Introduction: Navigating the Global Market for no water in the fountain

In the realm of outdoor aesthetics, the challenge of managing “no water in the fountain” scenarios presents a significant concern for international B2B buyers. Whether you are sourcing decorative fountains for hotels, parks, or private estates, understanding the nuances of water features is essential for maintaining their charm and functionality. This guide delves into the various types of fountains, their applications, and the critical factors influencing their operation, such as evaporation rates, splashing, and potential leaks.

Buyers from diverse regions, including Africa, South America, the Middle East, and Europe—countries like Brazil and Nigeria—will find valuable insights on supplier vetting, cost considerations, and maintenance strategies. By addressing common issues and providing practical solutions, this guide empowers businesses to make informed purchasing decisions that enhance their outdoor spaces while minimizing operational headaches.

In a global market where aesthetics meet functionality, ensuring your fountain remains a captivating centerpiece is crucial. With the right knowledge and resources, you can navigate the complexities of fountain management and secure products that will stand the test of time.

Table Of Contents

- Top 2 No Water In The Fountain Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for no water in the fountain

- Understanding no water in the fountain Types and Variations

- Key Industrial Applications of no water in the fountain

- 3 Common User Pain Points for ‘no water in the fountain’ & Their Solutions

- Strategic Material Selection Guide for no water in the fountain

- In-depth Look: Manufacturing Processes and Quality Assurance for no water in the fountain

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘no water in the fountain’

- Comprehensive Cost and Pricing Analysis for no water in the fountain Sourcing

- Alternatives Analysis: Comparing no water in the fountain With Other Solutions

- Essential Technical Properties and Trade Terminology for no water in the fountain

- Navigating Market Dynamics and Sourcing Trends in the no water in the fountain Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of no water in the fountain

- Strategic Sourcing Conclusion and Outlook for no water in the fountain

- Important Disclaimer & Terms of Use

Understanding no water in the fountain Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Power Failure | Fountain stops due to lack of electrical supply | Commercial landscaping, event venues | Pros: Quick fix; minimal cost. Cons: Downtime can affect aesthetics. |

| Water Level Issues | Insufficient water due to evaporation or leaks | Hospitality, residential complexes | Pros: Easy to monitor; regular maintenance can prevent issues. Cons: Requires ongoing water supply and attention. |

| Mechanical Failures | Problems with the pump or impeller leading to no water flow | Parks, public spaces, and fountains | Pros: Durable components; potential for long-term use. Cons: Repairs can be costly and time-consuming. |

| Environmental Factors | Impact of weather conditions like wind or extreme heat on water loss | Outdoor events, public installations | Pros: Enhances outdoor ambiance; customizable solutions. Cons: Requires strategic placement and ongoing management. |

| Structural Damage | Cracks or leaks in the fountain structure causing water loss | Municipal fountains, large installations | Pros: Aesthetic appeal; can be repaired. Cons: Repair costs can be high; may require professional services. |

What Are the Characteristics of Power Failure in Fountains?

Power failure is a common issue that can lead to a complete halt in fountain operation. This can occur due to faulty wiring, blown fuses, or tripped circuit breakers. For B2B buyers in commercial landscaping and event venues, ensuring a reliable electrical supply is crucial to maintaining the aesthetic and functional appeal of fountains. Regular checks and maintenance of electrical connections can prevent power-related issues, minimizing downtime.

How Do Water Level Issues Affect Fountain Functionality?

Water level issues arise from evaporation, leaks, or inadequate water supply. These problems can lead to pump damage if not addressed promptly. Businesses in hospitality and residential complexes must be proactive in monitoring water levels to maintain the visual and auditory appeal of their fountains. Implementing automated water level monitoring systems can help streamline maintenance and reduce manual oversight.

What Are the Implications of Mechanical Failures in Fountains?

Mechanical failures, particularly related to the pump or impeller, can significantly disrupt fountain operation. These components are vital for water circulation and flow, and their malfunction can lead to a complete stop in water movement. For parks and public spaces, investing in high-quality pumps and establishing a regular maintenance schedule can mitigate the risk of mechanical failures, ensuring consistent performance and reducing repair costs.

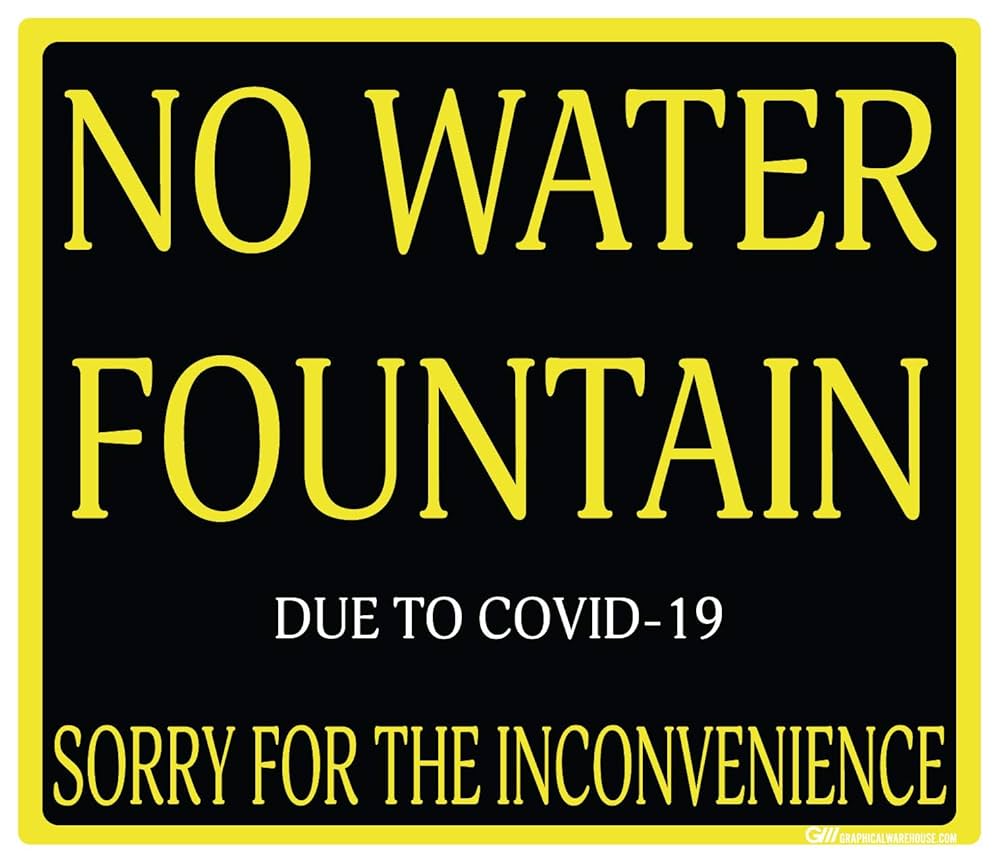

Illustrative image related to no water in the fountain

How Do Environmental Factors Impact Fountain Water Levels?

Environmental factors, including wind and extreme temperatures, can lead to increased evaporation and splashing, resulting in water loss. For outdoor events and public installations, strategic placement of fountains, along with the use of covers or shade structures, can help maintain water levels. B2B buyers should consider these factors when designing outdoor spaces to ensure the longevity and efficiency of their fountains.

What Should Buyers Consider Regarding Structural Damage?

Structural damage, such as cracks or leaks, can severely affect the functionality of fountains. This issue is often caused by weathering or material fatigue over time. Municipalities and businesses managing large installations should prioritize regular inspections and maintenance to identify and address structural issues early. Investing in durable materials and professional repair services can enhance the lifespan of fountain structures, ultimately providing better ROI.

Key Industrial Applications of no water in the fountain

| Industry/Sector | Specific Application of no water in the fountain | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Landscaping & Garden Design | Decorative features in parks and public spaces | Enhances aesthetic appeal without maintenance costs | Durable materials that withstand various weather conditions |

| Hospitality & Tourism | Waterless fountains in hotels and resorts | Creates serene environments with low upkeep | Design adaptability to match architectural styles |

| Retail & Commercial Spaces | Interactive displays in shopping malls | Attracts foot traffic and enhances customer experience | Customization options for branding and visual impact |

| Agriculture | Evaporative cooling systems in greenhouses | Reduces water usage while maintaining humidity | Energy-efficient systems that comply with local regulations |

| Education | Educational tools for environmental awareness | Promotes sustainability practices among students | Interactive elements that engage and educate |

How Are ‘No Water in the Fountain’ Applications Used in Various Industries?

In the landscaping and garden design sector, no water in the fountain applications are increasingly popular for decorative features in parks and public spaces. These installations enhance aesthetic appeal while significantly reducing maintenance costs associated with traditional water fountains. Buyers in this sector should prioritize durable materials that can withstand various weather conditions, ensuring longevity and minimal upkeep.

Illustrative image related to no water in the fountain

Within the hospitality and tourism industry, waterless fountains serve as serene environments in hotels and resorts. They offer a tranquil atmosphere that enhances guest experiences without the high maintenance demands of water features. Buyers should consider design adaptability to ensure that these fountains align with the architectural styles of their properties, creating a cohesive aesthetic.

In retail and commercial spaces, interactive displays utilizing no water fountains attract foot traffic and enhance the customer experience. These installations can be customized to reflect the branding of the business, making them a strategic investment for increasing engagement. Sourcing considerations should include customization options that allow for unique designs and visual impact, which can differentiate a brand in competitive markets.

The agriculture sector benefits from evaporative cooling systems that utilize no water in the fountain principles. These systems help maintain humidity levels in greenhouses while significantly reducing overall water usage. Buyers should look for energy-efficient systems that comply with local regulations, ensuring sustainability and cost-effectiveness in their operations.

Finally, in the education sector, no water fountains can serve as educational tools to promote environmental awareness among students. These installations can engage students through interactive elements that demonstrate water conservation practices. Sourcing should focus on features that not only educate but also inspire sustainable practices within the school community, fostering a culture of environmental responsibility.

3 Common User Pain Points for ‘no water in the fountain’ & Their Solutions

Scenario 1: Power Supply Failures Impacting Fountain Operations

The Problem: B2B buyers managing commercial properties often rely on outdoor fountains to enhance the aesthetic appeal of their locations. However, when a fountain suddenly stops flowing due to power supply issues, it can lead to a loss of ambiance and potential customer dissatisfaction. This challenge is particularly acute in regions with inconsistent electricity supply, such as parts of Africa and South America, where even minor power fluctuations can disrupt fountain operations. It can be frustrating for property managers to troubleshoot electrical issues, especially when they must balance aesthetics and operational efficiency.

The Solution: To mitigate power supply problems, invest in reliable power management solutions. Begin by ensuring that all fountains are connected to a GFCI outlet, which provides protection against ground faults. Regularly test these outlets and consider using surge protectors to guard against power spikes. Additionally, consider installing backup power systems such as generators or solar-powered solutions tailored for fountains. This approach not only ensures continuous operation but can also be a selling point for eco-conscious clients. Moreover, maintaining a service contract with a qualified electrician can expedite repairs and minimize downtime, ensuring your fountain remains a stunning focal point for visitors.

Scenario 2: Insufficient Water Levels Causing Fountain Malfunctions

The Problem: A common issue for B2B buyers is the insufficient water level in fountains, which can arise from evaporation or splashing. In hot climates, such as those in parts of the Middle East and Southern Europe, water can evaporate quickly, leading to inadequate water levels. This not only causes the fountain to malfunction but also increases maintenance costs as pumps can become damaged when they run dry. Property managers may find themselves frequently refilling the fountain, which is both labor-intensive and costly.

The Solution: To combat low water levels, implement a regular maintenance schedule that includes weekly checks on water levels and topping off as necessary. Educate staff on the importance of monitoring the fountain, especially during hot weather. Consider installing an automatic water fill system that can be connected to a water source, ensuring the fountain is always filled to the proper level. Additionally, using a cover during off-peak seasons can help minimize evaporation rates. For regions prone to high temperatures, incorporating shade structures or surrounding vegetation can also reduce direct sunlight exposure, ultimately preserving water levels and enhancing the fountain’s longevity.

Scenario 3: Leak Detection and Repair Challenges

The Problem: Leaks in fountains pose a significant challenge for B2B buyers, especially those managing large installations in commercial spaces. A leaking fountain not only leads to water waste but can also create potential safety hazards, such as slippery surfaces. In areas with limited water resources, like parts of Africa and the Middle East, the implications of water loss can be severe, impacting operational budgets and sustainability initiatives. Detecting and repairing leaks can be a complex process, often requiring specialized knowledge and tools.

The Solution: Establish a proactive leak detection and maintenance protocol. Regularly inspect fountains for visible signs of wear, such as cracks or loose fittings, and consider conducting annual comprehensive checks with professionals experienced in fountain maintenance. For minor repairs, employing waterproof sealants specifically designed for the fountain’s material can be effective. Additionally, integrating leak detection sensors that can alert maintenance teams to drops in water levels can help catch issues early. By adopting these practices, property managers can significantly reduce water loss, ensure safety, and maintain the aesthetic value of their fountains, leading to a more sustainable operation.

Strategic Material Selection Guide for no water in the fountain

What Are the Key Materials for No Water in Fountains?

When selecting materials for fountains designed to operate without water, it’s essential to consider factors such as durability, resistance to environmental conditions, and overall cost-effectiveness. Here, we analyze four common materials: fiberglass, concrete, stainless steel, and polymer composites, each with unique properties and implications for B2B buyers.

How Does Fiberglass Perform in No Water Fountain Applications?

Fiberglass is a popular choice for fountain construction due to its lightweight nature and corrosion resistance. It can withstand varying temperatures and pressures, making it suitable for diverse climates. Fiberglass is also resistant to UV light, which helps maintain its aesthetic appeal over time.

Pros: Fiberglass is highly durable and easy to mold into intricate designs, making it ideal for decorative fountains. It typically has a lower manufacturing complexity compared to other materials, allowing for quicker production times.

Cons: While fiberglass is generally cost-effective, it may not provide the same structural strength as concrete or metal options. Additionally, it can be prone to scratching and may require periodic maintenance to keep its appearance.

Impact on Application: Fiberglass fountains can be designed to fit various aesthetics and environments, but care must be taken to ensure they are not exposed to extreme physical impacts.

Considerations for International Buyers: Buyers in regions such as Africa and South America should ensure compliance with local regulations regarding materials used in outdoor installations. Fiberglass may need to meet specific standards for UV resistance and environmental impact.

What Are the Advantages of Concrete for No Water Fountains?

Concrete is a traditional material known for its strength and durability. It can withstand high pressures and is resistant to various environmental factors, including temperature fluctuations and moisture.

Pros: Concrete is highly durable and can be cast into virtually any shape, allowing for significant design flexibility. It also provides excellent stability and can be finished in various ways to enhance aesthetic appeal.

Cons: The manufacturing process for concrete can be complex and time-consuming, leading to higher costs. Additionally, concrete is heavy, which can complicate transportation and installation.

Impact on Application: Concrete fountains are suitable for permanent installations and can be designed to handle significant loads. However, they may require sealing to prevent water absorption and damage over time.

Considerations for International Buyers: Buyers should check for compliance with local construction standards, such as ASTM or DIN, particularly regarding load-bearing capabilities and environmental impact.

How Does Stainless Steel Compare for No Water Fountains?

Stainless steel is favored for its modern look and exceptional corrosion resistance. It can withstand high temperatures and is easy to clean, making it ideal for low-maintenance applications.

Pros: The durability of stainless steel ensures a long lifespan with minimal maintenance. It is also highly resistant to rust and corrosion, which is beneficial in humid or coastal environments.

Cons: Stainless steel can be more expensive than other materials, and its manufacturing process may involve complex fabrication techniques. Additionally, it can be prone to scratching, which may affect its appearance over time.

Impact on Application: Stainless steel is suitable for contemporary fountain designs and can be used in various settings, including commercial spaces. However, its reflective surface may require regular cleaning to maintain its aesthetic.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure that stainless steel products meet local standards for corrosion resistance and environmental sustainability.

What Role Do Polymer Composites Play in No Water Fountain Design?

Polymer composites are increasingly being used in fountain construction due to their lightweight properties and resistance to environmental factors. They can be engineered to meet specific performance criteria, including temperature and pressure ratings.

Pros: These materials are highly versatile and can be designed to mimic other materials, such as stone or metal, while being lighter and easier to handle. They also offer excellent resistance to UV light and chemical exposure.

Cons: The initial cost of polymer composites can be higher than traditional materials, and their long-term durability may not match that of concrete or stainless steel.

Impact on Application: Polymer composites can be tailored for specific aesthetic and functional requirements, making them suitable for a variety of fountain designs.

Considerations for International Buyers: Buyers should verify that polymer composites comply with local environmental regulations and standards, particularly in regions with strict sustainability requirements.

Summary Table of Material Comparisons

| Material | Typical Use Case for no water in the fountain | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fiberglass | Decorative garden fountains | Lightweight and corrosion-resistant | Prone to scratching | Medium |

| Concrete | Permanent outdoor installations | High durability and design flexibility | Heavy and complex to manufacture | High |

| Stainless Steel | Modern aesthetic fountains | Long lifespan with low maintenance | Higher cost and prone to scratching | High |

| Polymer Composites | Versatile, lightweight designs | Customizable and UV resistant | Higher initial cost | Medium |

This strategic material selection guide provides actionable insights for B2B buyers in various international markets, ensuring informed decisions when sourcing materials for no water fountains.

Illustrative image related to no water in the fountain

In-depth Look: Manufacturing Processes and Quality Assurance for no water in the fountain

What Are the Key Stages in the Manufacturing Process of Fountains Designed to Avoid Water Loss?

The manufacturing process of fountains, particularly those engineered to minimize water loss, involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets quality standards and performs efficiently in various environmental conditions.

How Are Materials Prepared for Fountain Production?

The first stage, material preparation, involves sourcing high-quality materials that are resistant to weathering, UV exposure, and other environmental factors. Common materials include fiberglass, concrete, and stone, each chosen for its durability and aesthetic appeal. Suppliers often conduct preliminary tests to verify the material’s integrity and suitability for fountain construction.

Once materials are selected, they undergo processes like cutting and shaping to prepare them for the forming stage. This preparation may include treating surfaces to enhance adhesion for coatings or sealants that will be applied later.

What Techniques Are Used in Forming Fountains?

In the forming stage, advanced techniques such as molding or casting are employed to create the fountain’s structure. For instance, fiberglass fountains are typically molded using a gel-coating process, which ensures a smooth finish and water-tightness. Concrete fountains may be cast using pre-designed molds, allowing for intricate designs that can withstand heavy use.

During this phase, manufacturers pay close attention to the design specifications, ensuring that all components fit together seamlessly to prevent leaks. The use of computer-aided design (CAD) technology can help streamline this process, allowing for precise measurements and adjustments.

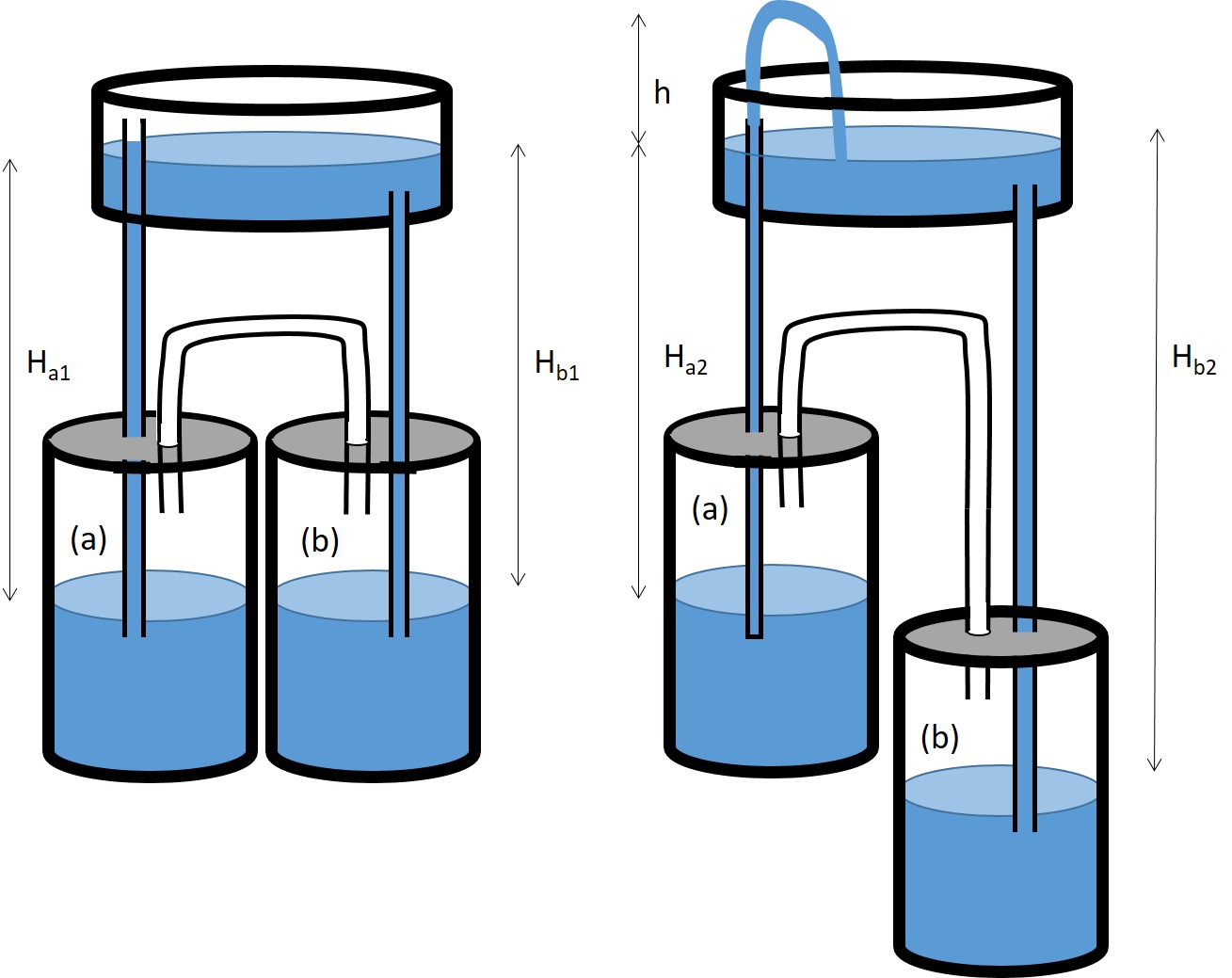

Illustrative image related to no water in the fountain

How Is Assembly Conducted for Fountains?

Assembly follows forming, where individual components are brought together. This stage often includes the installation of pumps, tubing, and filtration systems that are essential for fountain functionality. A critical aspect of assembly is ensuring that all connections are secure and water-tight to mitigate any risk of leaks.

Quality control checks during assembly are essential. Manufacturers will often perform initial tests to confirm that pumps are functioning correctly and that water flows as intended through the fountain’s design.

What Finishing Processes Are Essential for Fountain Quality?

The finishing stage involves applying protective coatings and sealants to enhance the fountain’s durability and aesthetic appeal. These finishes are designed to protect against algae growth, UV damage, and environmental wear. The application of sealants is particularly crucial for ensuring that the fountain remains water-tight.

Manufacturers may also conduct aesthetic inspections during this phase, ensuring that the visual quality meets branding and customer expectations. This can involve touch-ups or adjustments to color and texture.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that products meet international standards and customer expectations. For B2B buyers, understanding these QA processes is essential for selecting reliable suppliers.

Illustrative image related to no water in the fountain

What International Standards Are Relevant for Fountain Manufacturing?

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for an effective quality management system. Compliance with such standards demonstrates a commitment to quality and continuous improvement, which is crucial for international B2B transactions.

Other relevant certifications may include CE marking for compliance with European safety standards and API (American Petroleum Institute) certifications for pumps used in fountains. These certifications help ensure that products are safe, reliable, and environmentally friendly.

What Are the Key Quality Control Checkpoints in Fountain Manufacturing?

Quality control checkpoints are established at various stages of the manufacturing process. These typically include:

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing to monitor compliance with design specifications and identify defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product, including functionality tests, water-tightness assessments, and aesthetic evaluations.

What Common Testing Methods Are Used to Ensure Fountain Quality?

Common testing methods include pressure testing for leaks, flow rate assessments for pumps, and visual inspections for surface defects. Manufacturers may also conduct durability tests, simulating environmental conditions to evaluate how well the fountain withstands wear and tear.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

Illustrative image related to no water in the fountain

What Audit Processes Should Buyers Consider?

Buyers should consider conducting audits of potential suppliers to assess their manufacturing and quality assurance practices. This can involve reviewing production facilities, evaluating compliance with international standards, and examining documentation related to previous quality control checks.

How Can Buyers Access Quality Control Reports?

Requesting quality control reports from suppliers can provide insights into their testing methodologies and results. These reports often include details about defect rates, compliance with standards, and corrective actions taken for any identified issues.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These services can conduct thorough inspections and provide detailed reports, ensuring that the products meet the specified standards before shipment.

Illustrative image related to no water in the fountain

Conclusion: Why Quality Assurance Matters for Fountain Manufacturers

In the competitive landscape of fountain manufacturing, maintaining rigorous quality assurance processes is essential for ensuring product longevity and customer satisfaction. For B2B buyers, particularly those in diverse regions, understanding the manufacturing processes and quality control measures can lead to more informed purchasing decisions. By prioritizing suppliers who adhere to international standards and demonstrate robust quality control practices, buyers can mitigate risks and ensure the successful integration of fountains into their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘no water in the fountain’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking effective solutions for addressing issues related to “no water in the fountain.” Ensuring that your fountain operates efficiently is crucial for maintaining its aesthetic appeal and functionality. This guide will help you navigate the procurement process, evaluate suppliers, and implement best practices for troubleshooting and maintaining water features.

Step 1: Assess Your Fountain’s Requirements

Understanding the specific requirements of your fountain is the first step in ensuring it operates correctly. Consider factors such as size, design, and the type of pump used. Knowing these details will help you identify the right parts and suppliers that can meet your unique needs.

- Dimensions: Measure the fountain’s dimensions to ensure compatibility with replacement parts.

- Pump Type: Identify whether your fountain uses a submersible or external pump, as this affects the sourcing of components.

Step 2: Identify Common Causes of Water Loss

Before sourcing solutions, familiarize yourself with the common causes of water loss in fountains. This understanding will guide your procurement decisions and help you communicate effectively with potential suppliers.

- Evaporation: Regularly monitor water levels, especially in hot climates, and consider sealants to reduce evaporation.

- Leaks and Cracks: Inspect for visible damage that may require immediate repair or replacement of parts.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This diligence will ensure that you partner with reliable vendors who understand your specific needs.

- Reputation: Look for suppliers with positive reviews and a proven track record in fountain maintenance and supplies.

- Certifications: Verify any industry certifications that indicate compliance with quality and safety standards.

Step 4: Request Detailed Product Information

When considering suppliers, request comprehensive product specifications and warranties. This information is vital for ensuring that the products you purchase meet your operational requirements.

- Specifications: Ensure that all components, such as pumps and sealants, are suitable for your fountain type.

- Warranty Coverage: Understand the warranty terms to protect your investment and ensure long-term support.

Step 5: Inquire About After-Sales Support

After purchasing fountain components, having access to reliable after-sales support is essential. This support can include installation guidance, troubleshooting assistance, and maintenance tips.

- Technical Support: Confirm that the supplier offers technical support or resources for troubleshooting common issues.

- Maintenance Services: Some suppliers may offer maintenance services or packages that can help you keep your fountain in optimal condition.

Step 6: Compare Pricing and Delivery Options

Finally, compare pricing among different suppliers while considering delivery times and shipping costs. Cost-effectiveness should not compromise quality, so evaluate the total cost of ownership, including potential maintenance expenses.

- Bulk Discounts: Inquire about bulk purchase discounts if you plan to procure multiple components.

- Shipping Timeframes: Ensure that delivery timelines align with your operational needs to avoid prolonged downtime.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing for “no water in the fountain,” ensuring that their purchases are both efficient and effective.

Comprehensive Cost and Pricing Analysis for no water in the fountain Sourcing

What Are the Key Cost Components for No Water in the Fountain Solutions?

When sourcing solutions for fountains that experience water loss, it’s essential to understand the various cost components that contribute to the overall pricing. These components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary materials involved typically include pump components, sealants, and structural materials like stone or fiberglass. The quality of these materials directly impacts durability and long-term performance, affecting both initial costs and potential future repairs.

-

Labor: Skilled labor is often necessary for installation and maintenance tasks. The labor cost can vary significantly based on the complexity of the fountain design and the local labor rates, which differ across regions, particularly in Africa and South America.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment depreciation. Companies in regions with higher operational costs may pass these expenses onto buyers.

-

Tooling: For custom fountains or specialized parts, the tooling costs can be substantial. Customization often requires unique molds or machinery setups that increase upfront costs.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the fountains perform well and meet safety standards. While this may add to the cost, it is crucial for minimizing future failures and associated repair costs.

-

Logistics: Shipping and handling costs can vary dramatically based on the distance and shipping method. International buyers must consider tariffs, import duties, and the potential for delays, which can all impact pricing.

-

Margin: Suppliers will include a profit margin that reflects their business model and market conditions. This can be influenced by competition and demand in specific regions.

What Factors Influence the Pricing of Fountain Solutions?

Several factors can influence the pricing of fountain solutions, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders may lead to reduced pricing per unit due to economies of scale. Suppliers often have MOQs that can affect pricing structure.

-

Specifications and Customization: Customized solutions typically incur higher costs due to additional design and manufacturing requirements. Buyers should be clear about their specifications to avoid unexpected charges.

-

Material Quality and Certifications: The choice of materials can greatly impact price. Higher-quality materials may cost more but can lead to lower maintenance costs and longer lifespan.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers with proven track records may charge more due to their quality assurance processes.

-

Incoterms: Understanding shipping terms is essential for international transactions. Incoterms can define responsibilities for shipping costs and risks, influencing overall pricing.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly from regions like Africa, South America, and the Middle East, effective negotiation strategies can lead to cost savings:

-

Research and Preparation: Understand the market rates for similar products and the supplier’s pricing structure. Knowledge of the competitive landscape can empower buyers during negotiations.

-

Total Cost of Ownership (TCO): Consider the long-term costs associated with maintenance, repairs, and operational efficiency. A higher upfront cost may be justified if it leads to lower TCO over time.

-

Leverage Volume Discounts: If planning to order multiple units, negotiate for bulk pricing. Suppliers may offer significant discounts for larger orders.

-

Discuss Payment Terms: Flexible payment terms can ease cash flow concerns and may incentivize suppliers to offer better pricing.

-

Explore Alternative Suppliers: Don’t hesitate to source from multiple suppliers. This not only provides competitive pricing but also allows for comparisons in quality and service.

Conclusion

Understanding the comprehensive cost structure and pricing influencers associated with no water in the fountain solutions is crucial for B2B buyers. By leveraging this knowledge, buyers can make informed decisions that optimize their purchasing strategies while minimizing costs. Always remember that indicative prices can vary widely based on factors like location, supplier, and market conditions, so thorough research and negotiation are essential.

Alternatives Analysis: Comparing no water in the fountain With Other Solutions

Exploring Alternative Solutions to ‘No Water in the Fountain’

In many outdoor settings, the presence of water fountains can enhance aesthetics and create a soothing atmosphere. However, when a fountain has no water, it can lead to an unsightly and unwelcoming environment. This situation presents an opportunity for businesses to explore alternative solutions that can either replace the fountain or achieve a similar effect without relying on traditional water features. Below, we compare ‘no water in the fountain’ with two viable alternatives: dry fountain technology and decorative landscape features.

Illustrative image related to no water in the fountain

| Comparison Aspect | No Water In The Fountain | Dry Fountain Technology | Decorative Landscape Features |

|---|---|---|---|

| Performance | Limited aesthetic appeal; lack of sound and movement | Provides visual appeal with light and mist effects | Offers a variety of visual enhancements without water |

| Cost | Generally low, as it requires minimal upkeep | Moderate to high, depending on installation and technology used | Low to moderate, depending on materials and design |

| Ease of Implementation | Simple, often requires minimal setup | Requires professional installation and technical expertise | Can be DIY or professionally installed, depending on complexity |

| Maintenance | Minimal maintenance required | Regular maintenance needed for technology upkeep | Low maintenance, primarily seasonal adjustments |

| Best Use Case | Temporary solution or when water supply is limited | Ideal for public spaces where water features are desired without water | Great for gardens, parks, and commercial spaces looking for sustainable options |

What Are the Advantages and Disadvantages of Dry Fountain Technology?

Dry fountain technology utilizes advanced mechanisms to create visual effects, such as light projections and mist, without the use of water. This alternative can replicate the aesthetic appeal of traditional fountains while eliminating water-related maintenance issues such as cleaning, refilling, and preventing algae growth. However, the initial investment can be substantial, and ongoing maintenance may require specialized knowledge, making it less accessible for smaller businesses or budget-conscious buyers.

How Do Decorative Landscape Features Compare?

Decorative landscape features, such as rocks, sculptures, or planter boxes, offer a versatile alternative to water fountains. They can enhance the visual appeal of a space without the complications associated with water features. These elements can be customized to fit various designs and themes, allowing for creative expression in outdoor environments. The main downside is that they do not provide the same soothing sound or dynamic movement that water offers, which may be a critical factor for some buyers.

How Should B2B Buyers Choose the Right Solution for Their Needs?

When considering alternatives to a fountain with no water, B2B buyers should assess their specific needs, budget, and the intended use of the space. If the primary goal is to maintain a tranquil ambiance, dry fountain technology might be worth the investment. Conversely, if cost-effectiveness and low maintenance are priorities, decorative landscape features may be more suitable. Ultimately, the choice should align with the overall aesthetic and functional goals of the environment in which they are implemented. By weighing these factors carefully, businesses can select the most effective solution to enhance their outdoor spaces.

Illustrative image related to no water in the fountain

Essential Technical Properties and Trade Terminology for no water in the fountain

What Are the Key Technical Properties to Consider for Fountains with No Water?

Understanding the essential technical properties of fountains is crucial for B2B buyers, especially when dealing with installations that experience water loss. Here are some critical specifications:

1. Material Grade

The material grade of a fountain can significantly affect its durability and resistance to environmental factors. Common materials include fiberglass, concrete, and natural stone. Higher-grade materials typically offer better longevity and aesthetic appeal, which is vital for maintaining a fountain’s functionality and visual impact over time.

2. Flow Rate

Flow rate, measured in gallons per hour (GPH), indicates how much water a pump can circulate. This is important for ensuring that fountains maintain adequate water levels and that the water features operate effectively. A higher flow rate may lead to excessive splashing, so understanding the optimal flow rate for specific fountain designs is essential for preventing water loss.

3. Pump Power

The power of the pump, usually measured in watts, determines its efficiency in circulating water. An adequately powered pump is necessary for maintaining consistent water flow and preventing issues like dry running, which can damage the pump. Buyers should ensure that the pump’s power is compatible with the fountain’s size and design requirements.

4. Reservoir Capacity

The capacity of the reservoir directly impacts how long a fountain can operate before requiring a refill. A larger reservoir can help mitigate issues related to evaporation and frequent refilling, particularly in hot climates. Understanding reservoir capacity is crucial for ensuring that fountains remain functional and aesthetically pleasing without constant maintenance.

5. Sealant Quality

The quality of the sealant used in constructing the fountain is vital for preventing leaks and maintaining water levels. High-quality sealants can resist weather conditions and prevent cracking, ensuring long-term durability. Buyers should inquire about the types of sealants used in the fountain’s construction to avoid future issues.

What Common Trade Terms Should B2B Buyers Know Regarding Fountains?

Familiarizing yourself with industry jargon can enhance communication and negotiation with suppliers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the fountain industry, OEM suppliers often provide pumps and components that are critical for fountain functionality. Understanding this term can help buyers identify quality sources for parts.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory levels effectively and avoid overcommitting to products that may not sell.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and terms from suppliers for specific products. Buyers should prepare detailed RFQs that specify their requirements to receive accurate quotes and streamline the procurement process.

Illustrative image related to no water in the fountain

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of sellers and buyers in shipping agreements. Understanding these terms is critical for B2B buyers to clarify who is responsible for shipping costs, insurance, and delivery timelines, especially when sourcing from international suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving it. This is crucial for planning installation projects and ensuring that fountains are delivered on schedule. Buyers should discuss lead times with suppliers to align project timelines accordingly.

6. Warranty Period

The warranty period is the time frame during which a manufacturer guarantees the quality and performance of their product. Understanding warranty terms is essential for buyers to protect their investments and to ensure they have recourse in case of defects or issues with fountain components.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance the longevity and effectiveness of their fountain installations.

Navigating Market Dynamics and Sourcing Trends in the no water in the fountain Sector

What Are the Global Drivers Shaping the No Water in the Fountain Market?

The no water in the fountain sector is increasingly influenced by several global drivers that affect B2B sourcing and purchasing decisions. The growing trend of urbanization, particularly in regions like Africa, South America, and the Middle East, has led to a rising demand for aesthetically pleasing outdoor solutions that require minimal maintenance. As cities expand, the integration of innovative water features, such as disappearing fountains, appeals to urban planners and landscape architects looking to enhance public spaces without compromising water resources.

Illustrative image related to no water in the fountain

Emerging technologies, such as smart pumps and remote monitoring systems, are also transforming the fountain market. These advancements enable real-time monitoring of water levels and pump performance, significantly reducing the risk of operational failures and enhancing user experience. B2B buyers are increasingly interested in solutions that not only save water but also provide insights into maintenance needs, thereby optimizing operational costs.

Additionally, as environmental concerns gain traction globally, there’s a heightened focus on sourcing sustainable products. Buyers are now looking for suppliers who can provide eco-friendly materials and systems designed to minimize water usage while maintaining aesthetic appeal.

How Are Sustainability and Ethical Sourcing Impacting the No Water in the Fountain Sector?

Sustainability has become a cornerstone of purchasing decisions in the no water in the fountain sector. As international markets become more environmentally conscious, the demand for products that minimize ecological impact is rising. B2B buyers are increasingly prioritizing suppliers who utilize sustainable materials and practices, ensuring that their purchases align with their corporate social responsibility goals.

The environmental impact of traditional fountains, which often consume significant water resources, has led to a shift towards no water in the fountain solutions. These designs not only conserve water but also reduce the need for extensive maintenance and chemical treatments, making them more attractive to eco-conscious buyers. Furthermore, the use of ‘green’ certifications and materials, such as recycled metals and biodegradable sealants, is becoming a key consideration for suppliers aiming to capture this growing market segment.

Illustrative image related to no water in the fountain

Ethical supply chains are equally important, as B2B buyers seek transparency in the sourcing of materials. Ensuring that suppliers adhere to fair labor practices and responsible sourcing can enhance brand reputation and foster trust among consumers, especially in regions where ethical sourcing is increasingly scrutinized.

What Is the Historical Context of the No Water in the Fountain Market?

The concept of fountains dates back thousands of years, with ancient civilizations using them not only for aesthetics but also for practical purposes, such as water supply. However, the no water in the fountain trend has gained prominence in recent decades, largely in response to water scarcity issues and the need for sustainable landscaping solutions. This evolution reflects a broader societal shift towards conservation and efficiency, particularly in urban environments where water resources are becoming increasingly strained.

In the past, traditional fountains often required significant water resources and maintenance, leading to operational challenges for municipalities and businesses alike. The introduction of no water designs has revolutionized the market, providing an attractive alternative that aligns with contemporary environmental values while still delivering the visual and auditory benefits of flowing water. This historical shift underscores the growing importance of innovation and sustainability in B2B purchasing decisions within the fountain sector.

Frequently Asked Questions (FAQs) for B2B Buyers of no water in the fountain

-

How do I solve the problem of no water in my fountain?

To address the issue of no water in your fountain, first check the power supply to ensure the pump is operational. Verify that the tubing is securely connected and that there are no blockages at the pump’s intake. Inspect the water level in the reservoir; if it’s low, refill it to ensure adequate flow. Additionally, examine the pump’s impeller for any damage and clean or replace it if necessary. Regular maintenance can prevent this issue from recurring. -

What is the best maintenance practice for water fountains?

The best maintenance practice for water fountains includes regular checks on water levels, ensuring the pump is functioning correctly, and cleaning the fountain surfaces to prevent algae buildup. It’s advisable to use a safe algaecide to maintain water quality. Additionally, inspect for leaks or cracks in the fountain structure and address any issues promptly. Consider seasonal maintenance adjustments, especially in regions with extreme weather, to protect the fountain from freezing or excessive evaporation. -

What factors should I consider when sourcing fountains for my business?

When sourcing fountains for your business, consider the quality of materials used, the supplier’s reputation, and their capacity for customization. Evaluate the design options available and whether they align with your market’s preferences. Additionally, assess the supplier’s logistics capabilities, including shipping times and costs. It’s crucial to establish clear communication regarding warranties and after-sales support to ensure a smooth procurement process. -

What is the minimum order quantity (MOQ) for fountains?

Minimum order quantities (MOQ) for fountains can vary significantly between suppliers. Generally, MOQs may range from a few units to several dozen, depending on the manufacturer’s production capabilities and the complexity of the fountain designs. When negotiating with suppliers, clarify the MOQ upfront to ensure it aligns with your purchasing strategy and budget. Some suppliers may offer flexibility on MOQs for first-time buyers or bulk orders. -

How do I ensure quality assurance when purchasing fountains?

To ensure quality assurance when purchasing fountains, request samples or detailed product specifications from suppliers. Establish a clear set of quality standards and communicate these expectations before placing an order. Consider conducting factory visits or utilizing third-party inspection services to verify product quality during production. Additionally, ensure that your supplier provides warranties and return policies that protect your investment. -

What payment terms are common in international fountain transactions?

Common payment terms in international fountain transactions include options like upfront payments, letter of credit, or payment upon delivery. Suppliers may also offer installment plans based on production milestones. It’s essential to negotiate terms that provide security for both parties. Ensure you understand any currency exchange implications and potential fees associated with international transactions to avoid unexpected costs. -

How do seasonal changes affect fountain maintenance and sourcing?

Seasonal changes can significantly impact fountain maintenance and sourcing. In regions with cold winters, it’s essential to winterize fountains to prevent damage from freezing temperatures. During hot seasons, evaporation rates increase, requiring more frequent water replenishment. When sourcing, consider seasonal demand fluctuations, as suppliers may have varying lead times based on production schedules. Adjust your inventory and maintenance plans accordingly to ensure year-round functionality. -

What are the logistics considerations for importing fountains?

Logistics considerations for importing fountains include evaluating shipping methods, costs, and customs regulations specific to your region. Understand the lead times for production and shipping, and factor in potential delays at customs. It’s also crucial to assess the supplier’s capability to handle logistics efficiently, including packaging that minimizes damage during transport. Collaborating with a reliable freight forwarder can streamline the import process and ensure timely delivery of your fountains.

Top 2 No Water In The Fountain Manufacturers & Suppliers List

1. Facebook – Support Fix

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Support Fix, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. The Blissful Place – Best Selling Fountains

Domain: theblissfulplace.com

Registered: 2020 (5 years)

Introduction: Fountain Types: Best Selling Fountains, Animal Fountains, Bird Bath Fountains, Buddha Water Fountains, Corner Outdoor Fountains, Dolphin Fountains, Driveway Fountains, Floor Outdoor Fountains, Fountain Statues, Frog Fountains, Lady Fountains, Lionhead Fountains, Outdoor Bubbler Fountains, Outdoor Fountains with Pools, Outdoor Wall Fountains, Sphere Water Fountains, Tabletop Fountains, Tiered Fount…

Strategic Sourcing Conclusion and Outlook for no water in the fountain

In summary, addressing the issue of “no water in the fountain” requires a comprehensive understanding of both the operational and environmental factors that contribute to fountain functionality. Strategic sourcing plays a pivotal role in ensuring that businesses have access to high-quality components and maintenance services that minimize downtime and enhance the longevity of water features. By investing in reliable suppliers and adopting preventive maintenance practices, international B2B buyers can mitigate risks associated with water loss, such as evaporation, leaks, and equipment failure.

Moreover, as the global demand for aesthetically pleasing outdoor spaces continues to rise, particularly in regions like Africa, South America, the Middle East, and Europe, the importance of maintaining functional fountains cannot be overstated. Buyers are encouraged to prioritize partnerships with manufacturers and service providers that offer not only quality products but also expertise in fountain maintenance and troubleshooting.

Looking ahead, the integration of innovative technologies and sustainable practices in fountain design and maintenance will be crucial. By embracing these trends, businesses can enhance their offerings and meet the evolving expectations of their clientele. Take proactive steps today to ensure that your water features remain a captivating focal point in your landscapes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.