficial to establish a third-party inspection agreement to verify product quality before shipment. Additionally, inquire about warranties or return policies that protect your investment. Regular communication with suppliers and feedback from end-users can also help maintain quality standards over time. -

Can I customize the design of automatic rabbit feeders for my specific needs?

Many suppliers offer customization options for automatic rabbit feeders to meet specific operational requirements. Customizations can include size adjustments, material selection, and features such as integrated water dispensers or specific feeding mechanisms. When discussing customization, provide clear specifications and any design preferences. Be prepared for potential lead times that may vary based on the complexity of the modifications and the supplier’s production schedule.

Top 4 Automatic Rabbit Feeder Manufacturers & Suppliers List

1. Bass Equipment – Rabbit Feeders

Domain: bassequipment.com

Registered: 1998 (27 years)

Introduction: Rabbit Feeder options include: Pro-B Feed Saver Feeder ($3.40 – $8.35), Bass Creep Feeder ($9.65 – $12.45), Bass “Econo” Hayrack ($5.95 – $6.20), E-Z FEEDER ($7.20 – $7.95), Bass Hay/Pellet Combo Feeder ($7.25 – $8.15), Standard Bass Solid Bottom Feeder ($4.80 – $5.80), Bass Fine-x II Feeders ($6.20 – $6.75), Bass Perforated Slotted Rabbit Feeder ($6.50 – $7.90), Bass Fine-x Feeders ($5.85 – $7.10…

2. Stone Family Farmstead – DIY Rabbit Feeder

Domain: stonefamilyfarmstead.com

Registered: 2015 (10 years)

Introduction: DIY rabbit feeder made from food grade plastic peanut containers and thicker plastic flat bowls; requires a large square plastic container with a screw-top lid, sharp knife or scissors, wide shallow plastic container, and rabbit food; designed to provide continuous food for rabbits; suitable for short breaks away from home.

3. RabbitTalk – High Capacity Feeders

Domain: rabbittalk.com

Registered: 2009 (16 years)

Introduction: High capacity or semi-automatic feeders for rabbits; ideas discussed include using larger J-feeders, extensions made from cardboard or metal, and PVC pipes to increase feed capacity; suggestions for gravity-fed systems using plastic bottles; focus on creating solutions for standard all-wire, 36″ x 24″ hanging cage rabbitry.

4. Petwant – Pet Automatic Feeder F15

Domain: petwant.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Petwant Pet Automatic Feeder”, “Model”: “F15”, “Capacity”: “1.8L”, “Features”: {“Scheduled Feeding”: “4 meals per day (APP version allows 10 meals per day)”, “Kibble Size Compatibility”: “Up to 30mm”, “Food Outlets”: “2 (1 for 20mm kibble, 1 for 30mm kibble)”, “Camera”: “2 Million Pixels HD Camera with 1080P”, “Two-Way Audio”: “Yes”, “Food Freshness”: “Built-in desiccant box with…

Strategic Sourcing Conclusion and Outlook for automatic rabbit feeder

As the global demand for sustainable and efficient animal husbandry solutions grows, strategic sourcing of automatic rabbit feeders presents a significant opportunity for international B2B buyers. By investing in high-quality feeders, businesses can enhance operational efficiency, reduce labor costs, and improve animal welfare. The diverse range of automatic feeders available—from gravity-fed designs to more sophisticated electronic systems—allows buyers to select products tailored to their specific needs and regional requirements.

It is crucial for buyers, particularly from Africa, South America, the Middle East, and Europe, to evaluate suppliers based on quality, durability, and after-sales support. Establishing relationships with reputable manufacturers can lead to better pricing, timely delivery, and reliable customer service, which are essential in maintaining a competitive edge in the market.

Looking ahead, the integration of technology in feeding systems is likely to expand, with innovations such as smart feeders that monitor feed levels and rabbit health. B2B buyers should stay informed about these advancements and consider how they can leverage them to optimize their operations. Now is the time to take action—explore your options for automatic rabbit feeders and invest in solutions that will propel your business into a sustainable future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to automatic rabbit feeder